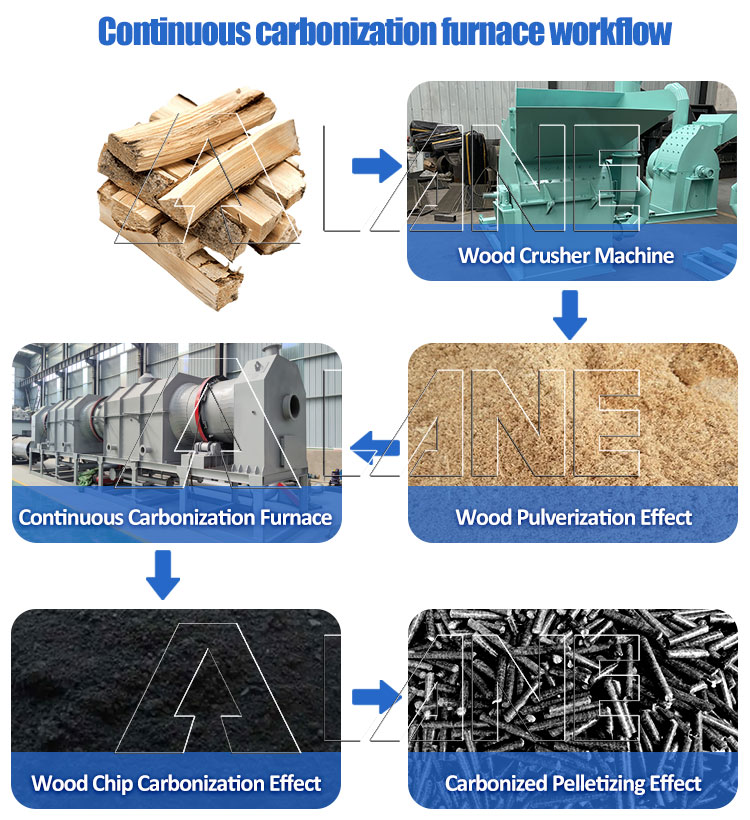

The rice husk carbonization furnace adopts a continuous production process, which can achieve rapid and efficient carbonization of rice husks. During the carbonization process, rice husks undergo continuous transportation, drying, carbonization, cooling, and other processes, ultimately transforming into high-quality rice husk charcoal.

LANE can customize a rice husk carbonization furnace for you to meet any of your needs.

Rice husk carbonization furnace |

||||

|---|---|---|---|---|

| Model | Production (kg/hour) | power | Drive form | Dimensions (L × W × H) |

| TDICA0.6 | 300-500 | 5.5 | Frequency Control | 10*1.1*1.2 |

| TDICA0.8 | 400-600 | 7.5 | 12*1.3*1.5 | |

| TDICA1.0 | 500-800 | 11 | 12*1.5*1.7 | |

| TDICA1.2 | 700-1200 | 15 | 14*1.7*1.8 | |

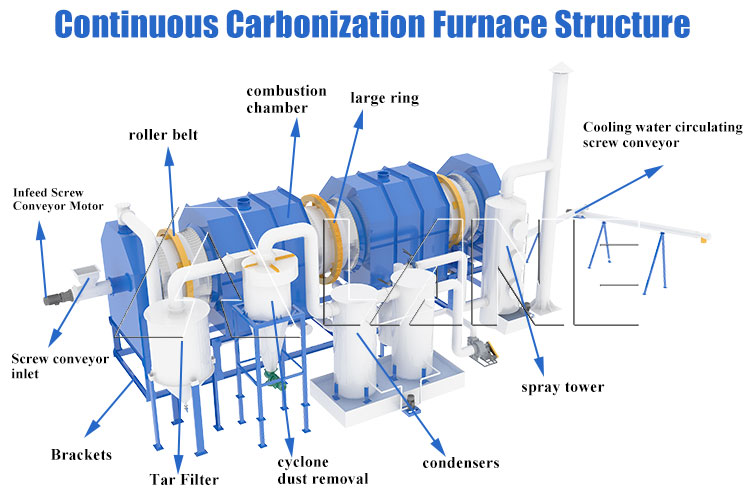

Our carbonization equipment is a horizontal drum carbonization furnace, which runs continuously for 24 hours, with continuous feeding and continuous carbonization. From feeding to carbonization, it takes about 20 minutes to carbonize rice husks, and about 10-100 tons of rice husks can be carbonized every day.

The rice husk carbonization furnace mainly adopts continuous carbonization technology, which realizes continuous carbonization of rice husks through rotating furnace body and double drum structure.

The feed grinding machine shell is welded with high quality material, and the feeding port is on the top of the mill. It can be matched with various forms of feed structure, and the hammer is arranged symmetrically. When the feed mixer works, the material enters the crushing chamber, and the material is gradually crushed and centrifuged under the action of high speed rotating hammer blow and sieve plate friction. Under the action of force and air flow, it is discharged through the bottom outlet.

This design not only improves production efficiency, but also optimizes the carbonization process, so that rice husks can be converted into high-quality carbon products in a shorter time.

For more information, please contact us by sending an inquiry today! We can help you!

Efficient

The rice husk carbonization furnace provides heat through an external heat source, making the temperature distribution inside the furnace uniform and improving the efficiency of dry distillation.

Environment protection

Compared with traditional combustion methods, the dry distillation process produces less waste gas and liquid, and is easy to treat, which meets environmental protection requirements.

Sustainable

Rice husks and other agricultural waste are renewable resources that can be converted into rice husk charcoal through dry distillation technology. This not only achieves effective utilization of resources, but also promotes the reduction and resource utilization of agricultural waste.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.