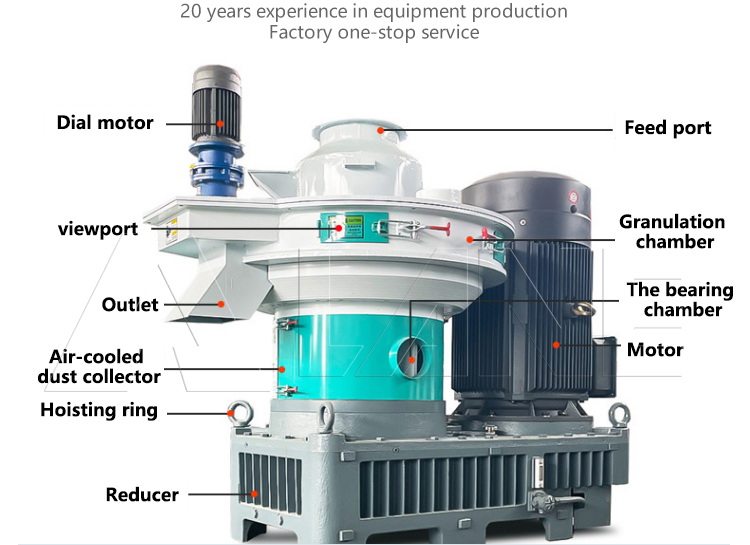

Being one energy saving type professional biomass pellet machine, vertical ring die pellet machine get its name from the vertical ring die that is beneficial for working parts during pelleting process. This type of wood pellet machine is especially suitable for large and medium pellet production manufacturer.

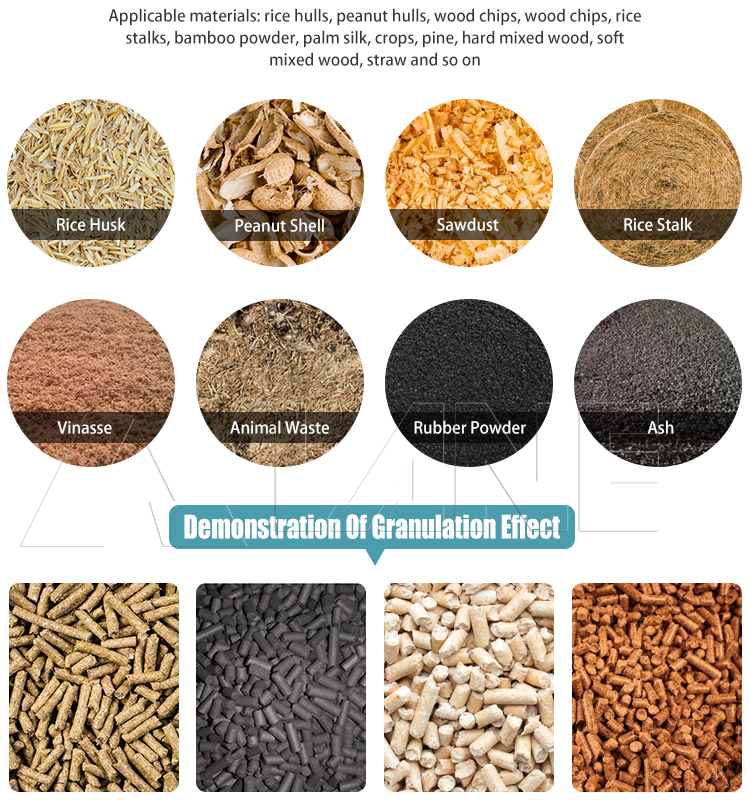

Vertical Ring die pellet machine is roller driven type and combines advantages of flat die pellet mill and ring die pellet mill. It can be adopted to process wide range of biomass materials such as wood chips, straw, sawdust, rice husk, peanut shell, chaff, bamboo shavings, bagasse, alfalfa, palm kernel shell, etc.

Vertical Ring Die Pellet Machine |

|||||

|---|---|---|---|---|---|

| Model | LA-PM2 | LA-PM3 | LA-PM6 | LA-PM8 | LA-PM10 |

| Output designed(kg/h) | 700-1000 | 1000-1500 | 1500-2000 | 2000-2500 | 2500-3000 |

| Power(kw) | 55 | 75 | 90-110 | 132 | 160 |

| Dimensions(mm) | 2133*920*1389 | 2400*1300*1800 | 1800*1100*1700 | 1800*1100*1700 | 2590*1690*1890 |

| Weight(kg) | 2586 | 2908 | 3780 | 5600 | 7500 |

| Die inner diameter(mm) | 508 | 508 | 510 | 630 | 660 |

| Pellet diameter(mm) | 8-9 | 8-9 | 8-9 | 8-12 | 8-12 |

| Pellet forming rate | 98% | 98% | 98% | 98% | 98% |

| Pellet length(mm) | 10-50 | 10-50 | 10-50 | 10-50 | 10-50 |

| Moisture of raw material | 13-17% | 13-17% | 13-20% | 13-20% | 13-20% |

1. The ring die rotates under the drive of the motor, and the material enters the granulation room and is taken into the working area;

2. The pressure roller also begins to rotate with the help of friction in the working area, and the material moves forward faster;

3. The extrusion force and the density of the material gradually increase, when the extrusion force is greater than the friction between the material and the inner wall in the mold hole, the material is squeezed into the ring die hole;

4. The material is continuously squeezed into the ring die hole, and after forming, it is pressed out and cut off by the cutter to form a granular feed.

Characteristics of Vertical Ring Die Pellet Machine

1.Feeding vertically, raw materials with no arching, easy for heating dissipation.

2.Key parts adopts superior alloy steel with heat treatment by German vacuum furnace, which together prolongs its service life by 5-7 times.

3.High precision gears with automatic lubricant pump system makes the gearbox has stable working condition.

4.Independent and frequency changeable cutting device make the machine has high pelletizing rate.

5.Ring die with different pore diameters for customer to choose, long service life, high quality, pellets with smooth surface.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales2@lanesvc.com

Contact number: +86 15515885328

Whatsapp: +86 15515885328

World-class and Energy-saving Operation, Factory Price & Fast Delivery.