Rotary drum granulator is one of the key equipment in the fertilizer industry, suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers. The main working method is wet granulation of pellets. LANE can customize a rotary drum granulator for you to meet any of your needs.

Rotary Drum Granulator |

||||||

|---|---|---|---|---|---|---|

| Model | Drum size(mm) | Rotation Speed(rpm) | Thickness(mm) | Capacity(tph) | Power(kw) | Tilt Angle(°) |

| LAZR-1060 | Φ1000*6000 | 13 | 10 | 2-5 | 7.5 | 2-2.5° |

| LAZR-1260 | Φ1200*6000 | 13 | 10 | 3-6 | 11 | 2-2.5° |

| LAZR-1560 | Φ1500*6000 | 13 | 10 | 6-8 | 15 | 2-2.5° |

| LAZR-1870 | Φ1800*7000 | 13 | 12 | 8-10 | 18.5 | 2-2.5° |

| LAZR-2080 | Φ2000*8000 | 11.5 | 12 | 10-15 | 22 | 2-2.5° |

| LAZR-2290 | Φ2200*9000 | 11.5 | 14 | 15-20 | 30 | 2-2.5° |

| LAZR-2410 | Φ2400*10000 | 11.5 | 16 | 15-20 | 37 | 2-2.5° |

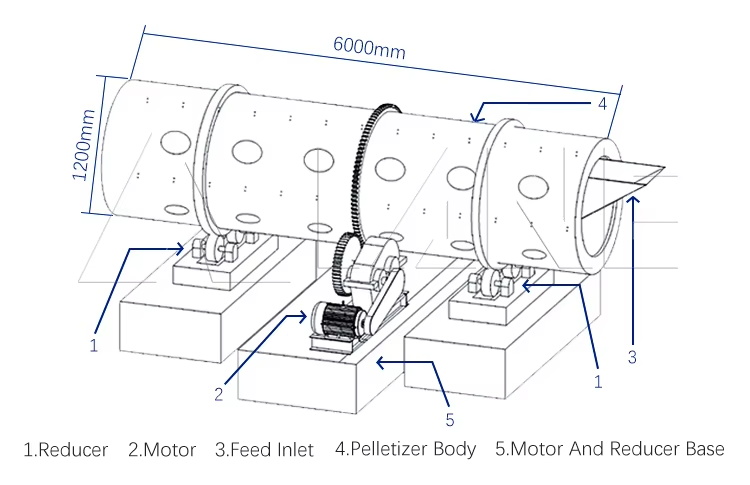

The powdered material to be granulated is added into the drum granulator from the feed end.

In the drum granulator, a certain amount of water or steam is introduced to make the fertilizer fully react chemically after being humidified in the drum.

With the help of the rotating motion of the drum, the materials are squeezed and agglomerated into spherical particles. The special structure in the drum helps to enhance this squeezing and agglomeration effect.

With the continuous rotation of the drum and the continuous entry of materials, the formed particles gradually increase.

Finally, these particles flow out from the discharge port, completing the granulation process.

If you have a better idea, or would like to do an experimental test as well, please contact us right away!

High ball formation rate

The ball forming rate reaches over 90%, with a small amount of returned material and a small particle size. Steam can be introduced to increase the temperature of the material, reducing the moisture content after ball forming and improving drying efficiency.

Anti corrosion

Rubber lining or acid resistant stainless steel lining plate is used, which is anti-corrosion, insulated, and not easy to stick to the cylinder.

Efficient

Large output, low energy consumption, simple operation, and low maintenance costs.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.