In the fertilizer industry, fertilizer coating has become a common and essential practice. Coating fertilizers with a coating machine not only improves the appearance of the fertilizer, but also protects the composition of the fertilizer. It protects the fertilizer from environmental factors such as moisture and air. In some cases, manufacturers use coating to control the release rate of fertilizer effects.

Given the importance of fertilizer coating, a good coating machine is essential. When buying a machine, you must have a detailed understanding. This article can help you clearly understand the machine components and make a smarter choice.

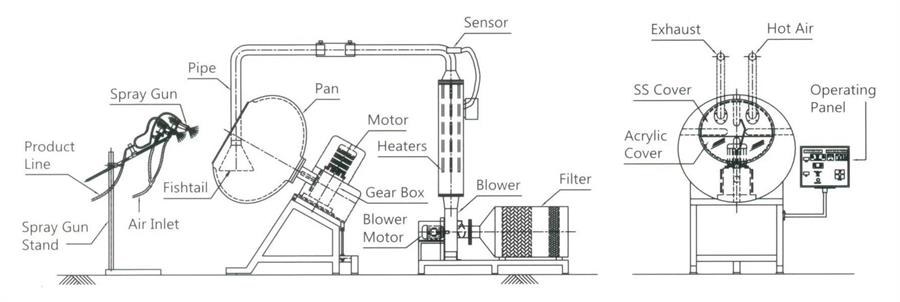

The coating pan is a key component of the coating machine. It is a large rotating drum used to carry out the coating process. It can hold and tumble the material while spraying the coating solution to ensure that the material is evenly coated while moving. The coating pan is usually made of stainless steel, which is durable and easy to clean.

The spray system usually includes a nozzle, a spray gun, and a solution tank. The nozzle can be high-pressure or low-pressure.

At high pressure, the solution forms fine droplets when sprayed, which can provide precise coating and is suitable for fertilizers that require a specific coating thickness. At low pressure, the sprayed droplets are larger and cover a larger area. This is usually used to spray larger surfaces.

It is important to note that the nozzles are usually made of stainless steel or plastic. They need to be cleaned and inspected regularly to prevent clogging and wear.

The agitation system usually includes baffles and agitators. Baffles are generally fixed panels fixed to the coating pan, which disrupt the airflow and movement of materials. It can prevent the materials from sliding continuously in the coating pan and help to evenly apply the coating solution to each material.

The agitator is a rotating device that can further mix the materials. Keeping the materials in constant motion can better evenly apply the coating solution.

The motor provides the power required for the entire equipment operation. All moving parts depend on it to operate. These parts include the coating pan, blower or fan, agitator, etc. Ensure that all parts of the coating process can operate normally to ensure the uniformity and quality of the material coating.

The blower is part of the air handling system of the equipment. It can generate and direct airflow into the coating system. It has the following main functions:

Dry the coating. The airflow ensures that the layer dries quickly and evenly, preventing caking or uneven surface.

Maintain temperature and humidity. The blower helps to control the temperature and humidity in the coating chamber, which is essential for the coating to work optimally and dry.

Remove excess solvent. Helps maintain an efficient and safe coating environment.

The hot air device is used to supply heated and conditioned air to the coating chamber. It includes adjustable heating elements to achieve the required air temperature.

The hot air device can also be used to evaporate excess solvent and moisture during the coating process. By adjusting the air flow, the heat is evenly distributed throughout the coating chamber, which is conducive to the rapid evaporation of liquids.

The electrical control cabinet is the central unit of the entire coating machine, which is used to control all electrical components and control systems. It mainly includes 2 components:

PLC. This is the brain of the coating machine and controls various automated processes such as the operation of the spray system, air handling system and heating elements.

Human machine interface. For interaction between operators and machines, you can use it to set and adjust various process parameters, such as temperature, air flow and spray rate. It can also be used to display real-time data such as temperature and humidity. If an abnormality is found, you can identify and solve the problem in time.

Every coating machine must be equipped with a safety system, which is used to protect operators and ensure safe operation. The safety system includes an emergency stop button, which will immediately stop the operation if there is a risk. The system also has an alarm button, which can be used to remind operators to pay attention to problems such as temperature and humidity deviations and pressure abnormalities, so that operators can take corrective measures in time.

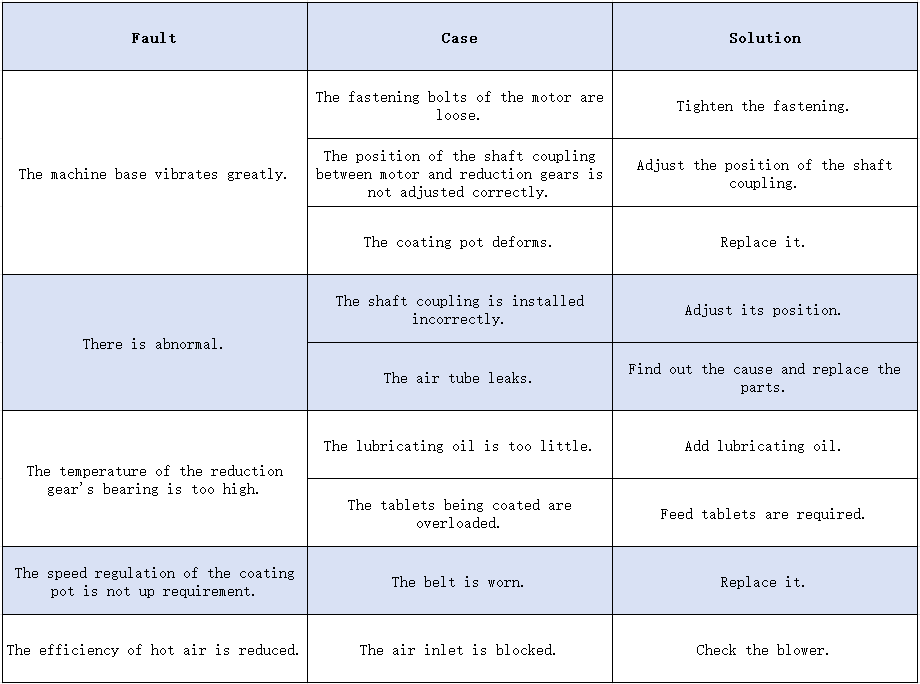

You may encounter some problems during the use of the machine. Here are some common causes and solutions for your reference.

As a leading fertilizer equipment supplier in China, LANE has helped more than 30,000 customers get the products they need. We provide a variety of equipment, including coating machines, granulators, mixers, tumblers, etc. In addition, we have a professional design team to help you. If you encounter any problems during the installation process or machine operation, you can contact us at any time.

In addition, LANE also provides flexible transportation solutions, no matter where the products are, they can be delivered directly to your designated place.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales2@lanesvc.com

Contact number: +86 15515885328

Whatsapp: +86 15515885328