Table of Contents

With the rising demand of organic and sustainable agriculture, sheep dung fertilizer production line can be a highly profitable venture. sheep dung fertilizer is rich in nitrogen, phosphorus, potassium, and beneficial microorganisms. This makes it an ideal choice for improving soil fertility, promoting plant growth, and reducing chemical fertilizer usage.

Starting a sheep dung fertilizer production line, addresses the environmental problem of sheep manure waste and creates a stable and profitable business opportunity. In this guide we will explore how to start a sheep dung fertilizer production line using LANE Heavy Industry’s machinery.

Sheep dung fertilizer is highly effective organic fertilizer due to its rich nutrient content. It contains 50-55% organic matter and 6-8% nitrogen, phosphorus, and potassium. This is significantly higher than cow or pig manure. These essential elements improve soil structure and enhance crop yield. Sheep dung is readily available in regions with sheep farming, making it cost effective and sustainable option for fertilizer production. Moreover, organic fertilizers like sheep dung fertilizers are high in demand due to the growing preference for sustainable agricultural practices.

When setting up a sheep dung fertilizer production line, the machinery will determine the efficiency and product quality. LANE Heavy Industry’s machinery offers a range of solutions designed to handle the different stages of production effectively.

3.1. Raw Material Handling

The first step in the production process is collecting and transporting sheep dung to the production facility. LANE Heavy Industry provides equipment for raw material handling. This includes conveyor belts and loading machines. They move the sheep dung easily from one stage to another.

3.2. Fermentation and Decomposition

Fermentation will determine the final quality of your fertilizer. It is an essential process for breaking down the organic matter in the sheep dung. LANE Heavy Industry offers automatic fermentation tanks that control temperature and moisture. This ensures that the sheep dung decomposes efficiently and is safe to use as fertilizer.

3.3. Grinding and Mixing

Once the sheep dung has been fermented, it needs to be ground into a fine powder to improve its mixing capabilities. LANE Heavy Industry’s crushers are designed to process the compost efficiently and break it down into smaller particles.

3.4. Granulating

Granulation is the most important step after composing. It converts sheep manure compost into easy to apply granules. LANE Heavy Industry deploys Stirring Pin Granulators or Rotary drum granulator that turn sheep dung compost into uniform granules that can easily spread on fields. The granules also have an extended shelf life compared to powdered fertilizers.

After Granulation, the granules need to be dried to remove excess moisture. LANE Heavy Industry’s Rotary dryers are ideal for drying the granules to the right consistency. While Rotary Cooling system ensures that they are safe to handle and package.

3.6. Packaging

The final step is packaging the fertilizer into bags or other containers. LANE Heavy Industry’s automated packaging machines streamline this process.

Starting a sheep dung fertilizer production line requires careful planning and proper execution. Here’s a breakdown of the process.

Step 1: Planning and Research

Before investing in the machinery, you must conduct thorough research. You must understand the market demand for sheep dung fertilizer in your region and identify potential customers such as farms, garden centers, and agricultural cooperatives.

Step 2: Sourcing Sheep Dung

The next step is sourcing sheep dung. You will need a reliable supply of fresh dung. You can obtain that from nearest local sheep farms. You should consider making a partnership with farmers to ensure a steady supply of raw material.

Step 3: Selecting the Machinery from LANE Heavy Industry

Lane Heavy Industry’s machinery is specifically designed for processing animal waste including sheep dung. Invest in equipment such as fermentation tanks/ compost turner, grinding machines, granulators, drying units and packaging machines to set up a seamless production line.

Step 4: Setting Up the Production Facility

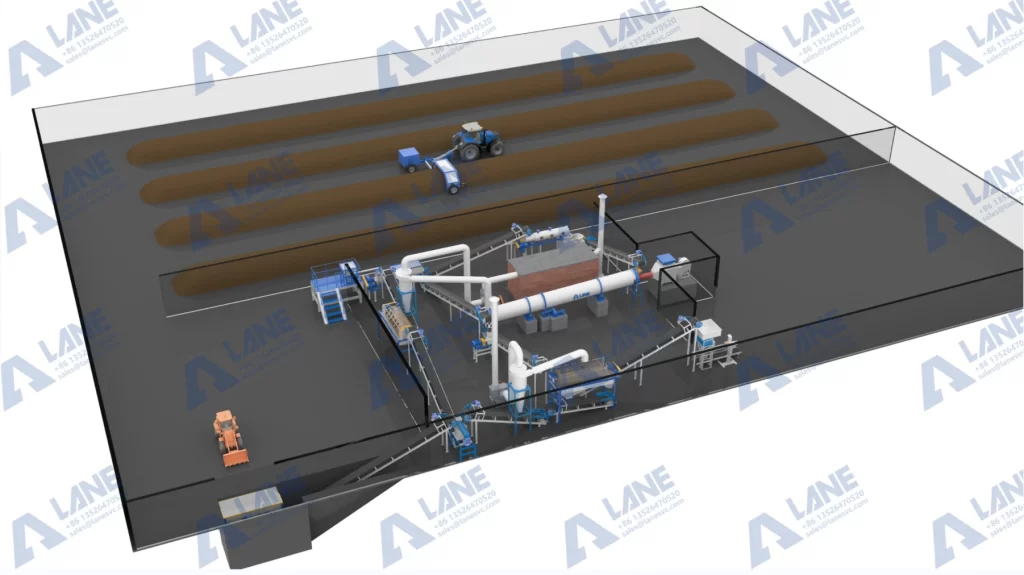

You must build a facility that can accommodate the machinery and provide enough space for raw material storage, production, and packaging. The factory layout should facilitate a smooth flow from one stage to the next. LANE provide excellent factory layout design that help with smooth flow of the material and avoid contamination.

Step 5: Training Staff

You must consider training your staff on how to operate the machinery and maintain the sheep dung fertilizer production line. LANE heavy industry provides excellent customer support and training programs for machine operation. This ensure that your team is well-equipped to run the line efficiently.

Now that the machinery is set up and staff is trained, you can start the production.

Fermentation

The first stage involves fermenting the sheep dung. This process breaks down organic matter, kills harmful pathogens and weeds. The fermentation process takes several weeks. The time depends on raw material, temperature and humidity.

Grinding

After fermentation, the sheep dung compost is sent to the LANE vertical crusher where the compost is grinded to fine particles. It makes it easy to mix with other ingredients, like mineral additives and improves its effectiveness as fertilizer.

Granulation

Granulation turns the powdered sheep dung into uniform pellets. This step makes the fertilizer easier to apply, store and transport.

Drying and Cooling

The granules are then dried to remove any excess moisture and then conveyed to cooler to prevent the pellets from sticking together.

Packaging

Finally, the finished fertilizer is packaged in bags, ready to be sold or distributed. The packaging process helps ensure that the product is protected from moisture and contamination.

Starting a sheep dung fertilizer production line is a promising business that combines environmental protection and profitability. It represents one of the most accessible entry points into the bio-economy. The raw material costs are negligible; technology is mature and the market demand for sheep dung fertilizer is continuing to rise as agriculture moves decisively toward organic practices. By choosing high-quality machinery from LANE Heavy Industry, you can ensure efficient processing and production of premium sheep dung fertilizer. Invest in a sheep dung fertilizer production line today and seize the opportunity in the booming organic agriculture industry.

Q1: What are the benefits of using sheep dung fertilizer?

Sheep dung fertilizer is rich in essential nutrients like nitrogen, phosphorus, and potassium, which are vital for plant growth. It improves soil fertility and is an eco-friendly alternative to chemical fertilizers.

Q2: How long does it take to produce sheep dung fertilizer?

The time taken to produce sheep dung fertilizer varies based on the processing stages. Fermentation can take a few weeks, while grinding, granulation, and drying typically take a few days to a week.

Q3: Can I use sheep dung fertilizer for all types of crops?

Yes, sheep dung fertilizer is suitable for most crops, including vegetables, fruits, and grains. However, it is essential to test the fertilizer for specific crops before large-scale use.

Q4: Where can I buy machinery for sheep dung fertilizer production?

You can buy high-quality machinery from LANE Heavy Industry, which specializes in fertilizer production lines, including equipment for handling, fermenting, granulating, and packaging sheep dung fertilizer.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520