Pulse dust removal is an efficient and reliable dust removal equipment widely used in the industrial field for air pollution control. It combines the technological advantages of bag filtration and pulse cleaning, and performs particularly well in purifying dusty gases.

LANE can customize a pulse dust removal for you to meet any of your needs.

Pulse Dust Removal |

||

|---|---|---|

| Bag-filter number | Pulse Valve number | Parameter (mm) |

| 96 | 12 | 1530*2210*4200 |

| 150 | 15 | 2620*1870*4500 |

| 200 | 20 | 3500*1900*4500 |

| 300 | 25 | 4500*2000*4500 |

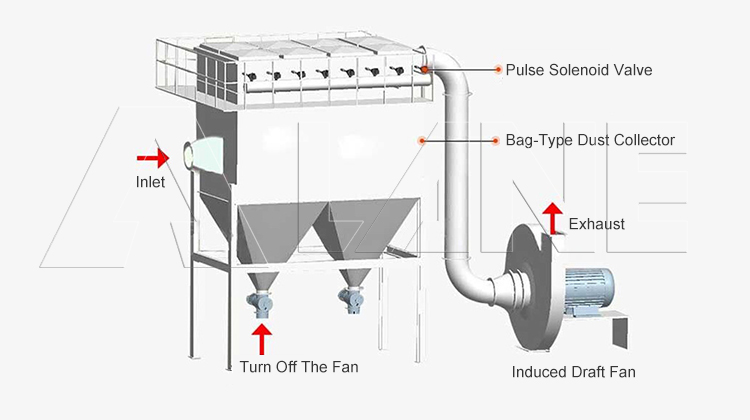

The pulse dust removal is composed of an ash hopper, an upper box, a middle box, a lower box, and other parts. The upper, middle, and lower boxes are divided into compartments.

During operation, dusty gas enters the ash hopper through the air inlet duct. Coarse dust particles directly fall into the bottom of the ash hopper, while fine dust particles enter the middle and lower boxes upwards with the turning of the airflow.

Dust accumulates on the outer surface of the filter bag, and the filtered gas enters the upper box to the clean gas collection pipe exhaust duct, and is discharged to the atmosphere through the exhaust fan.The dust cleaning process involves first cutting off the clean air outlet duct of the room, so that the bag in the room is in a state of no airflow passing through (stopping the air and cleaning the dust in each room).

Then, the pulse valve is opened and compressed air is used for pulse blowing to clean the dust. The shut-off valve is closed for a sufficient time to ensure that the dust peeled off from the filter bag settles in the ash hopper after spraying, avoiding the phenomenon of dust adhering to the adjacent filter bag surface with the airflow after leaving the filter bag surface. The filter bag is thoroughly cleaned, and the exhaust valve, pulse valve, and ash discharge valve are fully automatically controlled by a programmable controller.

For more information, please contact us by sending an inquiry today! We can help you!

High dust removal efficiency

The pulse cleaning efficiency of pulse bag dust collectors can usually reach more than 99%. For dust particles with a diameter of 0.3 microns, the cleaning efficiency can reach 99.9%.

Stable and reliable operation

The use of advanced pulse cleaning technology can effectively avoid problems such as filter bag blockage and condensation, ensuring long-term stable operation of the equipment.

Good economic benefits

During the operation of pulse dust removal, due to its high dust removal efficiency and stable performance, it can reduce energy consumption, material consumption and operating costs.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.