Nepal’s agricultural sector is the backbone of its economy. Over 60% of the national population depends on this sector, and it contributes more than 25% to the national GDP. Today, however, it faces dual challenges: declining soil fertility caused by long-term reliance on chemical fertilizers and the mismanagement of organic waste generated from farms, livestock, and households.

For decades, Nepalese agriculture has relied heavily on chemical fertilizers, leading to soil degradation, water pollution, and rising import costs. But with increasing awareness of sustainable farming practices and a steady supply of raw materials, entrepreneurs are now seeing a major opportunity. For many, building an Organic Fertilizer Production Line in Nepal has become an attractive and viable investment, helping convert organic waste into high-quality fertilizer while supporting national sustainability goals.

This is not only a business venture that generates profit; it also strengthens food security and environmental health. With the right equipment and proper technical guidance, establishing an Organic Fertilizer Production Line in Nepal can turn agricultural waste into valuable “black gold,” making it both an achievable and profitable pathway for the country’s future.

Nepal has a huge farming industry which also produces lots of agricultural wastes and also needs lots of fertilizer, which presents a compelling opportunity for those planning to build an Organic Fertilizer Production Line in Nepal.

Starting a business from scratch can feel overwhelming. A trusted partner can solve this problem. LANE heavy machinery provides customers with production design, production plans, manufactures machinery, helps build the production line, and trains the workers — all of which are especially valuable for anyone planning an Organic Fertilizer Production Line in Nepal.

Here’s a small guide for someone who is starting new.

Sourcing Raw Materials: Your first task is to secure a consistent supply of raw materials. Building a good relation with local dairy farms, poultry farmers, and vegetable markets committee is a great start. A small-scale setup can efficiently process 1-2 tons of raw material per hour. A good mix of nitrogen rich raw materials like manures and carbon rich raw materials like straw, sawdust is key to quality compost.

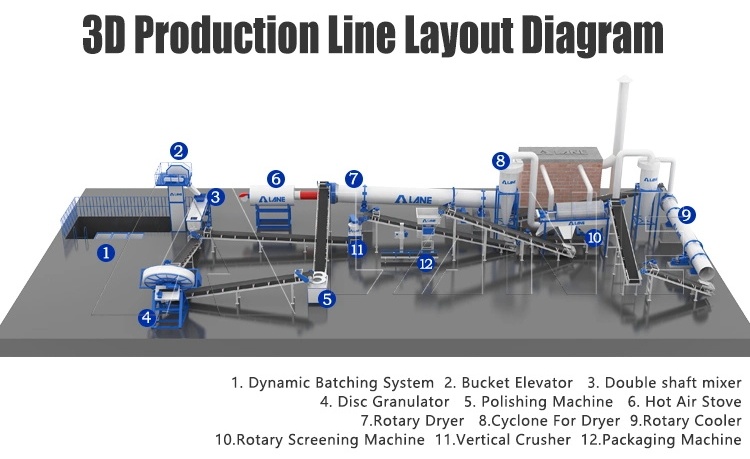

The Production Process & Essential Machinery: While composting can be done manually, it is slow, unstable, inconsistent and not suitable for industrial use. You need efficiency for your industrial process. Partnering with a reliable equipment provider like LANE Machinery can transform your operation. A basic, semi-automatic organic fertilizer production line in Nepal for a small-scale business would include

Compost Turner: This is the first and most crucial step of the process. LANE’s hydraulic crawler compost turner can efficiently mix and aerate the compost piles. It reduces composting time from 6 -12 months to 30-60 days. After the composting is done the raw materials will look like black clumps with no odor.

Feeding into the production: After crushing all the raw materials are sent to the Dynamic batching system. where it acts as a weighting machine and sends the materials to the crusher.

Crusher/Grinder: After fermentation, the compost may form clumps. LANE vertical crusher is used in this stage to crush the material into a fine powder, which is essential for creating a uniform product and for the next stage: granulation

Stirring pin Granulator: This machine is what turns your fine powder into easy-to-handle pellets. Granulated fertilizer is less dusty, easier to store and transport. It is often preferred by farmers as it provides a slow-release effect.

Rounding machine: After granulation some granules have deformities. The rounding machine uses rotation to make them rounder.

Drying and cooling: The freshly granulated fertilizer needs to be dried to reduce moisture content, preventing caking and spoilage during storage. Simple solar dryers can be sufficient for a small start. But for a more professional setup LANE provides rotary dryer and cooler.

Screening Machine: This machine separates the perfectly sized granules from dust or oversized pieces. This ensures a consistent, market ready product. The rejected materials are sent back to the crusher and they are recycled back into the process

Packing machine: The last step of the production line is the Packing machine. The screened granules are packaged in this stage and are ready for market.

By integrating these machines from LANE Machinery, you create a streamlined organic fertilizer production line in Nepal that maximizes output, maintains quality, and minimizes physical labor.

Marketing and Sales: As a new production line you should primarily focus on the progressive farmers, cooperatives, and nurseries. Offer soil testing demonstrations to build trust. Participate in local agricultural fairs.

Choosing the right technology partner is critical for a small business. LANE Machinery offers turnkey services for entrepreneurs establishing an organic fertilizer production line in Nepal. We understand Starting a small-scale organic fertilizer production line in Nepal is more than a business, it’s a sustainable solution to a national challenge. Our production line creates high quality “black gold” from local resources. We help create a local product that empowers local farmers.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520