Under the current trend of environmental protection and sustainable development, how to efficiently treat organic waste has become the focus of many companies. Especially in industries such as livestock and poultry farming, agricultural waste treatment, and urban sludge treatment, it is crucial to choose a fermentation equipment that is both efficient and environmentally friendly. LANE vertical stainless steel fermentation tanks can help companies achieve green production and resource utilization with their outstanding technical advantages and highly automated design.

Why invest in vertical stainless steel fermentation tanks?

Many organic fertilizer plants face many difficulties in treating organic waste: old equipment and low treatment efficiency; long fermentation time and large floor space; insufficient automation and high labor costs; after-sales service is not guaranteed and equipment failure rate is high. In response to these pain points, LANE, as a fermentation tank supplier, provides efficient, energy-saving and environmentally friendly solutions.

LANE recommends using fermentation tanks to produce biofertilizers mainly for two features: vertical design + stainless steel.

1. Short fermentation time and high efficiency

Compared with the 10-20 days of fermentation time required for traditional fermentation tanks, the vertical stainless steel fermentation tank can complete the entire fermentation process in only 8-10 hours. This significant improvement enables composting plants to complete production tasks faster and significantly shorten the production cycle.

2. Small footprint and high space utilization

Vertical fermentation tanks are vertical sealed structures with a very small footprint. Taking an annual output of 10,000 tons as an example, the plant area only needs 30 square meters, while traditional fermentation tanks require 1,000 square meters. This is a great space optimization for composting plants with limited space.

3. Highly automated, saving labor costs

The equipment supports PLC program control and remote monitoring. The entire fermentation process only requires 1-2 operators to complete. The automatic loading and unloading system further reduces manual intervention, which not only simplifies the operation process, but also effectively reduces labor costs and saves a lot of operating costs of composting plants.

4. Long service life and cost saving

The fermentation tank adopts a three-layer anti-corrosion structure, which can resist the corrosion of strong acid and strong alkali environment, and the service life of the equipment is more than 10 years. This means that the fermentation plant does not need to replace equipment frequently, and in the long run, the maintenance cost of the fermentation equipment will be greatly reduced.

5. Environmental protection and high efficiency

The LANE vertical stainless steel fermentation tank adopts an advanced heat exchange system to achieve efficient deodorization during the fermentation process, and the waste gas treatment is environmentally friendly and compliant, with a deodorization rate of more than 99%. In addition, the equipment has low energy consumption, which can greatly reduce energy consumption and provide strong support for the green production of fertilizer enterprises.

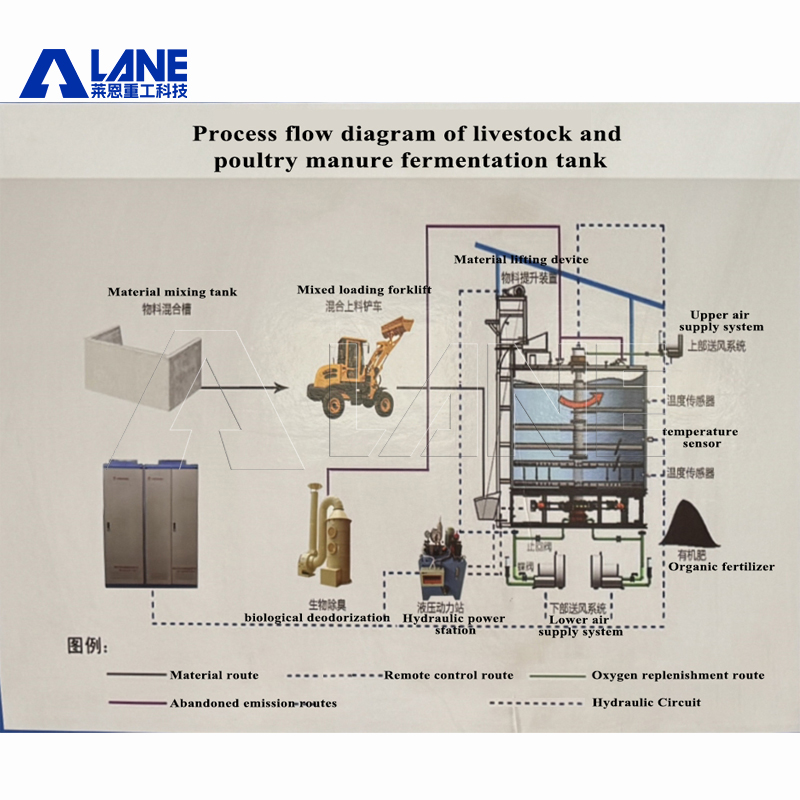

The excellent performance of the LANE vertical stainless steel fermentation tank comes from its six core technology systems:

1. Insulation system: polyurethane materials are used to ensure the normal operation of the equipment throughout the year, and the fermentation results are stable even in low temperature environments.

2. Hydraulic drive system: provides strong thrust for loading and unloading, improves overall production efficiency, and ensures efficient work.

3. Heat exchange system: reduces energy consumption through efficient heat circulation, improves energy utilization, and achieves economic energy saving.

4. Automatic loading and unloading system: patented unloading device controls the unloading amount, speeds up the unloading speed, and further improves production efficiency.

5. Polygonal base design: The stainless steel fermentation tank has a solid and stable structure, which is not only beautiful but also saves space.

6. Spindle drive system: Made of high-strength Q345B material, it ensures the reliability and durability of the equipment for long-term operation.

LANE vertical stainless steel fermentation tanks have a wide range of applications, meet the needs of multiple industries, and are suitable for a variety of organic waste treatment scenarios, including livestock and poultry manure, agricultural waste, domestic garbage and municipal sludge. LANE not only provides high-performance fermentation equipment, but also customizes complete production line solutions for customers. We provide customers with on-site project case demonstrations and professional 3D design rendering services, so that customers can intuitively see the layout and operation of the equipment in the actual scene.

In addition, LANE also provides full-range technical support from equipment installation and commissioning to production training to ensure that the equipment is running efficiently while helping customers achieve production automation and maximize profits.

Welcome partners from all over the world to contact us and start making money together. Contact us now for free to learn more details about vertical stainless steel fermenters and get customized solutions!