Governments all over the world giving incentives towards sustainable agriculture and organic farming. It is creating an unprecedented demand for high-quality organic fertilizers. organic fertilizers have become a cornerstone of eco-friendly farming. It is slowly replacing chemical alternatives to improve soil health and crop quality. Learning how to start an organic fertilizer production business is the first step towards tapping into this green economy.

Starting an organic fertilizer production business is a strategic venture that aligns with global trends toward sustainable agriculture and circular economics. By transforming organic waste into valuable nutrients for plants, entrepreneurs can tap into a growing market while addressing environmental concerns.

A solid business plan is the foundation of a successful business. Government policies around the world are helping the organic market expand. The governments want less chemical fertilizer in the field to protect soil and promote sustainable farming practices. Your complete business plan should define your business scope, target market (e.g., specialty crop farms, organic orchards, home gardeners), and analyze local competitors.

Your business plan should define your target scope, market (e.g., specialty crop farms, organic orchards, home gardeners), and counterplan for your local competitors. But most importantly, you must identify a consistent and cost-effective source of raw materials. Common inputs include animal manure, agricultural waste, food processing by-products, and municipal green waste. Securing a reliable supply agreement with local farms or processing plants is a crucial first step of learning how to start an organic fertilizer production business.

Formally starting your business is a multi-step process. You must first register your company. This includes a fertilizer production assessment. Key administrative steps include:

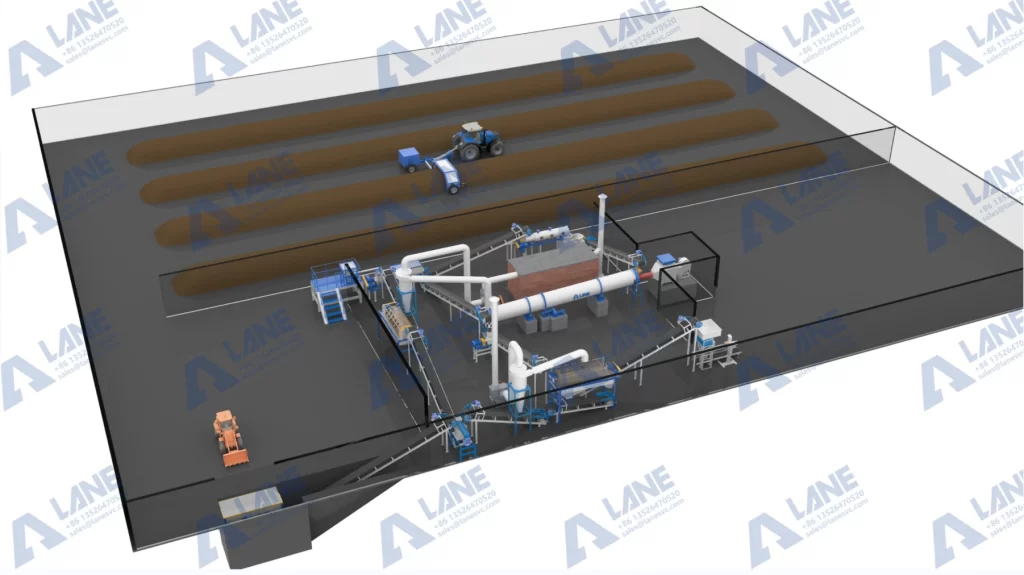

Location is critical for logistics and cost management. For anyone starting an Organic Fertilizer Production Business, ideal sites are close to both raw material sources (e.g., large livestock farms) and target markets to minimize transportation costs. A basic facility for a small-scale operation should be at least divided into functional zones:

Proper zoning ensures an efficient workflow, a key consideration for anyone planning how to start an organic fertilizer production business.

The production line is the heart of your operation. For any Organic Fertilizer Production Business, reliable, efficient equipment from LANE Heavy Industry can dictate your long-term productivity and product quality. A full production line is a coordinated system of machines.

LANE Heavy Industry provides after-sales service, a 5-year warranty, and always has spare parts available. We fully help you maintain your new organic fertilizer production business.

Understanding the production flow is important to know how to start an organic fertilizer production business.

While you are creating your production line, you should also create your brand. Register a trademark and design informative packaging that highlights the benefits of your product. Provide details like improved soil structure and long-term nutrition. Marketing channels can include direct sales to farms, partnerships with agricultural cooperatives, and online stores. To gain a competitive edge and justify a premium price, obtain organic certification for your fertilizer from a recognized national body. This officially validates your process and ingredients for discerning customers.

Initial investment varies greatly with scale. A small factory with an annual output of 5,000 tons may require equipment investment of approximately 125,000 USD to 200,000 USD. This is a crucial part of your research on how to start an organic fertilizer production business. Key cost factors include:

Explore government subsidies for agricultural waste resource utilization. These subsidies can greatly improve your project’s financial viability.

Q: How much does it cost to start a small organic fertilizer plant?

A: For entrepreneurs entering the Organic Fertilizer Production Business, a small-scale plant with an annual capacity of around 5,000 tons typically requires an initial investment ranging from 800,000 to 1.5 million RMB. This mainly includes land, factory construction, and core production line equipment. The cost of a specific LANE Heavy Industry production line will account for a major portion of the budget and varies depending on automation level and designed capacity.

Q: What is the key difference between organic and chemical fertilizers?

A: The core difference lies in long-term soil impact. Organic fertilizers are derived from natural raw materials and contain organic matter that improves soil structure, enhances water retention, and promotes beneficial microbial activity—key advantages for anyone planning a sustainable Organic Fertilizer Production Business. In contrast, chemical fertilizers provide fast-acting nutrients but do not improve soil health and may lead to soil degradation with prolonged use.

Q: What is the most important piece of equipment for an organic fertilizer business?

A: While each machine in the production line plays a role, the fermentation system is the foundation. Efficient fermentation—achieved through well-designed compost turners or fermentation tanks—directly affects production speed, pathogen elimination, and final product quality. This stage is especially critical to the long-term success and profitability of an Organic Fertilizer Production Business, and is a core strength of LANE Heavy Industry’s complete production solutions.

Q: Do I need special permits to sell organic fertilizer?

A: Yes. After setting up your company and beginning production, you must apply for and obtain a Fertilizer Registration Certificate from the agricultural authorities in your province. Your product must pass lab tests to confirm it meets national standards before this certificate is issued.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520