When planning a fertilizer production line, many manufacturers struggle with the decision of whether they should choose a disc granulator or select a teeth (stirring) granulator instead. Both machines can produce fertilizer granules, but their performance, maintenance requirements, and long-term operating costs differ significantly. Many producers, after comparing real production data, discover that the disc design provides advantages in efficiency, quality, stability, and cost control. These benefits often turn an ordinary equipment purchase into a long-term strategic choice.

So why do so many manufacturers ultimately decide to choose a disc granulator? And what allows the disc structure to consistently outperform a teeth granulator in practical operations? Understanding the engineering principles behind each machine helps reveal why the disc type has become increasingly popular among fertilizer producers worldwide.

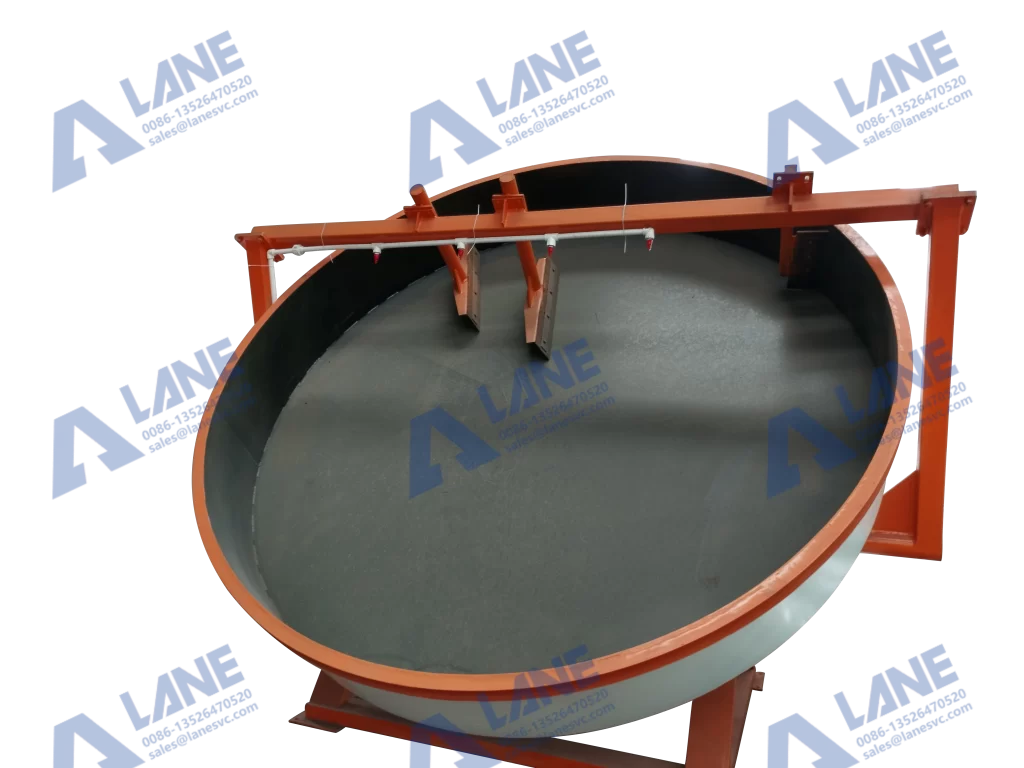

One major reason factories choose a disc granulator is its exceptional level of process visibility. Operators can directly observe the materials as they roll, compact, and form into granules. This visibility is especially useful when working with materials that vary in moisture, fiber content, or density. Being able to see the granulation behavior allows operators to respond quickly—adding moisture, adjusting spray angles, modifying feed rates, or correcting material distribution.

In contrast, the teeth granulator is a closed machine. Inside, high-speed stirring teeth operate at high intensity, and operators must rely on indirect measurements or experience to judge whether the material is forming properly. Troubleshooting becomes harder and less predictable. For new operators, the learning curve is significantly steeper. This is why many experienced engineers prefer an open-type disc structure: it simply gives them better control and more confidence.

Energy consumption has become an increasingly important factor in fertilizer production. Electricity costs continue to rise globally, and environmental regulations often require factories to reduce their overall energy footprint. Many producers choose a disc granulator because it naturally consumes less power. The disc rotates at a relatively low speed, relying on gravity, friction, and natural rolling force to form granules.

A stirring pin granulator, by contrast, relies on high-speed inner shafts and stirring teeth. The mechanical resistance is high, and the energy load increases sharply with sticky or high-moisture materials. This results in higher heat generation, increased wear, and greater mechanical stress. For factories operating 24 hours a day, the long-term difference in electricity bills can be substantial.

Beyond energy savings, lower operating speeds mean the machine experiences less vibration and mechanical fatigue. This contributes directly to longer service life and reduced long-term depreciation.

Another common reason to choose a disc granulator is its low maintenance requirement. The machine has a simple structure with fewer fast-moving parts. This simplicity reduces mechanical failures and the need for frequent adjustment. Routine maintenance mainly involves checking the reducer, lubricating bearings, and inspecting the disc scraper.

By contrast, teeth granulators contain multiple rotating teeth, wear plates, liners, and shafts. These components face constant impact and friction. They wear quickly, especially when processing abrasive raw materials such as mineral powders or semi-dry organic matter. Replacing parts becomes a routine expense—and downtime extends production cycles and reduces output.

Factories that depend on stable operation, such as large fertilizer enterprises or continuous production lines, benefit significantly from the simpler structure and lower maintenance burden of a disc system.

A well-adjusted disc granulator can achieve granulation rates above 90%. This is because granules grow through natural layering—small seeds roll inside the disc and gradually accumulate material. The formation process is gentle, controlled, and predictable, resulting in high hardness and uniform size.

A teeth granulator creates granules through intense mechanical mixing. The environment is more turbulent, and the granules face more collisions and shear forces. This often produces more fine powder and increases the return-to-crusher ratio. Higher recycle rates mean higher material circulation, greater energy consumption, and more wear on downstream machines.

This stability explains why many plants that require controlled granule size distribution prefer to choose a disc granulator for key sections of their production lines.

Because the disc structure is intuitive, operators quickly learn how to manage it. Training new workers is easier, and daily tasks such as cleaning, inspection, and lubrication require minimal technical expertise. This reduces labor costs and lowers the probability of operational errors.

With a stirring pin granulator, operators must understand internal mechanical structure, clearance adjustment, shaft alignment, and wear compensation—skills that require more experience and technical training. For factories with frequent staff rotation, relying on such a specialized machine can be challenging.

A simpler operation model also contributes to safer working conditions. Workers can observe the disc at a distance and avoid entering confined areas during daily checks.

Many producers handle a wide variety of raw materials: chicken manure, cow manure, pig manure, humic acid, bentonite, phosphorus powder, NPK raw materials, and compost mixtures. Material characteristics can change from batch to batch due to weather, storage time, or moisture differences. This is where adaptability becomes critical.

A disc granulator handles these variations well. Even materials with inconsistent moisture or viscosity can still form granules through natural rolling. This wide adaptability is one of the key reasons many factories eventually decide to choose a disc granulator.

Stirring pin granulators, however, often struggle with sticky or fibrous materials. They may clog, overload, or produce irregular granules. This inconsistency leads to unnecessary downtime and material loss.

Large fertilizer plants rely on predictable, stable, and scalable equipment. Any breakdown affects not only output, but also workers, logistics, and downstream processing steps. The disc’s simple mechanics make it easy to integrate with drying systems, screening machines, conveyors, and coating machines.

Its reliability allows manufacturers to run long production cycles without major interruptions. For this reason, medium and large NPK or organic fertilizer plants often integrate multiple discs into a single production flow, creating a stable and efficient granulation section.

For over two decades, LANE has specialized in fertilizer machinery manufacturing in China. Many clients around the world trust LANE equipment because of its engineering knowledge, strict quality control, and comprehensive after-sales support.

LANE provides:

Customized fertilizer production line design

Professional engineering and technical consulting

Installation and commissioning services

Complete after-sales system, including troubleshooting and upgrades

ISO 9001 and CE-certified manufacturing standards

This level of technical support ensures that the machine you select—especially when you choose a disc granulator—operates with maximum efficiency and minimum downtime. LANE’s expertise reduces risks, increases productivity, and ensures that equipment is optimized for long-term performance.

When comparing maintenance costs, granule quality, energy consumption, adaptability, operator learning curve, and long-term stability, most producers ultimately decide to choose a disc granulator because it offers the highest economic and operational value. It achieves a balance between simplicity and performance that few other granulation technologies can match.

For fertilizer manufacturers seeking a reliable, efficient, and cost-effective solution, the advantages of the disc design are clear—and often decisive.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520