Potassium is a vital nutrient for crop growth. It directly influences stress resistance and yield quality of the crops. Creating a balanced, effective, and certifiable fertilizer is a complex task. Many organic fertilizer producers focus on nitrogen and phosphorus while not paying much attention to potassium.

Organic fertilizer potassium is a silent powerhouse crucial for plant vigor, disease resistance, and overall yield. Sourcing and processing this nutrient in an efficient and consistent manner is one of the biggest challenges in modern fertilizer manufacturing.

This is where specialized industrial expertise and technology become critical partners. This article explores the sourcing of potassium inputs and scientific processing approaches in organic fertilizer production.

Conventional agriculture relies heavily on mined muriate of potash (MOP). However, for OMRI-listed or similarly certified organic fertilizers, MOP is prohibited due to its high solubility and synthetic processing. Manufacturers must use natural raw materials as alternatives. The raw materials for organic fertilizer potassium include:

Langbeinite: This is a naturally occurring mineral containing potassium, magnesium, and sulfur. It is prized for providing soluble, but not overly leachable, potassium, along with vital magnesium and sulfur.

Granite Meal: This is one of the common sources of potassium. It releases potassium very slowly over years through weathering.

Kelp Meal: This is a sustainable source of potassium derived from seaweed. It offers potassium along with trace minerals and growth hormones.

Wood Ash: This is a variable source with high pH levels. This makes it challenging for large-scale, consistent formulation.

The central dilemma of sourcing is finding a consistent supply of these raw materials. Securing a reliable supply of consistent quality and ensuring they are processed to organic standards is what makes a great organic fertilizer.

Raw potassium inputs like langbeinite or granite dust are not suitable for direct mixing. They require processing to be effective in a commercial organic fertilizer potassium blend.

Size Reduction: Materials must be crushed into a fine powder before they can be used as raw material for the fertilizer. There are two reasons for doing this. One is to increase the surface area for nutrient availability, and the other is to ensure uniform blending with other materials like composted manure or bone meal. Inconsistent particle size leads to uneven nutrition distribution in the fertilizer.

Drying or Composting: Many natural inputs, especially kelp meal or certain mineral ores, can have high moisture content. This high moisture can lead to clumping, microbial spoilage, and difficulties in the granulation process. Drying or composting is needed for many heat-sensitive materials.

Granulation: For ease of handling and application, most commercial organic fertilizers are pelletized. Incorporating dense, mineral-based organic fertilizer potassium sources into a uniform pellet requires specialized granulators with the right balance of pressure, temperature, and sometimes organic binders to create a durable, dust-free product that breaks down predictably in the soil.

This is where partnering with an expert industrial equipment provider like LANE Heavy Industry becomes an advantage. A generic equipment line cannot handle the abrasive nature of rock minerals or the precise requirements of organic compliance. LANE Heavy Industry provides tailored solutions needed to transform potassium sources into a premium product.

Heavy-Duty Crushing and Grinding Mills: LANE’s crushing equipment is engineered to process hard, abrasive materials like granite dust and langbeinite to required mesh specifications. LANE’s hammer crusher is efficient and maintains minimal wear, ensuring consistent particle size batch after batch.

Precision Drying Systems: LANE’s rotary dryer and cooler offer controlled, indirect heating solutions that can reduce moisture in kelp or mineral inputs without compromising their organic integrity through overheating.

Advanced Granulation Technology: The core of the production line is the granulation machine. LANE Heavy Industry provides organic fertilizer-specific granulation systems. LANE’s stirring pin granulator can handle a mix of organic and mineral materials. Our expertise ensures the organic fertilizer potassium is evenly distributed.

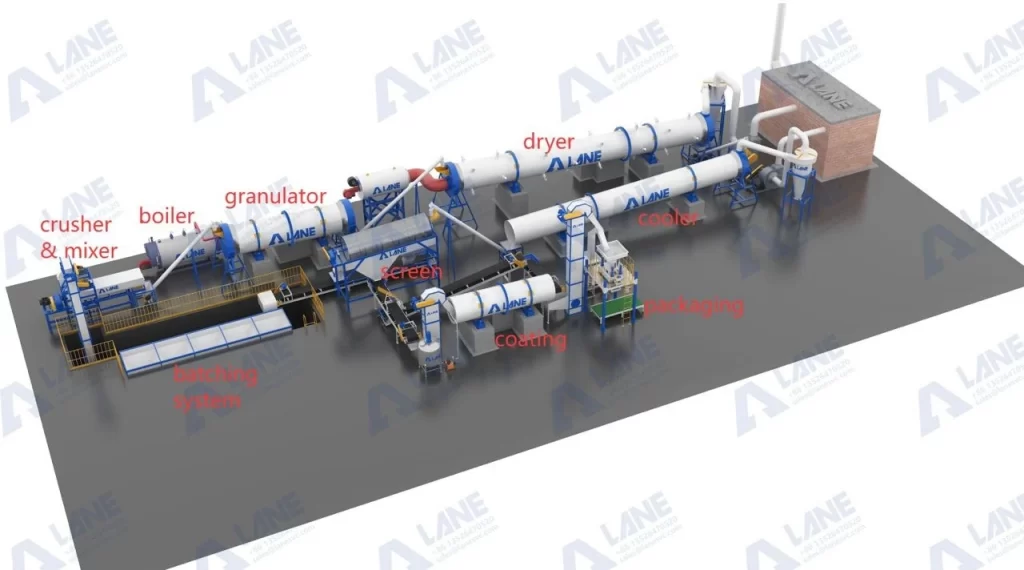

Integrated System Design: The most valuable advantage of the production line is LANE’s ability to design and integrate a complete processing line. From raw material processing to moving them through conveyors to final screening and packaging, a seamlessly integrated system maximizes throughput, minimizes labor, and ensures a consistent, high-quality final product.

Manufacturing organic fertilizer potassium is more than just adding a raw material to the compost pile. It represents a chain of decisions, from selecting the right raw material to creating a proper compost blend or direct raw material mix and integrating it into a homogeneous, marketable product.

Sustainable organic fertilizer potassium production is essential for modern agriculture. By taking advantage of LANE’s advanced systems and diverse raw materials, organic fertilizer producers can transform this fundamental challenge into a core competitive strength. The result is a reliable, high-quality organic fertilizer potassium fertilizer which sells for a premium price.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520