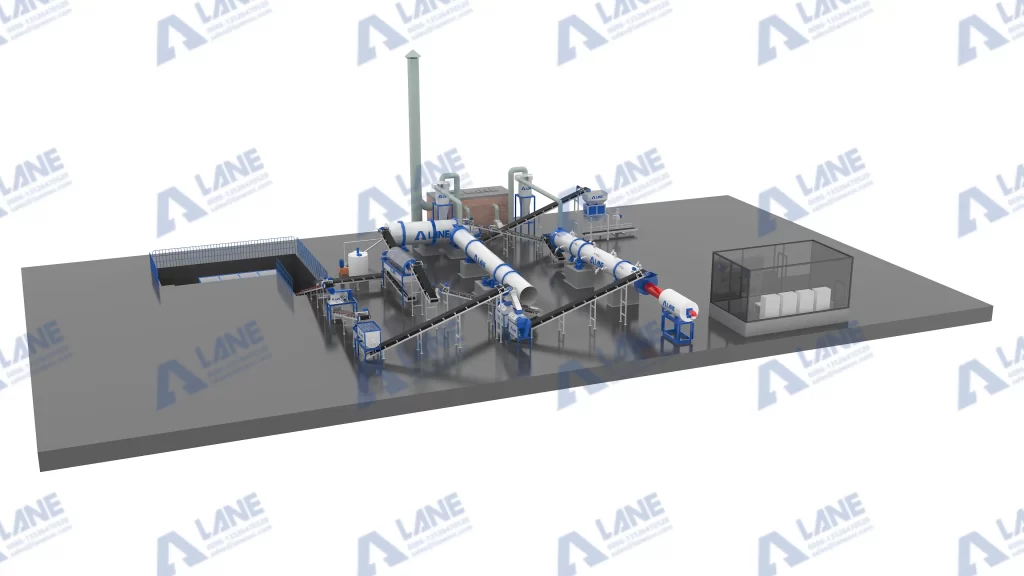

For enterprises and farmers who want to create a medium or large-scale organic fertilizer production, building a compost production line by effectively integrating Organic Fertilizer Composting Equipment is the key to unlocking efficiency and quality. A standalone compost machine can only handle a partial process. To create a synchronized, efficient production line, enterprises need to create seamless collaboration between core Organic Fertilizer Composting Equipment and supporting systems.

The goal is not just making high-quality compost, but to manufacture a consistent, high-quality, and marketable product efficiently on a large scale. A haphazard collection of machines will create bottlenecks and inconsistent results. This article explores how to integrate organic fertilizer composting equipment into a complete line with LANE’s expertise.

The journey of raw material into active composting begins right after raw materials collection. The first step is to crush, mix and adjust the collected organic material for moisture and carbon-nitrogen (C/N) ratio. The optimal ratio depends on the raw materials.

This directly affects compost efficiency and nitrogen retention rate.

The raw organic materials like animal manure, agricultural waste, and plant stalks come in various sizes and compositions. They need to be crushed for uniform composting. Smaller particles can be easily broken down which increases microbial activity and faster decomposition. LANE semi-wet crusher or wood crusher are used in this stage for crushing the raw materials.

Once crushed, the materials are conveyed to a LANE Mixer or Blender. This is where science meets scale. The mixer ensures your carbon-to-nitrogen ratio, moisture content, and other critical factors are perfectly homogenous across the entire batch.

This is the core of the operation. In this process, organic materials are turned into compost in a controlled process using high-quality Organic Fertilizer Composting Equipment. For large-scale production lines, it can be done by crawler turner or groove turner.

The blended materials are formed into long piles called windrows. LANE self-propelled hydraulic crawler turner is a workhorse equipped with a water spraying system to keep the temperature of the pile optimal and also works as a secondary crusher.

The groove-type turner, equipped with high-torque blades, stirs the material pile thoroughly every 4-6 hours, promoting oxygen circulation and heat dissipation. It’s suitable for 10-50 tons per day production line. What makes the integration seamless is that the turner’s operation is synchronized with LANE’s intelligent aeration fans.

These turners transform a 6-12 month long process into organic compost into a matter of 25-40 days. The efficiency of turners directly dictates the throughput of the entire plant. Using LANE Organic Fertilizer Composting Equipment, the turners can run continuously, ensuring the raw materials flow into the next stage smoothly.

Once composting is complete, the compost must go through the aging process. In this process composts are piled into an area. In this process all the moisture gets dried. You need to turn the pile for uniform aging.

After aging is done, the composted materials are sent to the screening machine. Compost materials contain some clumps and undecomposed fragments after coming out of aging. They are fed into a LANE Rotary Screening Machine. This equipment separates the fine, finished compost from oversized materials and impurities. The fine powder is the final product while the larger pieces are sent back to the composting process to be crushed and re-composted.

To increase the value and shelf-life of the compost, it needs to be processed into granular form. The screened powders are sent to the LANE granulator for ease of application and storage. The wet granules then pass through LANE dryer and Cooler to achieve ideal moisture content and hardness for storage. The finished granules are automatically weighed and bagged by a LANE Automatic Packaging Scale.

This stage transforms bulk compost into a granular form which is easy to package, allowing you to command a higher price in the market. Using high-quality Organic Fertilizer Composting Equipment ensures consistent granule size, optimal drying, and efficient packaging.

LANE designs and creates seamless composting solutions for small, medium, and large farms, gardens, or businesses. We offer Organic Fertilizer Composting Equipment and full turnkey service—from design to integration to training. A disjointed line from multiple suppliers creates compatibility issues and operational headaches. A unified LANE line offers:

An integrated organic fertilizer composting equipment in a large production line needs to be consistent, reliable and durable to be profitable. By partnering with an experienced manufacturer like LANE Machinery, you gain more than just machines. You gain efficiency, quality, and growth for your business. Whether you’re expanding an existing operation or building a new line, LANE’s expertise ensures that your organic fertilizer composting equipment works in perfect harmony, unlocking maximum value from organic waste.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520