The new type organic fertilizer granulator utilizes the high-speed rotating mechanical stirring force and the resulting aerodynamic force to continuously mix, granulate, spheroidize, and compact fine powder materials inside the machine, thereby achieving the purpose of granulation.Lane can customize a new type organic fertilizer granulator for you to meet any of your needs.

New Type Organic Fertilizer Granulator |

|||||

|---|---|---|---|---|---|

| Model | Size(mm) | Drum size(mm) | Mixing Shaft(mm) | Capacity(tph) | Power(kw) |

| LAZJ-600 | 4500*1500*1050 | Φ600*1800 | 219*10 | 1-2 | 37 |

| LAZJ-800 | 4900*1700*1250 | Φ800*2400 | 245*10 | 2-3 | 45 |

| LAZJ-1000 | 5300*1900*1400 | Φ1000*3000 | 273*10 | 3-5 | 75 |

| LAZJ-1200 | 5700*2100*1700 | Φ1200*3000 | 325*12 | 6-8 | 90 |

| LAZJ-1500 | 6200*2800*2000 | Φ1500*3000 | 325*12 | 8-10 | 110 |

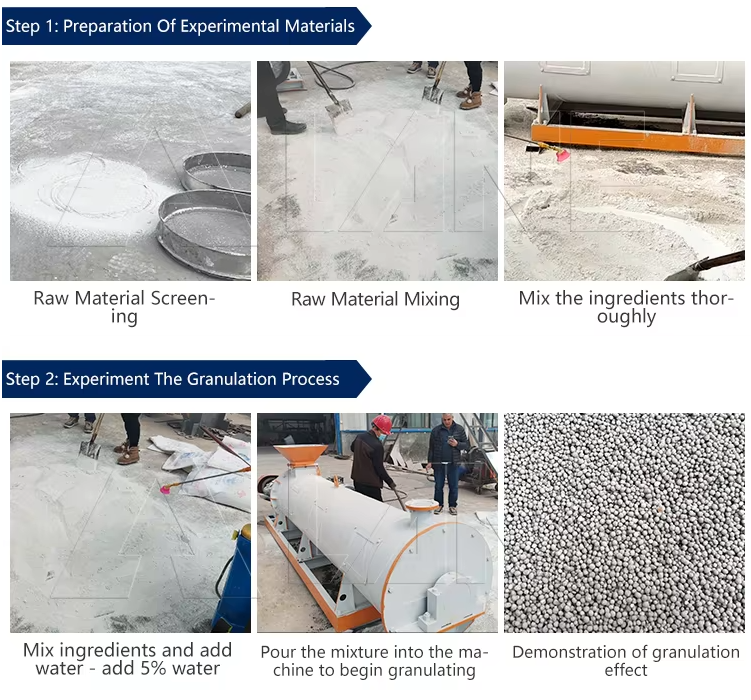

First, the organic materials to be processed are mixed and fermented.

Add an appropriate amount of water or steam to the raw materials to make the materials reach a humidity suitable for granulation. This step is crucial for the formation of particles. Appropriate humidity can promote the bonding and molding of particles.

Use mechanical devices such as spiral rotation to stir and extrude the materials. During high-speed operation, pressure is generated between the materials, and the particles gradually form and detach from the mold. At the same time, the air volume is adjusted to control oxygen supply and normal heat dissipation, so as to ensure that the equipment can operate continuously.

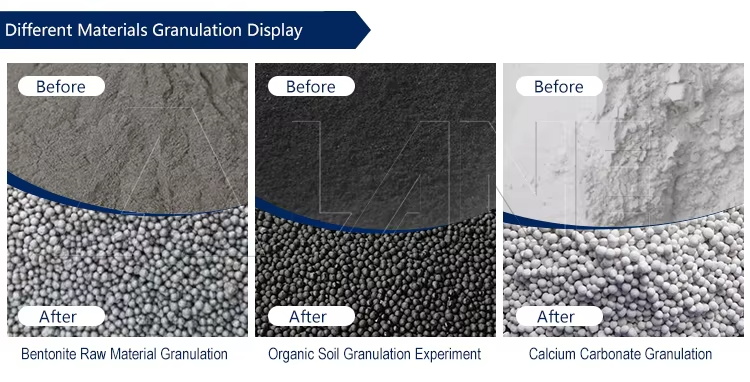

After stirring and extrusion, the materials form spherical particles. The shape and size of these particles can be appropriately adjusted by adjusting the equipment. Generally, the lower the mixing amount and the higher the speed, the smaller the particles formed; conversely, the larger the particles.

The newly formed particles need to be cooled before being collected and packaged.

If you have a better idea, or would like to do an experimental test as well, please contact us right away!

Easy to operate and maintain

The simple and easy-to-understand design fully considers the convenience of users, making it easy for operators to quickly get started and regularly check and maintain, ensuring long-term and stable operation of the equipment.

High output

The design of the new organic fertilizer granulator focuses on production efficiency. It can process a large amount of organic matter in a short time and form uniform particles, greatly improving production efficiency and output.

High granulation rate

Advanced granulation technology is used to ensure a high granulation rate of organic materials, reduce material waste, and improve granule quality.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.