Brand: LANE

Production line advantages:

High production efficiency,1-20tons/h

Applicable materials:

Wine dregs, soy sauce dregs, vinegar dregs, furfural dregs, xylose dregs, enzyme dregs, sugar dregs, medicine dregs.

Warranty: 5 Years

Delivery Time: Within 45 days

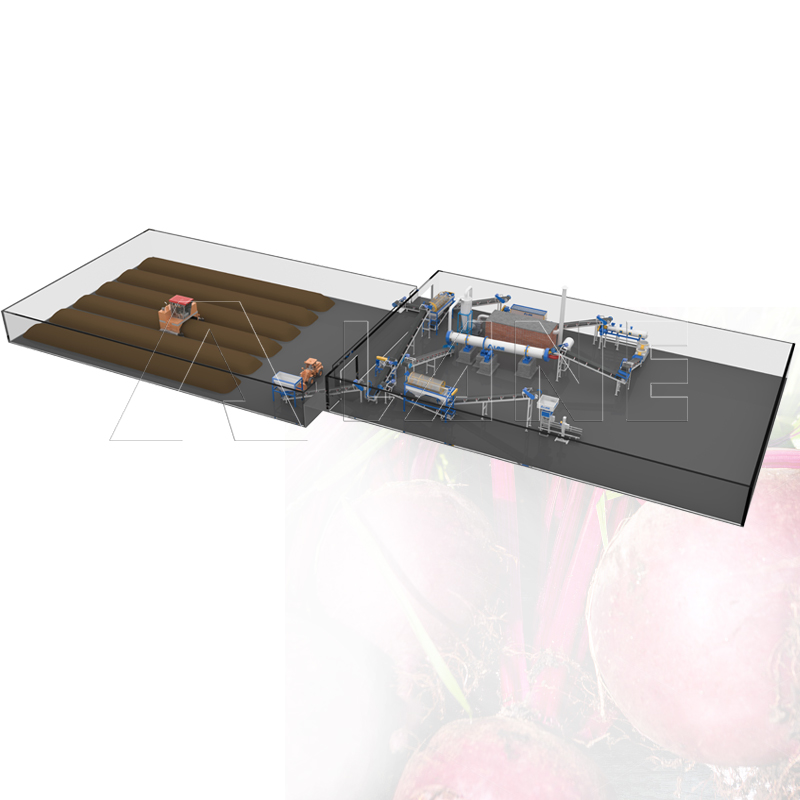

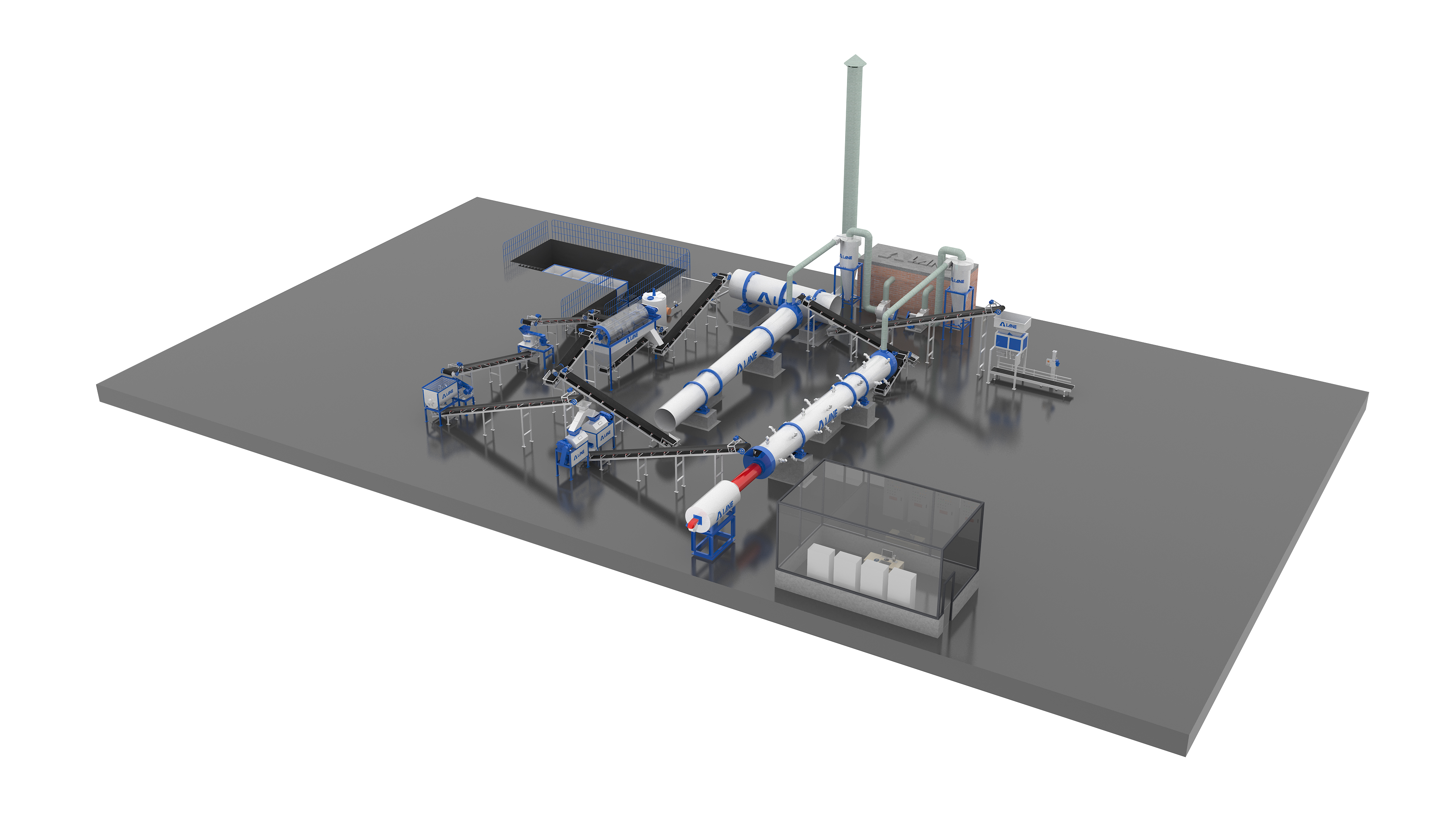

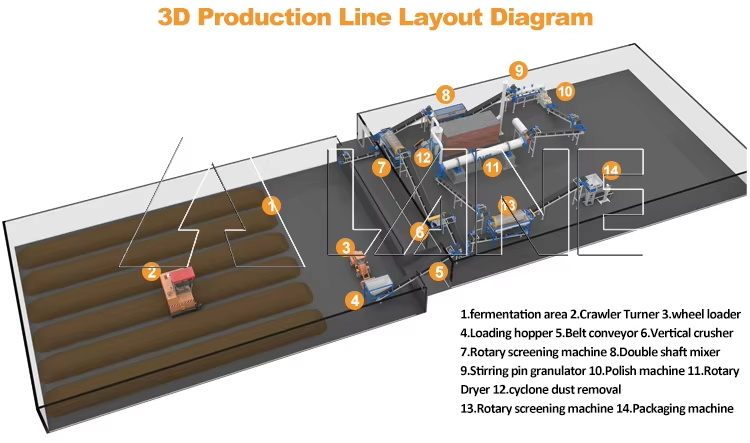

The sugar residue organic fertilizer production line is a process of converting the remaining sugar residue from sugarcane sugar production into organic fertilizer through a series of procedures. Sugar dregs are by-products from the production of foods such as candies, syrups, cookies, etc. They can be converted into organic fertilizers by specific methods, as they contain a large amount of biodegradable substances.

Lane can customize your own sugar residue organic fertilizer production line to meet any of your needs.

You can click on the numbers to see detailed pictures!

How to convert sugar residue into organic fertilizer?

1. Collection of sugar residues. Collect the sugar residue into a container, such as a bucket or compost pile.

2. Add composting agent. Add composting agents such as chicken manure, straw, and straw to the sugar residue. These composting agents increase the organic matter content and speed up the fermentation process.

3. Composting. After adding the composting agents, the sugar residue and composting agents are mixed well and then composted. At least 3 months of composting is required when processing sugar residue to ensure that the organic matter-containing material is fully decomposed.

4. crushing the fermented sugar residue organic matter and then pelletizing the fertilizer.

5. the treated organic fertilizer can be used as raw material for planting and to improve the growth of plants.

If you have a better idea, or would like to do an experimental test as well, please contact us right away!

Shown below is our sugar residue production line case, please contact us for more information.