A twin shaft mixer is a device that uses two symmetrically arranged mixing shafts for material mixing, especially suitable for mixing dry hard, semi dry hard, viscous and other materials. It can be used for the production of organic and compound fertilizers, especially popular in high-yield fertilizer industries.

LANE can customize a twin shaft mixer for you to meet any of your needs.

Twin Shaft Mixer |

||||||

|---|---|---|---|---|---|---|

| Model | Capacity(tph) | Drum Size(mm) | Size(mm) | Power(kw) | Drum Volume(m³) | Mixing Shaft Size(mm) |

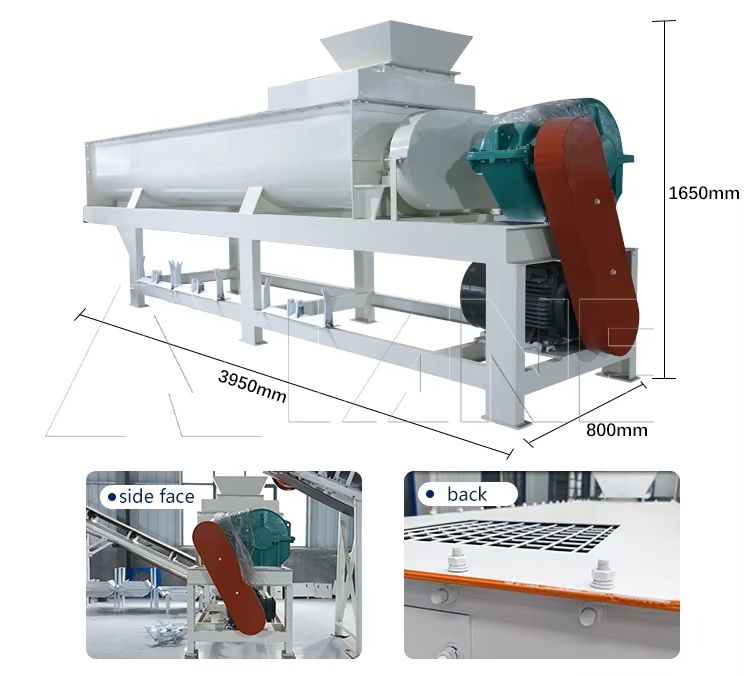

| LAM-0830D | 6-10T/H | 800*3000 | 3950*1650*800 | 18.5 | 1.6 | 102*8 |

| LAM-0840D | 8-12T/H | 800*4000 | 4950*1650*800 | 18.5 | 2.1 | 102*8 |

| LAM-1040D | 10-14T/H | 1000*4000 | 4950*2050*1000 | 22 | 2.6 | 118*10 |

| LAM-1050D | 12-16T/H | 800*4000 | 5950*2050*1000 | 22 | 3.3 | 133*14 |

| LAM-1240D | 12-16T/H | 1200*4000 | 5150*1960*1160 | 30 | 3.1 | 159*17.5 |

| LAM-1250D | 14-18T/H | 1200*5000 | 6150*2250*1200 | 30 | 3.9 | 159*17.5 |

| LAM-1550D | 16-20T/H | 800*4000 | 6600*2200*1250 | 30 | 4.9 | 219*20 |

| LAM-1560D | 18-22T/H | 800*4000 | 7250*2500*1500 | 30 | 5.9 | 219*20 |

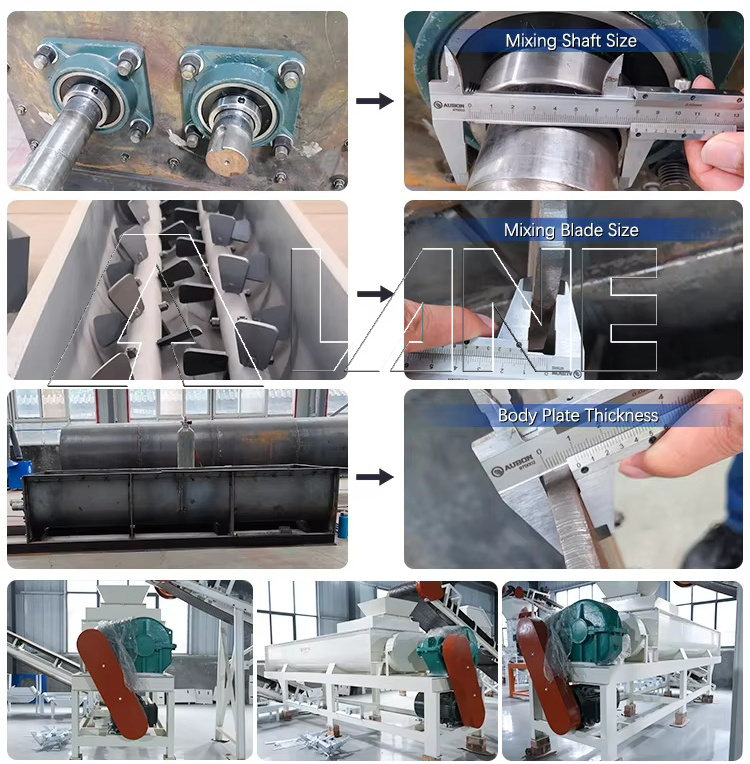

The barrel of the twin shaft mixer is equipped with paddles that rotate in opposite directions. The paddles are at a certain angle to stir the materials axially and radially, so that the materials are quickly mixed and evenly mixed.

Then the motor drives the shaft to rotate through the belt drive to the reducer. The speed of the shaft and the structure of the paddles will weaken the gravity of the materials. With the lack of gravity, the differences in particle size and specific gravity between the materials are gradually ignored during the mixing process. Even if there are differences, a good mixing effect can be achieved under the rapid and intense tumbling and throwing of the mixing blades.

This series of twin shaft mixer is a new generation of mixing equipment developed by our company. It has a high degree of mixing and a small amount of residue. It is suitable for mixing more than two fertilizers, additive premixes, and feed, concentrated feed, additive premixes, etc.

It can make the materials fully mixed, thereby improving the uniformity of mixing; the novel rotor structure can effectively reduce the amount of material residue. The special rotor design of this machine can also crush larger materials. The overall structure is also more reasonable and beautiful, and it is also convenient to operate and maintain.

For more information, please contact us by sending an inquiry today! We can help you!

Efficient mixing

The twin shaft mixer uses two symmetrically arranged mixing shafts, which can complete a large amount of material mixing work in a short time, and ensure that the materials are fully mixed during the mixing process to ensure the uniformity of the mixed materials.

Compact structure

The twin shaft mixer has a compact structure and a small footprint, which is suitable for various on-site conditions, especially for occasions with limited space.

Simple operation

The twin shaft mixer has a simple structure and is easy to maintain, reducing the cost of operation and subsequent maintenance.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.