Table of Contents

The organic fertilizer factory business opportunity is a compelling eco-friendly venture. As consumers demand more chemical-free produce and governments push for green farming practices, the demand for high-quality organic fertilizer continues to surge. The global interest towards sustainable agriculture has unlocked a compelling organic fertilizer factory business opportunity. For investors and entrepreneurs, establishing an organic fertilizer production plant represents a chance to build a profitable venture aligned with the principles of the circular economy. This article dives into market trends, investment requirements, profit potential, and how LANE Heavy Industry’s advanced production lines can help entrepreneurs capitalize on this organic fertilizer factory business opportunity.

The organic fertilizer market is valued at USD 10.5 billion in 2025 and might reach USD 17.9 billion by 2032, growing at a compound annual growth rate (CAGR) of 7.8% according to 24 chemical research. This steady expansion highlights a strong organic fertilizer factory business opportunity for investors seeking long-term growth in sustainable agriculture. Other analysis suggests even more dynamic growth in specific segments, such as organic natural fertilizers, which are forecast to exhibit a remarkable 22.7% CAGR from 2025 to 2032.

Several interconnected factors are fueling this organic fertilizer factory business opportunity:

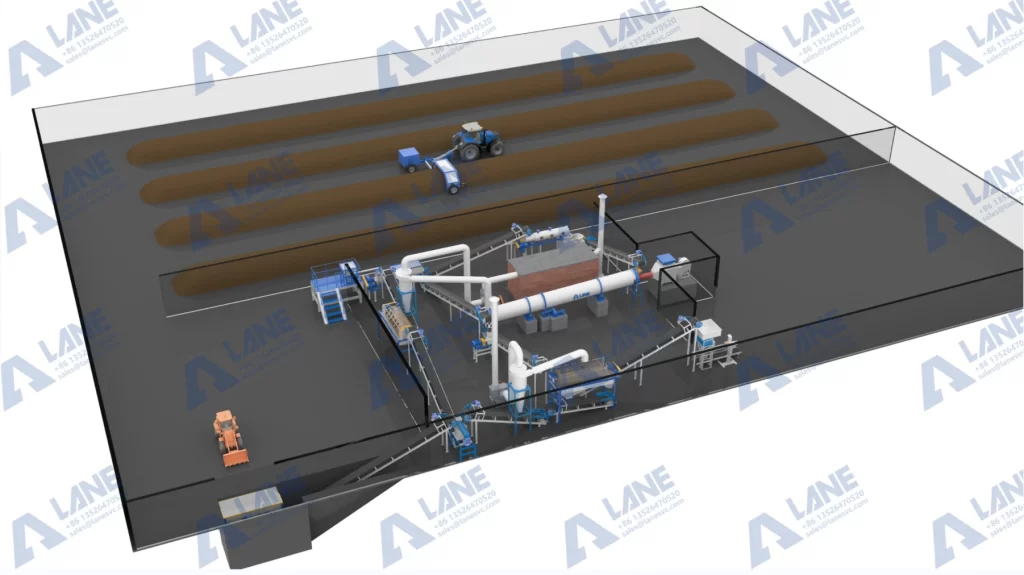

The heart of this organic fertilizer factory business opportunity is an efficient, scalable production line. A standard plant transforms raw organic waste such as animal manure, agricultural residue, and food waste into high-value, packaged fertilizer. Partnering with LANE Heavy Industry ensures access to integrated, durable equipment. An automated production line involves several key stages:

Key Machinery in the LANE Heavy Industry Line:

LANE Heavy Industry’s production line simplifies maintenance, training, and ensures process cohesion, helping businesses fully realize the organic fertilizer factory business opportunity.

A realistic financial model is crucial for evaluating the organic fertilizer factory business opportunity. Costs can be broken into capital expenditure (CAPEX) for land, factory, and machinery, and operational expenditure (OPEX).

Sample Investment Breakdown for a Mid-Scale Plant:

| Cost Component | Estimated Range | Details |

| Land & Building | $200,000 – $500,000 | Highly location-dependent. |

| Machinery & Plant Setup | $90,000 – $800,000 | Varies greatly with capacity and automation level. |

| Raw Material Inventory | $20,000 – $50,000 | Initial stockpile of manure/compost. |

| Licensing & Pre-operational | $10,000 – $30,000 | Organic certification, permits, etc.. |

| Total Initial Investment | $320,000 – $1,380,000 |

Profitability and Returns:

The revenue potential is significant. A 2024 project report for an organic fertilizer factory indicated an investment of $1.24 million could generate annual sales of approximately $1.07 million, with a net profit of $47,700 and an investment payback period of about 3.17 years.

| Financial Metric | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 |

| Annual Sales Revenue | $700,000 | $1,100,000 | $1,500,000 | $1,700,000 | $1,900,000 |

| Cost of Goods Sold (COGS) | $490,000 | $715,000 | $900,000 | $986,000 | $1,064,000 |

| Gross Profit | $210,000 | $385,000 | $600,000 | $714,000 | $836,000 |

| Operating Expenses | $180,000 | $220,000 | $260,000 | $280,000 | $300,000 |

| Net Profit (Before Tax) | $30,000 | $165,000 | $340,000 | $434,000 | $536,000 |

| Net Profit Margin | 4.3% | 15.0% | 22.7% | 25.5% | 28.2% |

Note: The above table is a simplified illustrative model based on industry data. Actual figures will vary based on plant scale, location, efficiency, and market prices.

While the organic fertilizer factory business opportunity is strong, new entrepreneurs face several challenges:

Strategic Recommendations for Success:

The organic fertilizer factory business opportunity is a perfect blend of profitability and sustainability. It is driven by market demand, government support, and eco-friendly trends. The success of the organic fertilizer factory business opportunity depends on a well-planned investment in efficient production technology, a strategic approach to market challenges, and a focus on building a reliable, quality-driven brand. With LANE Heavy Industry’s advanced production lines, entrepreneurs can overcome operational challenges and tap into this growing market efficiently.

Q1: What is the typical payback period for an organic fertilizer factory investment?

A: Based on project reports, a well-managed plant can achieve a payback period of approximately 3 to 5 years. One case study showed a payback period of 3.17 years with an internal rate of return (IRR) of 37.9%. This makes the project an attractive organic fertilizer factory business opportunity for investors seeking stable returns in the agricultural sector.

Q2: What are the main raw materials needed, and are they easy to source?

A: Primary raw materials include animal manure (poultry, cattle), agricultural waste (straw, husks), food processing waste, and municipal green waste. Sourcing is generally feasible, but establishing reliable, long-term supply contracts is crucial for consistent production and cost control. Understanding feedstock availability is essential when evaluating an organic fertilizer factory business opportunity in different regions.

Q3: Is organic fertilizer certification mandatory, and how do I get it?

A: Certification is mandatory to sell your product as “organic” to certified organic farms. The process is administered by accredited agencies (like USDA NOP or EU equivalents) and involves a detailed review of your ingredients, production process, and facility to ensure compliance with organic standards. It can take 12–18 months and requires an investment.

Q4: What is the production capacity of a standard plant?

A: Capacity varies widely. Small-scale lines can produce 1–3 tons per hour, while large, fully automatic industrial lines, such as those offered by manufacturers like LANE Heavy Industry, can have capacities exceeding 10 tons per hour. The business plan should match capacity to local market demand and feedstock availability.

Q5: How do I choose the right machinery supplier?

A: Look for a supplier with a strong track record, like LANE Heavy Industry, that can provide a complete, integrated production line (from fermentation to packaging), offer clear technical specifications, provide installation guidance, and supply reliable after-sales service and spare parts support.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520