Brand: LANE

Production line advantages:

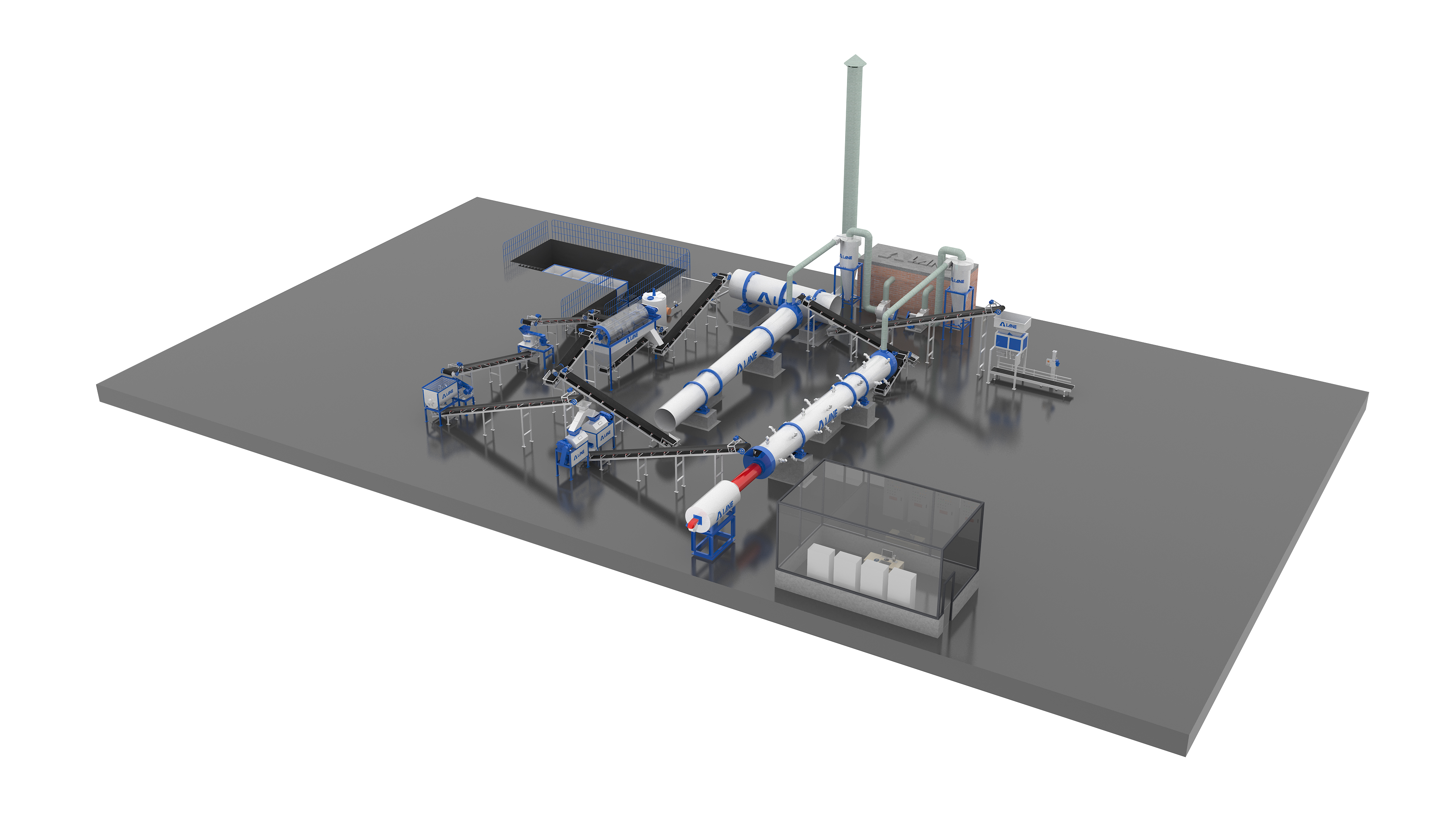

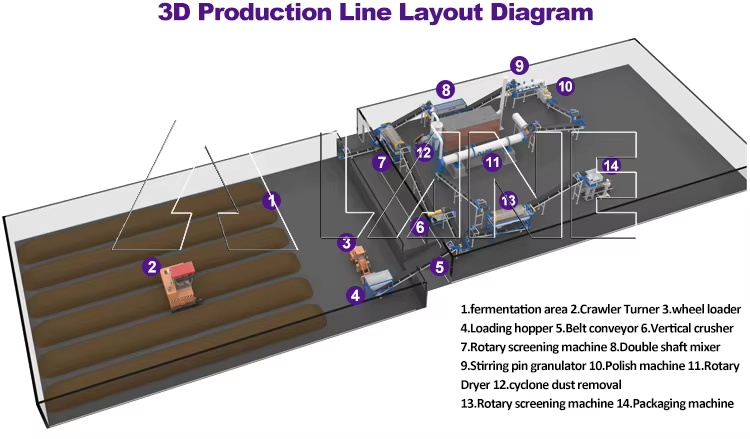

High production efficiency,1-20tons/h

Applicable materials:

Wine dregs, soy sauce dregs, vinegar dregs, furfural dregs, xylose dregs, enzyme dregs, sugar dregs, medicine dregs.

Warranty: 5 Years

Delivery Time: Within 45 days

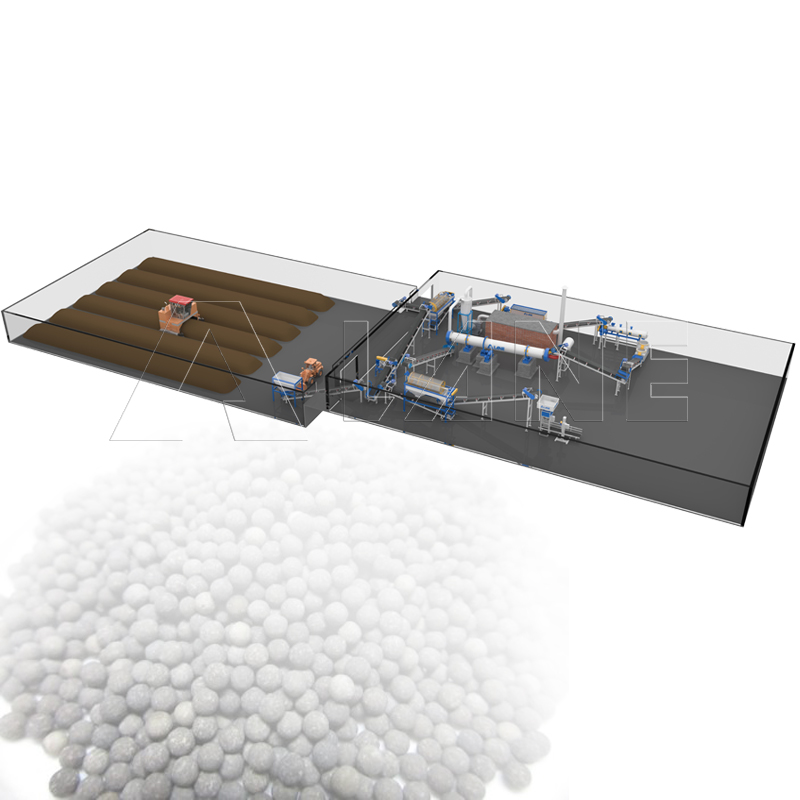

The medicine dregs organic fertilizer production line is a comprehensive treatment process that converts solid waste such as traditional Chinese medicine residue and western medicine residue into efficient organic fertilizer. Pharmaceutical residue is the residue of the production process, contains more organic substances, is a better organic fertilizer, can improve the soil structure, improve soil fertility, improve the soil microbiological environment.

LANE can customize a dedicated medicine dregs organic fertilizer production line for you to meet any of your needs.

You can click on the numbers to see detailed pictures!

How to use dregs of a decoction residue to make organic fertilizer?

1. Raw material crushing: crush the medicinal dregs produced in the production into 10-50 meshes through a pulverizer. The purpose of crushing is to avoid entanglement and stirring of the rotating blades in the fermentation tank during the process of decomposing and stirring;

2. Ingredients: Put the medicine dregs crushed in step 1, livestock and poultry manure, fermented bacteria and water into the mixer according to the ratio of 55~70:15~25:2~4:10~30 and stir evenly;

3. Fermentation with high-temperature equipment: Put the mixed materials in step 2 into a high-temperature fermentation tank, keep the temperature at 60-90°C, and ferment for 1-2 days to complete the fermentation;

4. Aging: Put the fermented materials in step 3 in an aging room, keep the temperature at 60-70°C in a ventilated state, and carry out secondary fermentation during the aging process, which lasts for 3-6 days;

5. Granulation: Put the raw materials such as the traditional Chinese medicine dregs in step 5 into a granulator after crushing again, keep the moisture content of the material at 8-15% at a temperature of 50-60°C, and granulate;

6. Drying: In the dryer, under the condition of ventilation, control the temperature at 100-120°C, dry for 20-40 minutes, and the moisture content of the material is 3-5%;

7. Cooling: put the dried material in step 7 into the cooler, and cool it to room temperature under ventilation;

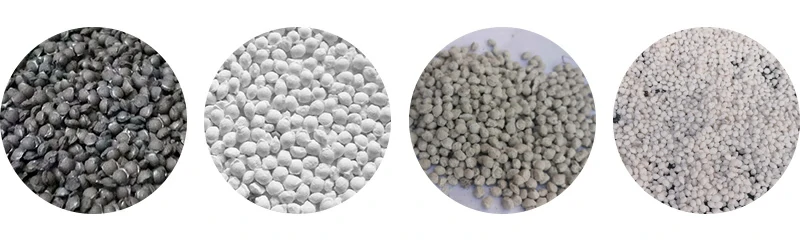

8. Finished product: the material cooled in step 8 is screened by a sieving machine, and the particle size is kept at 1-4.5 mm, and then packed.

Shown below is our medicine dregs organic fertilizer production line case, please contact us for more information.