Tapping into Demand: Why an Organic Fertilizer Production Line in Belarus is a Smart Investment

Table of Contents

- Introduction: Belarus’s Agricultural Shift

- Market Drivers: The Forces Fueling Demand

- The Investment Rationale: Economic and Strategic Benefits

- LANE Heavy Industry: The Robust Machinery for Belarusian Success

- From Raw Material to Market: The Production Process

- Conclusion: Seeding a Sustainable Future

- Frequently Asked Questions (FAQ)

Introduction: Belarus’s Agricultural Shift

Belarus, with its vast agricultural lands and strong farming tradition, boasts a thriving agricultural sector that serves as the backbone of its economy. Its agriculture sector accounts for 8% of its GDP. With the increased global and domestic focus on sustainable agriculture, the demand for organic fertilizer is surging. This has created an opportunity for investors looking to tap into a high-potential market: an organic fertilizer production line in Belarus.

Organic fertilizers are created from natural waste materials like animal manure, crop straw, and food waste. They are becoming indispensable for Belarusian farmers aiming to improve soil quality, boost crop yields, and meet international organic certification standards. Establishing a modern organic fertilizer production line in Belarus is a strategic move that aligns with national priorities and powerful market trends. However, producing premium-quality organic fertilizer requires an efficient and durable production line that can create consistent, premium-quality organic fertilizer. Investing in a reliable production line engineered by LANE Heavy Industry positions entrepreneurs at the forefront of a green revolution in the heart of Eastern Europe.

Market Drivers: The Forces Fueling Demand

Several key factors are creating an opportunity for entrepreneurs to invest in an organic fertilizer production line in Belarus:

- Government Policy & Import Substitution:The Belarusian government actively promotes agricultural modernization and self-sufficiency. Reducing reliance on imported chemical fertilizers is a strategic goal, creating a supportive environment for domestic producers. Establishing an organic fertilizer production line in Belarus directly contributes to this national agenda.

- Growth of Organic Farming:The organic produce sector in Belarus is a key export market. Belarus exports organically produced crops to the EU and Russia. These organic farms require certified, high-quality organic fertilizers. This creates a dedicated and growing customer segment.

- Environmental Regulations:Belarus has stricter controls on waste management, particularly from livestock farms and food processing plants. Turning this organic waste from a disposal problem into a valuable resource is a huge economic opportunity. A production line provides the solution for compliant, profitable recycling.

- Cost Efficiency for Conventional Farms:To increase profitability, farms are searching for ways to reduce input costs and improve soil health. High-quality organic fertilizers offer a way to partially replace expensive mineral imports, ensuring strong market breadth.

The Investment Rationale: Economic and Strategic Benefits

Establishing an organic fertilizer production line in Belarus offers compelling advantages:

- Abundant Raw Materials:Belarus has a wealth of raw materials like livestock manure, poultry litter, crop residues, and peat. This local availability ensures low-cost feedstocks and stable supply chains. This is a fundamental advantage for production.

- High Value Output:This production line transforms low-value or problematic waste into a commercial product with high market value. This model ensures strong profit margins and a rapid return on investment.

- Diversification & Resilience:For existing agribusinesses like large farms and distilleries, adding a fertilizer production line diversifies revenue streams and adds resilience by monetizing waste streams.

- Export Potential:Producing standardized, premium organic fertilizer opens doors to neighboring markets with high demand. This will turn your locally based fertilizer operation into a regionally based one.

LANE Heavy Industry: The Robust Machinery for Belarusian Success

To capitalize on this opportunity, the choice of equipment is critical. LANE Heavy Industry provides high-capacity machinery perfectly suited for the scale and demands of the Belarusian market. A complete organic fertilizer production line from LANE typically includes:

- Fermentation Equipment:Efficient compost turners for aerobic fermentation are crucial for pathogen elimination and stability of the compost. A modern compost turner or fermentation tank reduces fermentation time from months to weeks.

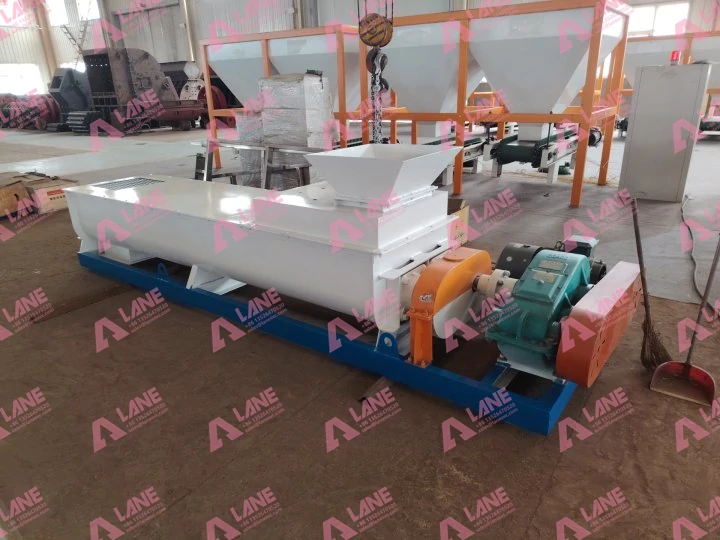

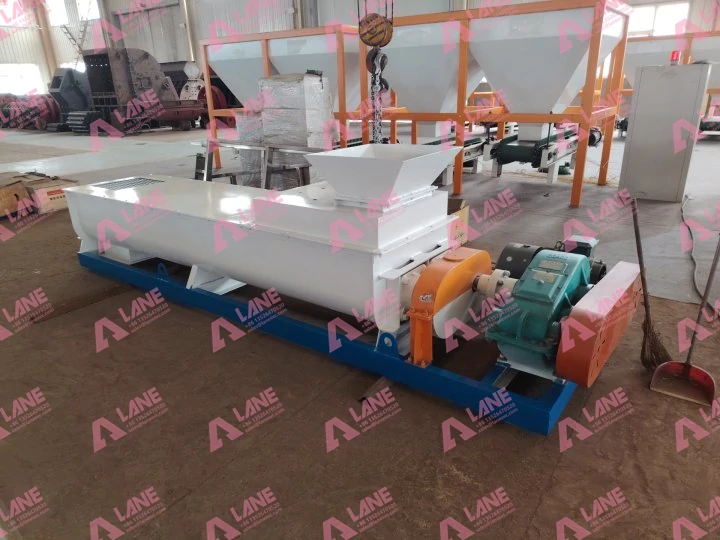

- Crushing & Mixing:A LANE crusher effectively pulverizes the compost into fine powder and sends it to the mixer where other raw materials and minerals can be added to create your custom formulation.

- Granulation Systems:This is the core of the granulation line. LANE’s organic fertilizer granulators (like disc or Stirring Pin granulators) transform powdered compost into uniform, dust-free, easy-to-apply granules.

- Drying & Cooling:After granulation, the granules are wet. Rotary dryers and coolers solidify the granules and prepare them for packaging.

- Screening:A screening machine separates on-size granules from fines and oversized granules and sends them to the crusher to re-enter the production.

- Coating & Packaging:Automated systems for coating granules to reduce caking and for weighing and bagging the final product.

LANE’s equipment is known for durability, automation, and energy efficiency. Our production line reduces labor costs and maximizes uptime.

From Raw Material to Market: The Production Process

A modern organic fertilizer production line in Belarus follows a systematic process:

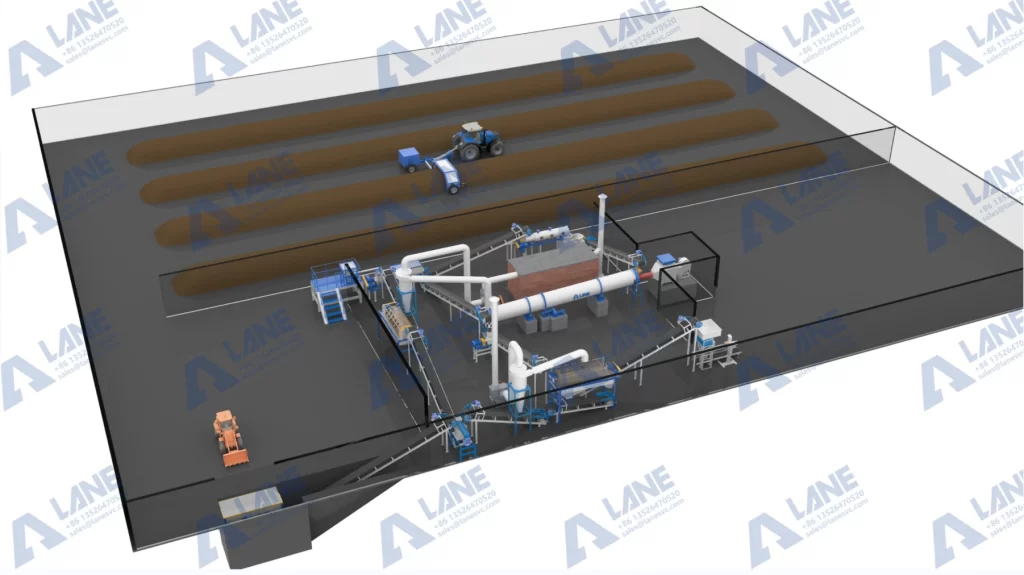

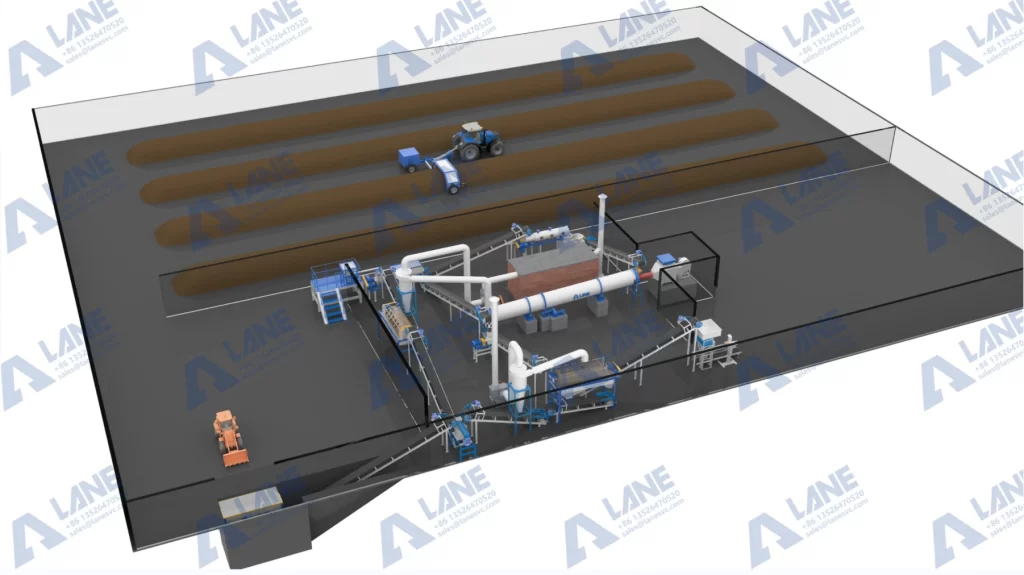

- Pre-processing & Fermentation: Raw materials are first mixed into a 25:1 to 30:1 carbon-to-nitrogen ratio and placed in long rows called windrows for aerobic fermentation. LANE deploys compost turners for fast and effective aerobic formation.

- Crushing & Blending: The composted material is crushed and blended with additives (e.g., minerals for nutrient balancing) to create a uniform powder.

- Granulation: The mixed compost is fed into the granulator, where under mechanical action and moisture, it forms dense, spherical granules.

- Drying & Cooling: Granules are dried to reduce moisture and then cooled to strengthen them.

- Screening & Packaging: Oversized and undersized granules are screened out and recycled. The on-spec product is coated and packaged for sale.

Conclusion: Seeding a Sustainable Future

Belarus’s agricultural renaissance, combined with growing global demand for organic products, has created a golden opportunity for investors. Investing in an organic fertilizer production line in Belarus is a decision that marries economic gain with environmental stewardship. With abundant raw materials, favorable government policies, excellent infrastructure, and a trusted partner like LANE Heavy Industry, investing in an organic fertilizer production line in Belarus is a decision that promises steady profitability, sustainability, and long-term growth. LANE Heavy Industry’s tailored machinery, reliable service, and customizable solutions ensure that every investor can launch and operate a successful organic fertilizer production line in Belarus, regardless of their scale or budget.

Frequently Asked Questions (FAQ)

Q1: What is the typical investment range for setting up an organic fertilizer production line in Belarus?

A: The investment varies significantly based on capacity and automation level. A small to medium-scale organic fertilizer production line in Belarus can start from approximately $150,000 for basic equipment, with larger, fully automated lines reaching $500,000 or more. LANE Heavy Industry can provide tailored solutions and quotations based on specific output goals.

Q2: Are there government incentives for starting such a project in Belarus?

A: Yes. The Belarusian government often supports projects that advance import substitution, agricultural modernization, and environmental technology. It is advisable to consult with local agricultural ministries and investment agencies about potential tax benefits, subsidies, or grants for establishing an organic fertilizer production line.

Q3: How does LANE Heavy Industry support its clients in Belarus?

A: LANE provides comprehensive support, including project design, layout planning, machinery supply, installation guidance, operational training, and after-sales technical support. They understand the requirements for establishing a successful organic fertilizer production line in Belarus and offer solutions accordingly.

Q4: What raw materials are most accessible for this business in Belarus?

A: The most common and accessible materials include cow and pig manure from large farms, poultry litter, peat (which Belarus has in abundance), and crop straw. A well-designed organic fertilizer production line can process various combinations of these locally sourced inputs.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520