In recent years, the 10t/h soybean meal organic fertilizer production line has become an important solution in modern agriculture. As people care more about soil health and environmental protection, organic fertilizer is no longer a new idea. This production line helps turn soybean meal into useful fertilizer in an efficient and stable way. It connects technology with real farming needs and shows how agriculture is changing step by step.

This production line is not only about machines. It is about using resources wisely and protecting the future of farming.

The demand for organic fertilizer is growing every year. Many countries are limiting the use of chemical fertilizer because it can damage soil in the long term. Organic fertilizer improves soil structure and supports healthy crop growth.

The 10t/h soybean meal organic fertilizer production line fits this market trend very well. Soybean meal comes from soybean oil production and is easy to find. It contains rich organic matter and nutrients. By using it as raw material, producers can lower costs and increase value.

A capacity of 10 tons per hour is very suitable for commercial production. It is large enough to meet market demand but still easy to manage. This balance makes the production line attractive to investors and fertilizer plants. Because of these reasons, the market outlook is stable and positive.

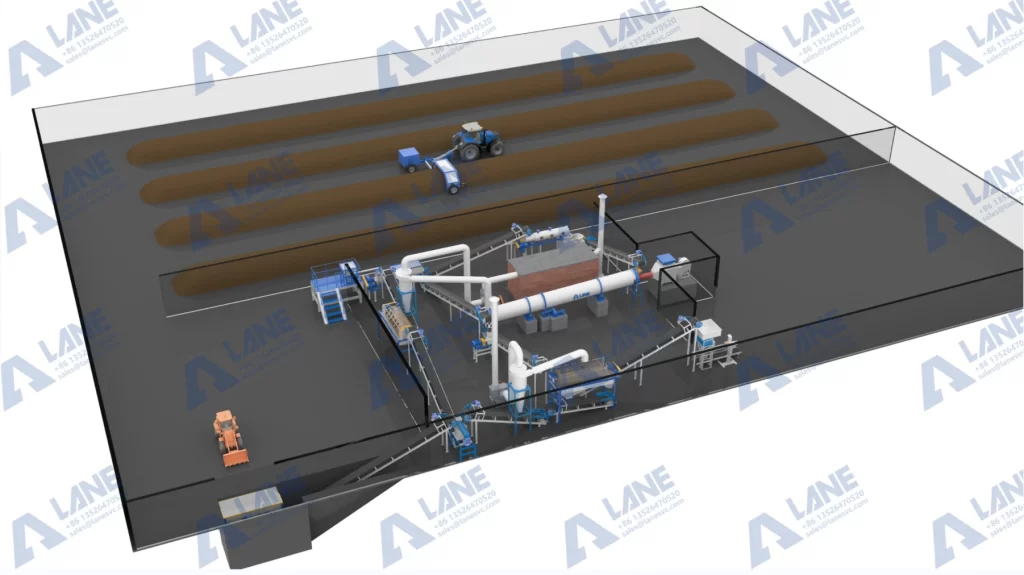

The 10t/h soybean meal organic fertilizer production line is designed as a complete system. Each step connects smoothly with the next one. The main process includes raw material crushing, mixing, fermentation, granulation, drying, cooling, and packaging.

The goal of this design is simple. Raw materials enter the line, and finished fertilizer comes out at the end. The whole process focuses on efficiency, stability, and easy operation. Automation systems help reduce manual work and improve safety.

The first step is crushing. Raw soybean meal may have different sizes and shapes. Crushing helps make the material uniform.

In the 10t/h soybean meal organic fertilizer production line, a vertical crusher is often used. Materials enter from the top and are broken by high-speed rotating blades. After crushing, the material falls down naturally.

This machine takes little space and works smoothly. It handles moist materials well and produces even particles. Good crushing makes later steps easier and improves final product quality.

After crushing, materials go into the mixing system. Mixing is very important because nutrients must be evenly distributed.

The mixer in the 10t/h soybean meal organic fertilizer production line works in a simple and effective way. Different raw materials and additives are blended together. The mixing time can be adjusted based on formula needs.

Even mixing helps ensure that every fertilizer pellet has similar nutrient content. This improves fertilizer performance in the field and builds trust with users.

Fermentation is the core step of organic fertilizer production. It allows microorganisms to break down organic matter.

In the 10t/h soybean meal organic fertilizer production line, fermentation equipment provides proper temperature and air flow. This helps kill harmful bacteria and improve nutrient availability.

After fermentation, the material becomes more stable and safer for crops. This step also reduces odor and improves fertilizer quality.

Granulation gives fertilizer its final shape. Granules are easier to store, transport, and apply.

The disc granulator in the 10t/h soybean meal organic fertilizer production line forms uniform pellets. The size of the granules can be adjusted based on customer needs.

Good granulation improves product appearance and market competitiveness. It also helps fertilizer dissolve evenly in the soil.

After granulation, fertilizer pellets may still contain moisture. Drying removes excess water and improves shelf life.

In the 10t/h soybean meal organic fertilizer production line, the dryer works together with a cooling machine. Drying improves strength, and cooling prevents pellets from sticking together.

This system helps ensure that the fertilizer remains stable during storage and transport.

The final step is packaging. Clean and accurate packaging improves product image.

The packaging system of the 10t/h soybean meal organic fertilizer production line can be manual or automatic. Bag weight can be adjusted based on market needs.

Well-packed fertilizer is easier to sell and transport. It also shows professionalism and quality.

At LANE, our company has more than 20 years of experience in fertilizer machinery manufacturing. We design and supply complete solutions, including the 10t/h soybean meal organic fertilizer production line, based on customer needs.

We follow ISO9001 and CE international quality standards. Our professional engineering team supports design, manufacturing, installation, and after-sales service. At LANE, we believe real value comes from long-term cooperation and reliable support.

In daily operation, the 10t/h soybean meal organic fertilizer production line runs smoothly. Operators can control the system through simple panels. Automatic systems reduce labor intensity and human error.

The production line is suitable for continuous operation. Stable output and consistent quality help producers plan production and sales more easily.

The future of the 10t/h soybean meal organic fertilizer production line is promising. Smart control systems and data monitoring will become more common. Energy-saving designs will help reduce costs.

Organic fertilizer will play a bigger role in sustainable agriculture. Production lines like this will support greener farming and better soil management. From a student’s view, this makes agriculture feel modern and full of hope.

The 10t/h soybean meal organic fertilizer production line is a complete and practical solution for organic fertilizer production. It combines stable technology, clear process design, and reliable equipment. By turning soybean meal into valuable fertilizer, it supports both economic growth and environmental protection.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520