Cassava is an important crop in many parts of the world. People use it to make starch, food, animal feed, and industrial products. But after processing cassava, factories produce a large amount of leftover material. In the past, this residue was seen as useless waste. Today, more people are learning how to use cassava residue to produce organic fertilizer in a safe and practical way.

Cassava residue contains a lot of organic matter. This is good for soil and plants. However, it also has high moisture and a strong smell. If it is not treated correctly, it can cause problems. It may attract insects or pollute nearby land. That is why turning it into organic fertilizer needs a clear process and suitable equipment. Many factories and farms now choose this method because it helps solve two problems at once. It reduces waste, and it provides fertilizer for agriculture. This is why use cassava residue to produce organic fertilizer is becoming more common in modern farming.

Below are six simple steps that explain how the process works in real production.

When cassava residue first comes from the factory, it is usually in big wet lumps. These lumps are hard to mix and hard to ferment. A vertical crusher or hammer crusher is used to break them into smaller pieces.

After crushing, the material becomes more even. This helps all the following machines work better. It also helps save time and energy during production. Using proper crushing is the first step if you want to use cassava residue to produce organic fertilizer efficiently.

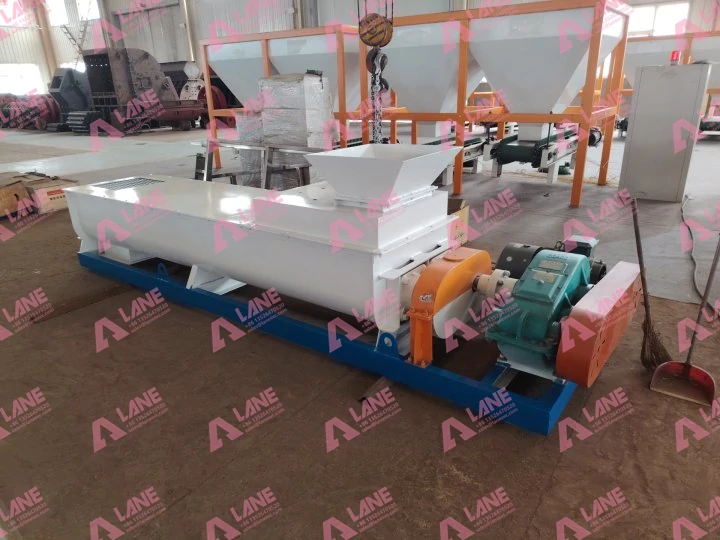

After crushing, the residue goes into a mixing machine. Common mixers include horizontal mixers and double-shaft mixers. At this stage, other materials are added.

For example, animal manure or fermentation bacteria can be mixed in. This improves nutrient balance. Mixing also makes sure every part of the material is treated the same way. This step is crucial when you use cassava residue to produce organic fertilizer safely and evenly.

Fermentation is the most important step. Compost turning machines or fermentation tanks are used here. These machines help air go into the material and keep the temperature at a good level.

During fermentation, microorganisms break down the organic matter. The bad smell slowly disappears. Harmful substances are reduced. After this step, the material becomes safer for crops and soil. Proper fermentation is a key part to use cassava residue to produce organic fertilizer effectively.

This process usually takes several days. Machines help reduce manual work and keep conditions stable.

After fermentation, the material is still wet. High moisture makes storage difficult. To solve this problem, drying machines are used.

A rotary dryer or belt dryer removes extra water. After drying, the fertilizer is lighter and easier to store. This step also helps prevent mold during storage and transport. Drying correctly is another step to use cassava residue to produce organic fertilizer properly.

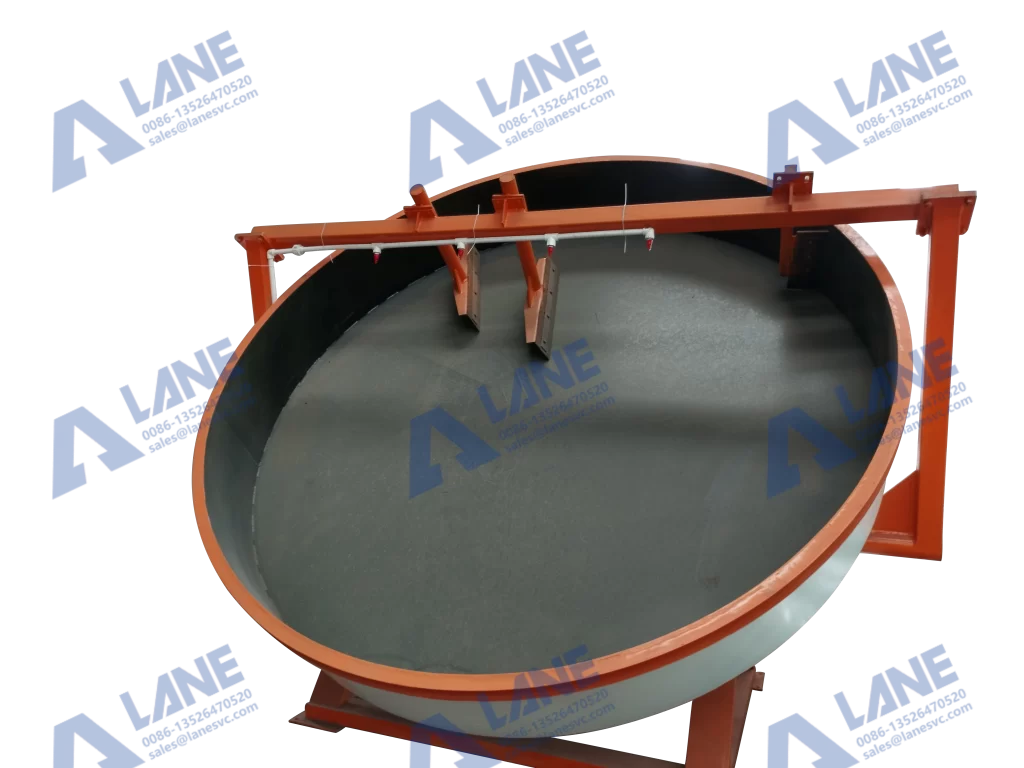

Many farmers prefer pellet fertilizer. It is clean and easy to apply. That is why granulation is an important step.

Disc granulators or rotary drum granulators turn loose material into round pellets. These pellets are strong enough for transport and do not break easily. They also look more professional in the market. Granulation ensures that every producer can use cassava residue to produce organic fertilizer in a usable and convenient form.

After granulation, not all pellets are the same size. A screening machine separates qualified pellets from unqualified ones. Unqualified material can be reused.

Finally, packing machines pack the finished fertilizer into bags. This makes storage and sales more convenient. Proper screening and packing help everyone use cassava residue to produce organic fertilizer efficiently.

This method helps protect the environment. It reduces waste and pollution. At the same time, it provides organic fertilizer that improves soil quality.

Organic fertilizer helps soil hold water and nutrients. It supports long-term farming instead of short-term results. That is why this solution fits modern agriculture very well. Using this complete process ensures that more farms can use cassava residue to produce organic fertilizer safely.

Our company has more than 20 years of experience in fertilizer machinery manufacturing. We focus on practical equipment that works in real production conditions.

When customers want to start this project, we design complete production lines. Our engineering team adjusts machines based on raw material and capacity needs. We provide crushers, mixers, fermentation tanks, compost turning machines, dryers, granulators, screening machines, and packing machines. Every machine is matched to the production line for smooth operation. This makes it easier for clients to use cassava residue to produce organic fertilizer successfully.

We help with installation, testing, and worker training. After the line starts running, we continue to provide maintenance and technical support. This ensures that the production line works efficiently for a long time.

Our equipment meets ISO9001 and CE standards. We specialize in organic fertilizer equipment, compound fertilizer equipment, NPK production lines, and full fertilizer plant solutions. Clients who choose to use cassava residue to produce organic fertilizer with us get both machines and long-term service.

As environmental awareness grows, more factories will look for better waste solutions. Cassava residue has real value when treated correctly.

In daily operation, this kind of production line is also easy to manage. Most machines run automatically after setup. Workers only need basic training. This helps reduce labor pressure and operating costs. Stable equipment performance helps keep product quality consistent, which is important for long-term market trust.

With simple steps, clear machines, and professional support, this method is easy to understand and practical to use. It is a good choice for factories and farms that want long-term benefits. Turning cassava residue into organic fertilizer is no longer wasteful—it is smart, environmentally friendly, and profitable.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520