When we talk about innovation in modern fertilizer plants, the spotlight usually falls on granulators, dryers, or advanced fermentation systems. Yet hidden behind the scenes, performing tirelessly without drawing attention, are the machines that quietly keep the entire process moving. Among them, screw conveyors in modern industry are the true unsung heroes.

From transporting raw manure into fermentation pits to moving finished granules toward packaging lines, screw conveyors ensure continuous, efficient, and reliable material handling in fertilizer production. Their importance in the fertilizer equipment industry is often underestimated, but without them, even the most sophisticated granulation line would stall.

The Principle Behind Screw Conveyors in Modern Industry

At their core, screw conveyors in modern industry are built on a simple principle: a rotating helical screw inside a trough or tube moves material from one point to another. Originating from Archimedes’ ancient screw pump, this design has been refined for industrial-scale operations.

Components: Screw blade (flighting), trough or casing, shaft, bearings, and drive unit.

Operation: As the screw rotates, friction between the material and the flights pushes bulk solids forward.

Flexibility: They can transport powders, granules, semi-wet materials, and even sticky substances like animal manure.

This versatility makes Screw Conveyors indispensable for fertilizer plants, where raw materials vary in moisture, density, and particle size.

The Role of Screw Conveyors in Fertilizer Production

1.Raw Material Feeding

In organic fertilizer plants, raw inputs such as livestock manure, crop straw, or municipal sludge must be moved to pre-treatment systems. screw conveyors in modern industry handle this efficiently, even when the material is semi-wet or uneven in size.

2.Fermentation and Composting Support

During composting, materials need to be transferred between piles, mixers, or fermentation tanks. Inclined screw conveyors are often used to elevate compost into hoppers or distribute it evenly along fermentation lanes.

3.Crushing and Mixing Lines

After pre-treatment, organic matter is crushed and blended. Screw conveyors transport materials between crushers, mixers, and storage bins, ensuring that the process remains continuous.

4.Granulation Line

In granulation, conveying is essential to move semi-processed material into granulators like rotary drum granulators or stirring pin granulators. Without screw conveyors, maintaining a steady feed would be impossible.

5.Drying and Cooling

Post-granulation, fertilizers pass through dryers and coolers. Screw conveyors transfer hot or cooled material with precision, minimizing spillage.

6.Screening and Recycling

Separated oversized or undersized particles from rotary screeners are redirected back into the production cycle by screw conveyors, closing the loop in fertilizer lines.

7.Final Packaging

Finished fertilizers must reach packaging machines in consistent flow. Screw conveyors deliver product steadily, ensuring accurate weighing and sealing.

In essence, from start to finish, screw conveyors act as the backbone of a organic fertilizer production line.

Types of Screw Conveyors Used in Modern Industry

Different stages of fertilizer production demand different conveyor designs.

Horizontal Screw Conveyors

Ideal for moving raw manure, compost, or granulated fertilizer over short distances.

Commonly used between mixers, granulators, and dryers.

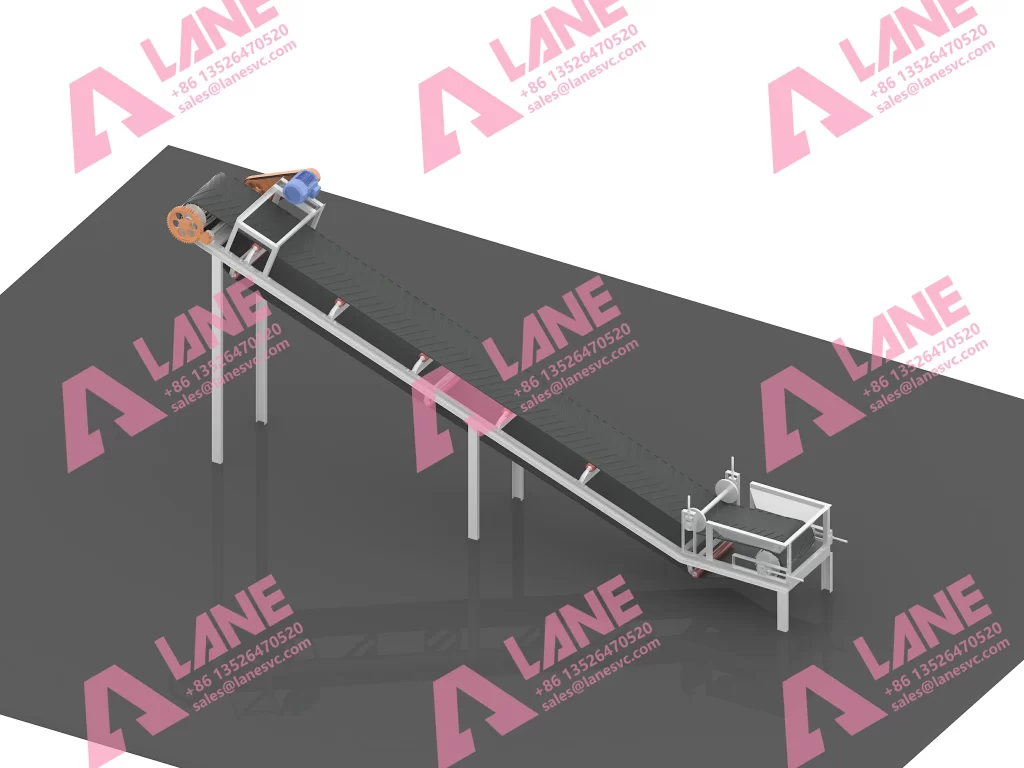

Inclined Screw Conveyors

Used to elevate compost or fertilizer to higher levels, such as feeding hoppers or fermentation tanks.

Often integrated with vertical systems to save space.

Vertical Screw Conveyors

Compact and powerful, designed for moving material vertically.

Useful in multi-story fertilizer plants where space is limited.

Shaftless Screw Conveyors

Perfect for sticky or fibrous materials like animal manure or sludge.

No central shaft means reduced clogging and easier cleaning.

By selecting the right type, a fertilizer plant can ensure smooth and reliable operations across every stage.

Advantages of Screw Conveyors in Fertilizer Equipment

Efficiency in Material Handling: Continuous operation reduces downtime and keeps production consistent.

Versatility Across Materials: From dry powders like phosphate to semi-wet compost, Screw Conveyors adapt easily.

Compact Design: Their ability to operate horizontally, vertically, or at an incline makes them space-saving.

Dust Control: Enclosed casings minimize dust emissions, critical in fertilizer plants where dust can be hazardous.

Durability: Built with wear-resistant materials, they withstand abrasive fertilizers and corrosive organics.

Automation Integration: Easily linked with PLC controls, Screw Conveyors fit seamlessly into modern automated production lines.

Case 1: Organic Fertilizer Plant in Vietnam

A large pig farm in Vietnam installed an automated organic fertilizer production line. The system relied on multiple screw conveyors in modern industry to move manure from dewatering machines to composting tanks, and later into granulators. By automating transport, labor costs dropped by 30%, while production capacity nearly doubled. The conveyors proved especially valuable in handling high-moisture manure, which previously slowed operations.

Case 2: Liquid Fertilizer Facility in Brazil

In Brazil, a cooperative producing liquid fertilizers needed a way to move semi-dissolved organic matter from mixing tanks to filtration systems. Inclined screw conveyors in modern industry provided a steady flow, preventing sediment buildup. By ensuring consistent feeding, the plant reduced downtime and improved product clarity, making their fertilizers more suitable for drip irrigation systems.

The Future of Screw Conveyors in Modern Industry

Smart Monitoring: Sensors embedded in screw conveyors in modern industry can now track speed, load, and wear, alerting operators before failures occur.

Sustainable Materials: New alloys and coatings will make conveyors more resistant to corrosion and abrasion, extending service life in fertilizer environments.

Energy Efficiency: Variable frequency drives (VFDs) help adjust conveyor speed to material flow, reducing energy consumption.

Integration with Circular Agriculture: As more plants process animal waste, food residues, and sludge into fertilizer, Screw Conveyors will remain crucial for handling difficult, variable feedstocks.

In the fertilizer equipment industry, machines like granulators and dryers often capture the spotlight, but screw conveyors in modern industry are the steady force that ensures production never stops. From raw manure handling to final packaging, they enable continuity, efficiency, and automation.

Their adaptability, durability, and quiet reliability make them indispensable in both organic and chemical fertilizer lines. While they may never be the showpiece of a production facility, screw conveyors in modern industry remain the unsung heroes — the silent partners that keep modern fertilizer plants running smoothly, day after day.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520