In the age of sustainable agriculture, organic waste is no longer seen as a problem—it’s a resource. One of the most efficient ways to convert organic waste into valuable fertilizer is through a vermicompost production line setup. Vermicompost production line setup is gaining traction among eco-conscious farmers and entrepreneurs—and for good reason.This process uses earthworms to break down organic materials and produce nutrient-rich worm castings, which are highly beneficial for soil health and plant growth.

1.Why Vermicompost Production Line Setup Stands Out

Unlike chemical fertilizers or even traditional composting, vermicompost production line setup relies on nature’s own workers: earthworms. These tiny creatures break down organic matter like food scraps, crop residues, and manure into a substance that’s rich in humus, enzymes, and beneficial microbes. The result? A fertilizer that doesn’t just feed plants but improves soil structure over time, making it ideal for organic farms, home gardens, and even greenhouse operations.

What makes vermicompost production line setup special is its efficiency. Worms work 24/7, processing waste much faster than standard compost piles. Plus, the production line can be tailored to fit your space—from a compact setup in a warehouse to a larger facility with automated systems. It’s also low-energy: no need for heavy machinery or high temperatures, just controlled environments where worms thrive.

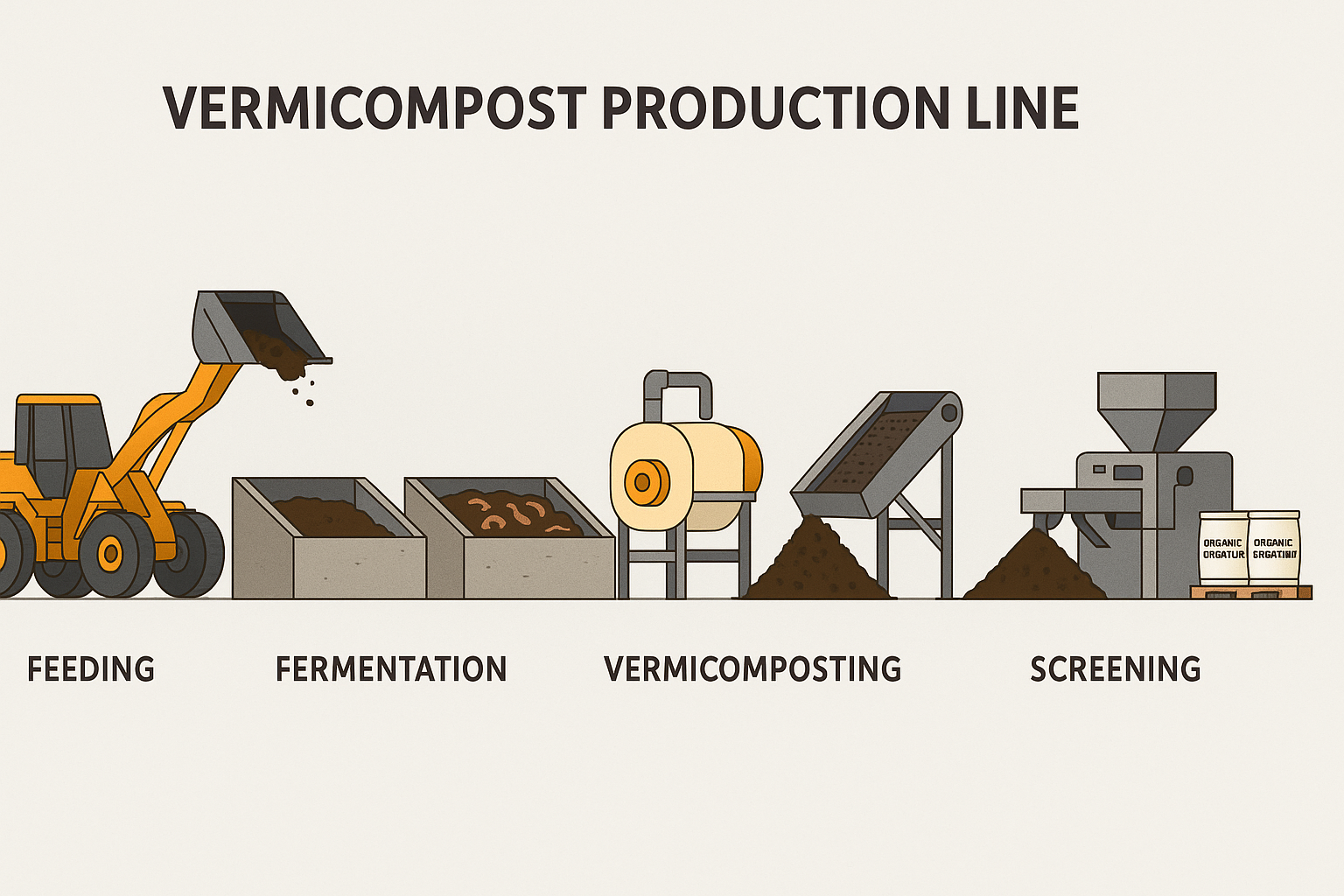

2.Main Components of a Vermicompost Production Line Setup

(1) Raw Material Pretreatment

Before earthworms can process the organic waste, the materials—such as livestock manure, food scraps, crop residues, and kitchen waste—must be pre-composted. This initial aerobic fermentation step helps reduce pathogens, balance pH, and prepare a suitable substrate.

(2) Vermiculture Beds or Units

Pre-composted materials are transferred to long worm beds or customized worm composting units. Earthworms (usually Eisenia fetida or red wigglers) are introduced to begin the digestion process. Proper moisture (around 70–80%) and temperature (15–30°C) are maintained to create ideal living conditions for the worms.

(3) Feeding and Maintenance

Feeding is done regularly, ensuring new organic matter is layered on top while older material continues to be processed. The vermicomposting stage may take 30–60 days depending on temperature, feedstock, and worm population.

(4) Castings Collection and Screening

After the vermicomposting cycle, worm castings are harvested and separated from the worms. A vibrating screen or rotary drum screener is used to remove impurities and obtain fine, uniform vermicompost granules.

(5) Drying and Packaging

Moisture levels are further reduced using natural or mechanical drying methods. The final product is packed using automatic packaging machines, ready for distribution as organic fertilizer.

3.Why Choose a Professional Vermicompost Line Setup?

While traditional vermicomposting is low-cost, it’s also labor-intensive and hard to scale. A professional vermicompost production line setup ensures:

Hygiene: Pathogens and odor are controlled effectively

Efficiency: Less manual work, faster processing time

Quality Control: Uniform, screened product with consistent nutrient levels

Better Returns: Higher productivity and faster ROI

LANE provides turnkey solutions with expert support, machine customization, and installation guidance to help clients start vermicompost production quickly and sustainably.

4.Scaling Vermicompost Production Line Setup for Business

If you’re considering vermicompost production line setup as a business, there’s plenty of demand to meet. Organic farmers are willing to pay a premium for high-quality vermicompost, and garden centers often struggle to keep it in stock. To scale, look into automated feeding systems that deliver waste to worm beds on a schedule, or conveyor belts that move finished castings to packaging stations.

You can also diversify by selling worm eggs (cocoons) to other growers or offering workshops on small-scale vermicomposting. Many operators partner with local restaurants or grocery stores to source organic waste, turning their “trash” into your raw material—and creating a closed-loop system that customers love.

Vermicompost production line setup isn’t just about making fertilizer; it’s about building a sustainable cycle that benefits the planet and your bottom line. With the right setup, you can turn waste into a valuable product while contributing to greener agriculture. Whether you’re a farmer looking to cut costs or an entrepreneur chasing a new venture, vermicompost production line setup is worth exploring.

As demand for organic fertilizers grows, setting up a vermicompost production line is a strategic and sustainable business move. By turning agricultural and kitchen waste into valuable worm castings, businesses and farms can reduce their environmental impact while generating economic returns.If you’re considering investing in a vermicompost production system, reach out to LANE for expert advice and complete production solutions tailored to your needs.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520