Rotary drum cooler/dryer is a commonly used equipment in fertilizer production lines, mainly used for cooling and drying fertilizer products. Rotary drum cooler/dryer has been widely used in the field of material cooling due to its uniform cooling, high efficiency and energy saving, and easy operation.

Lane can customize a dedicated rotary drum cooler/dryer for you to meet any of your needs.

Rotary drum cooler/dryer |

||||||

|---|---|---|---|---|---|---|

| Model | Capacity(tph) | Drum Size(mm) | Rotation speed(r/min) | Steel Plate Thickness(mm) | Lift Plate Thickness(mm) | Power(kw) |

| LARC0808 | 1-2 | Ф800*800 | 5 | 8 | 4 | 5.5 |

| LARC1010 | 2-3 | Ф1000*1000 | 5 | 10 | 6 | 5.5 |

| LARC1212 | 3-5 | Ф1200*1200 | 5 | 10 | 6 | 7.5 |

| LARC1515 | 5-8 | Ф1500*1500 | 5 | 12 | 6 | 15 |

| LARC1616 | 8-12 | Ф1600*1600 | 5 | 12 | 6 | 18.5 |

| LARC1818 | 12-15 | Ф1800*1800 | 4 | 14 | 6 | 22 |

| LARC2020 | 20-25 | Ф2000*2000 | 4 | 14 | 6 | 37 |

| LARC2222 | 25-30 | Ф2200*2200 | 4 | 16 | 6 | 37 |

| LARC2424 | 30-35 | Ф2400*2400 | 4 | 16 | 6 | 45 |

| LARC2626 | 35-40 | Ф2600*2600 | 3 | 18 | 6 | 55 |

| LARC2828 | 40-45 | Ф2800*2800 | 3 | 18 | 6 | 75 |

| LARC3028 | 45-50 | Ф3000*3000 | 3 | 18 | 6 | 90 |

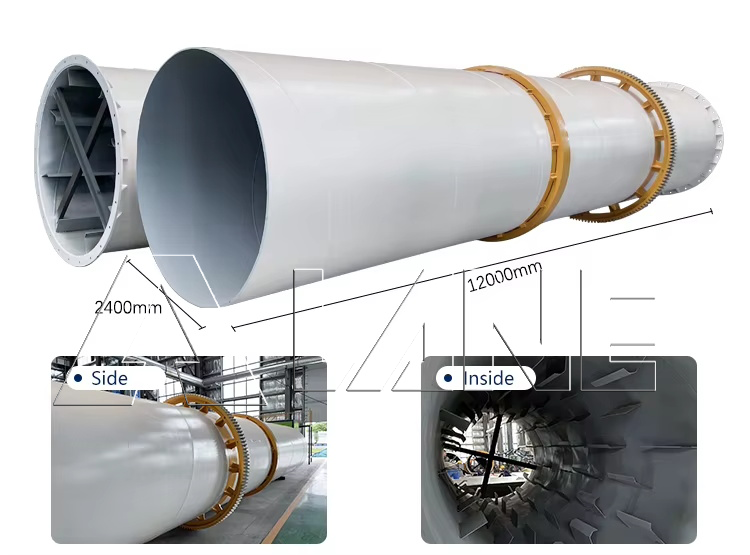

When therotary drum cooler/dryer is working, the dry wet material is sent to the hopper by a belt conveyor or a bucket elevator, and then enters the feeding end through the feeding pipe of the hopper feeder. The inclination of the feeding pipe should be greater than the natural inclination of the material so that the material can flow smoothly into the cylinder.

The cylinder of the rotary drum cooler/dryer is a rotating cylinder slightly inclined to the horizontal line. The material is added from the higher end, and the heat carrier flows out from the lower end, contacting the material in countercurrent, and the heat carrier and the material also flow into the cylinder together. As the cylinder rotates, the material moves to the lower end under the action of gravity.

During the forward movement of the wet material in the cylinder, it directly or indirectly obtains heat from the heat carrier, so that the hot material can be cooled and dried, and then sent out at the discharge end through a belt conveyor or a screw conveyor.

A shoveling plate is installed on the inner wall of the cylinder. Its function is to scoop up and scatter the material, so that the contact surface between the material and the airflow is increased to increase the cooling and drying rate and promote the advancement of the material.

For more information, please contact us by sending an inquiry today! We can help you!

Uniform cooling

Through the rotation of the drum and the action of the internal guide plate, the material is constantly turned and mixed, so that each particle can be fully cooled to avoid local overheating or overcooling.

High efficiency and energy saving

The use of advanced cooling technology can quickly and effectively reduce the temperature of the material, which not only improves production efficiency but also reduces energy consumption.

Simple operation

The operating interface of the rotary drum cooler/dryer is intuitive and easy to understand, which is convenient for users to quickly get started, and maintenance is relatively simple, which reduces operating costs.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.