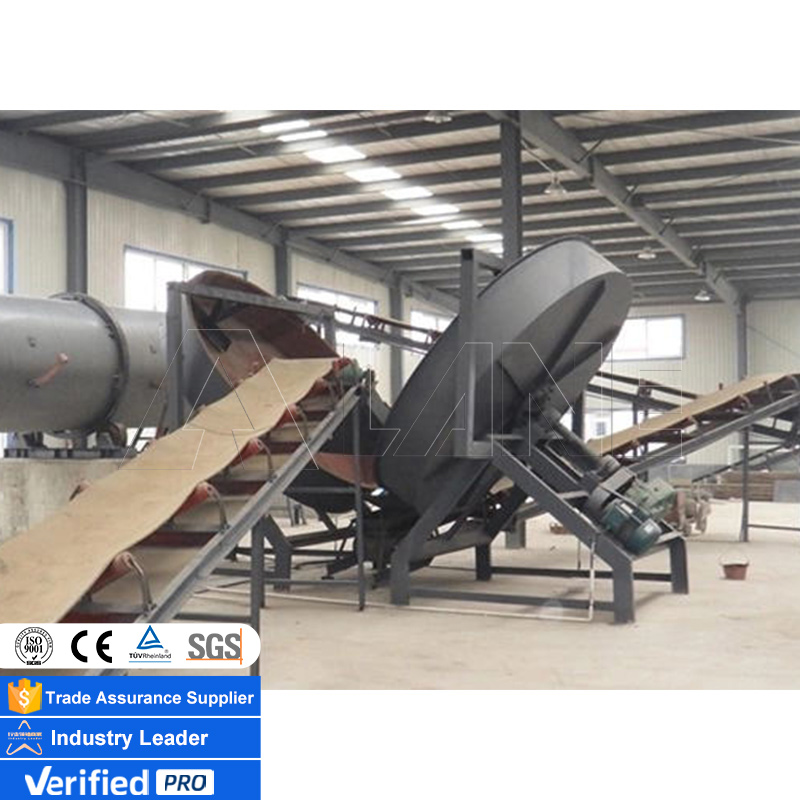

Brand: LANE

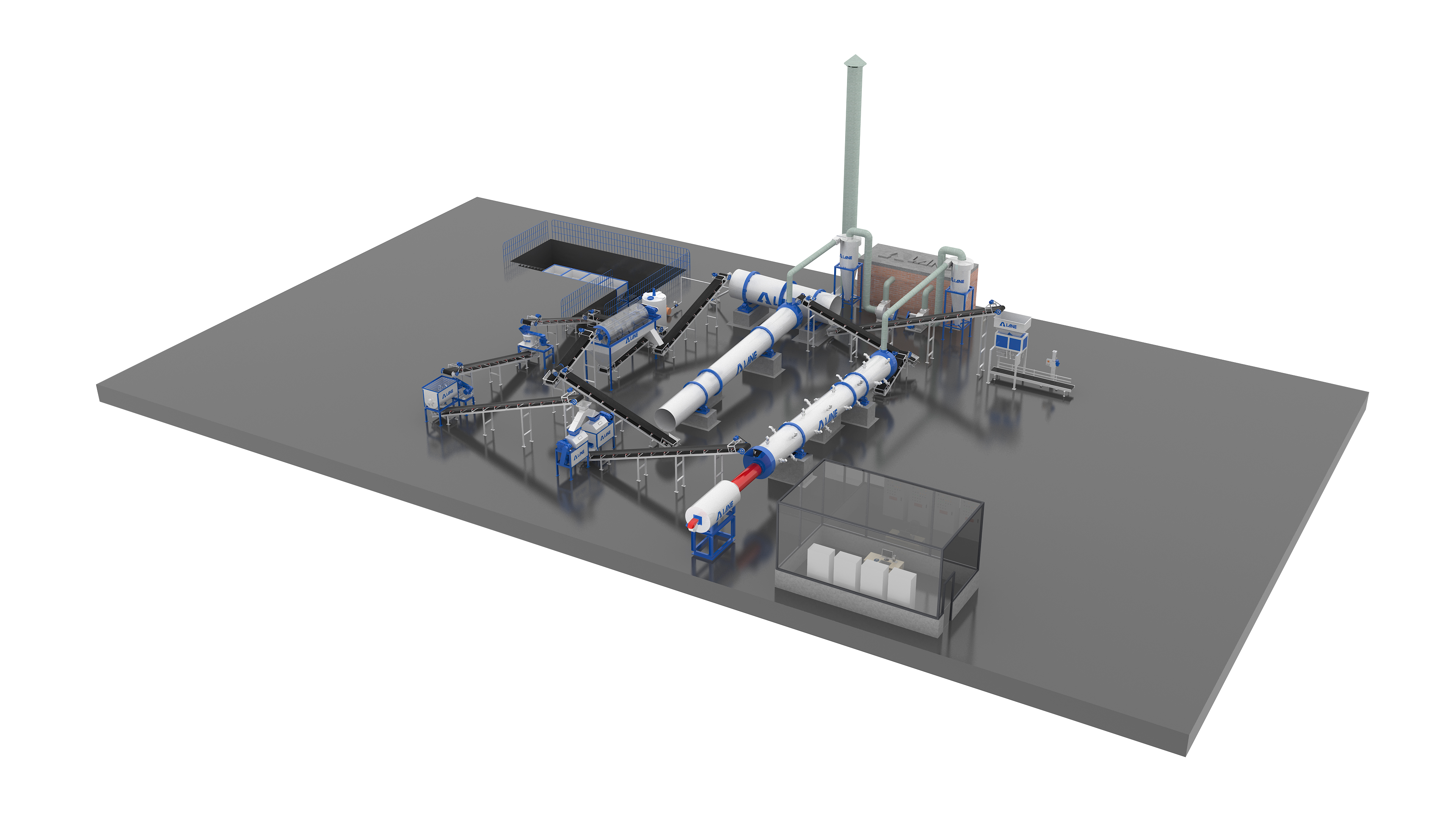

Production line advantages:

Compact structure, well-designed craftsmanship, easy installation, simple operation, low maintenance costs, and minimal investment.

Applicable materials:

Crop straw, animal excrement, domestic waste, etc.

Warranty: 5 Years

Delivery Time: Within 45 days

The organic fertilizer production line is a complete set of equipment and processes that convert organic waste such as livestock manure, crop straw, etc. into efficient organic fertilizers.LANE can provide you with professional organic fertilizer production line services and help you solve all problems.For more information about the organic fertilizer production line, please contact us by sending an inquiry today! We can help you!

You can click on the numbers to see detailed pictures!

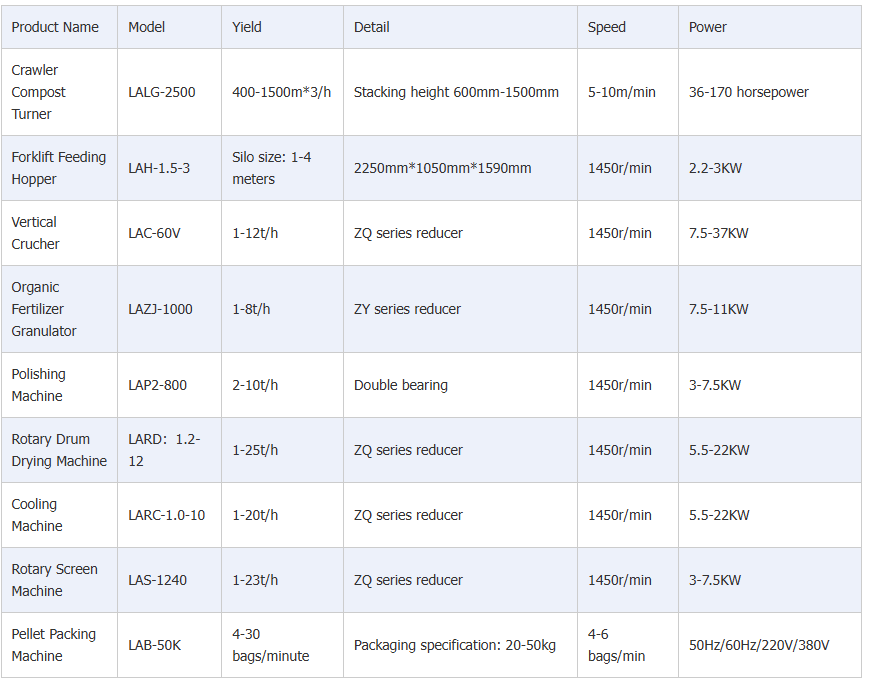

The following are the product parameters used in the production line:

Raw material processing equipment

Dryer: used to reduce the moisture content of the raw material to a level suitable for fermentation.

Crushing equipment: such as vertical crusher, horizontal crusher, etc., used to crush the raw material to a suitable particle size.

Mixing equipment: such as horizontal mixer, double-shaft mixer, etc., used to mix the raw material, strain and auxiliary materials evenly.

Fermentation equipment

Turning machine: including trough turning machine, crawler turning machine, etc., used to turn the raw material during compost fermentation, increase the oxygen content in the pile, and control the fermentation temperature.

High-temperature aerobic fermentation tank: small footprint, high degree of automation, no secondary pollution, suitable for areas with strict environmental protection requirements.

Deep processing equipment (optional)

Mixer: used to add other nutrients to the fermented raw materials to improve the indicators of biological organic fertilizer.

Granulation, drying and cooling equipment: such as disc granulator, flat die extrusion granulator, drum dryer, drum cooler, etc., are used to process powdered organic fertilizer into granules to improve product appearance and market competitiveness.

Packaging and transportation equipment

Conveying equipment: such as belt conveyor, bucket elevator, screw conveyor, etc., are used to automatically transport production raw materials to the next link.

Automatic quantitative packaging machine: used to pack finished organic fertilizer, and can perform various types of automatic unloading and packaging operations according to needs.

In summary, there are many types of equipment in the organic fertilizer production line, and each equipment has its specific purpose and function. From raw material processing to final packaging and transportation, each link requires corresponding equipment to complete. These equipment not only improves production efficiency, but also ensures the quality and environmental performance of organic fertilizer.

Finished product samples: