Canada’s agricultural sector is getting more interested in sustainable agriculture. This boom is driven by consumer preferences and regulatory support for eco-friendly farming practices. The focus is on eco-friendly farming practices that protect soil health and reduce environmental impact. An organic fertilizer production line in Canada represents a strategic investment that contributes to soil health and captures the growing organic market opportunities.

Creating premium organic fertilizer requires efficient and durable machines that can handle the raw material without any problems. An organic fertilizer production line converts agricultural waste, livestock manure, and organic residues into nutrient-rich fertilizers. LANE Heavy Industry Machinery, a trusted manufacturer, specializes in customizable organic fertilizer production lines tailored to Canada’s unique agricultural needs. The organic fertilizer production line in Canada is no longer a niche investment but a strategic asset for farmers, agricultural businesses, and environmental organizations.

Canada’s agricultural sector is embracing organic farming and regenerative practices. This interest is driven by:

As a result, investing in an organic fertilizer production line in Canada enables producers to tap into a growing market. This investment not only brings profit to the investor but also protects the environment.

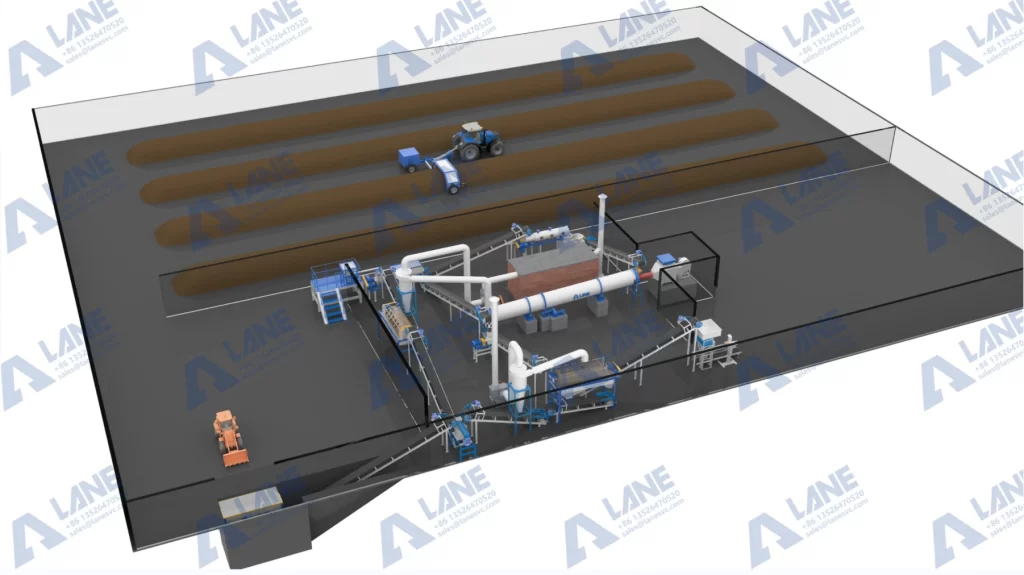

LANE Heavy Industry offers customized production line solutions that are engineered to meet customer requirements. We focus on raw materials, scale, and environmental protection while we design the production line. From small farms to large industrial plants, a complete organic fertilizer production line in Canada using LANE machinery includes:

LANE’s production lines are created with integrated design, automation capabilities, and adaptability to various organic waste types including manure, crop residues, green waste, and other biomass.

Establishing an organic fertilizer production line in Canada requires advanced technology to ensure efficiency and product quality. LANE’s production line incorporates the following:

LANE uses efficient compost turners like crawler compost turners or groove compost turners to reduce composting time and enhance microbial activity. Alternatively, LANE can also manufacture and provide aerobic fermentation tanks which can be fully controlled and convert raw organic waste into stable and pathogen-free material.

LANE employs horizontal mixers to ensure uniform mixing. For organic fertilizer, LANE employs disc, stirring pin, or rotary drum granulators for modern agricultural applicators.

LANE employs fully automated PLC/SCADA automation systems that control processing parameters, increase throughput, and reduce labor costs.

LANE fermentation tanks have odor management systems and the organic fertilizer production line employs dust control in every part of the production line. This is very important for Canadian regions with strict air quality regulations.

The cost to build an organic fertilizer production line in Canada varies significantly based on scale, automation level, and machine quality. According to industry estimates, the breakdown can include:

| Production Scale | Estimated Cost (USD) |

| Small (1–5 t/h) | $100,000–$150,000 |

| Medium (5–10 t/h) | $150,000–$350,000 |

| Large (10–20 t/h) | $350,000–$550,000 |

Key cost components include:

Note: Actual costs in Canada may differ due to local labor, shipping, installation costs, and compliance requirements.

Choosing a turnkey organic fertilizer production line in Canada from LANE Heavy Industry provides several advantages:

The opportunities for organic fertilizers in Canada are promising:

Investing in an organic fertilizer production line in Canada positions producers to benefit from both domestic and international market growth.

Q1: What is the minimum space needed for an organic fertilizer production line?

A: Space requirements vary with capacity, but medium lines often need several thousand square feet for fermentation, processing, and storage.

Q2: Can LANE machinery handle different raw materials?

A: Yes — LANE systems are engineered to process a wide range of organic feedstocks including manure, crop residues, and green waste.

Q3: How long does it take to install a production line?

A: Installation timelines depend on plant size and customization but typically range from 3–8 months for turnkey lines.

Q4: Is automation worth the investment?

A: For larger operations, automation significantly reduces labor costs and ensures consistent fertilizer quality.

Q5: Do organic fertilizer production lines require specialized skills?

A: Basic training is required, but modern systems often include user-friendly controls and manufacturer training support.

The organic fertilizer production line in Canada is a key driver of the country’s sustainable agricultural transformation, offering economic opportunities, environmental benefits, and support for organic farming growth. Setting up an organic fertilizer production line in Canada is a strategic move for businesses aiming to capitalize on the growing sustainable agriculture market. With advanced machinery and turnkey solutions from providers like LANE Heavy Industry, producers can benefit from efficient technology, scalable designs, and compliance support.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520