In today’s world, where sustainability is no longer just a trend but a necessity, Agricultural waste composting production lines offer an innovative solution to organic waste management. These systems convert agricultural residues into high-quality compost, promoting eco-friendly farming practices and addressing significant environmental concerns, such as soil degradation and overuse of chemical fertilizers. By investing in these advanced systems, farmers and agribusinesses are not just managing waste but also creating valuable resources for their farms and the environment.

Modern agricultural waste composting production line represent a revolution in waste management. Far from simply disposing of agricultural waste, these systems turn what was once seen as trash into valuable black gold – nutrient-rich compost that can significantly improve soil health and crop yields. This transformation is essential for sustainable farming, as it closes the loop of organic waste and supports the creation of a more eco-friendly agricultural process.

In a time when concerns over environmental pollution, soil degradation, and the harmful effects of chemical fertilizers are on the rise, agricultural waste composting production lines offer a solution that not only helps farmers reduce waste but also enhances the quality of soil and promotes long-term sustainability.

With growing demand for organic produce and a growing emphasis on sustainable agricultural practices worldwide, agricultural waste composting production line is becoming a priority. These systems help recycle waste into organic fertilizer, minimizing environmental impact while improving soil fertility. Given the increasing pressure to reduce carbon footprints and achieve sustainable agricultural practices, many farmers now view these systems as an essential investment. As more and more businesses incorporate organic waste recycling into their core practices, agricultural waste composting production lines are becoming standard equipment on farms of all sizes. These systems not only aid in waste management but also actively contribute to the health of the planet and crops.

Our systems process virtually all types of agricultural organic matter. Here’s a breakdown of the most valuable input materials:

| Waste Category | Key Examples | Nutrient Profile | Processing Tips |

|---|---|---|---|

| Animal Manures | Cattle, poultry, swine, sheep | High nitrogen | Mix with carbon-rich materials |

| Crop Residues | Corn stalks, rice husks, wheat straw | High carbon | Requires shredding for fast breakdown |

| Food Processing Waste | Fruit/vegetable peels, brewery grains | Balanced nutrients | Excellent for rapid composting |

| Aquatic Biomass | Algae, water hyacinth | Rich in micronutrients | Effective moisture regulator |

| Agro-Industrial Waste | Cotton gin trash, sugarcane bagasse | Fibrous structure | Benefits from microbial inoculants |

Pro Tip: The ideal carbon-to-nitrogen ratio for efficient composting is 25-30:1. Our LANE Smart Mixing Systems automatically optimize this balance for perfect decomposition.

3.The Science Behind Agricultural Waste Composting Production Line

At its core, the agricultural waste composting production line utilizes the natural decomposition process and optimizes it through controlled conditions. This system provides an ideal environment for microorganisms, enabling them to efficiently decompose organic matter and thereby generate stable humus rich in nutrients and beneficial microorganisms.

A complete agricultural waste composting production line consists of several integrated machines, each playing a critical role in ensuring the efficiency, consistency, and quality of the composting process.

(1) Material pretreatment system

Before composting begins, agricultural waste needs to be pretreated to optimize the decomposition process. Large materials such as straw, corn stalks, and rice husks can be reduced in size using a vertical shaft crusher. This increases the surface area for microbial activity, which speeds up the decomposition process.

For high-moisture materials such as animal manure or food waste, a inclined dewatering machine can be added. This system is usually a solid-liquid separator that is used to adjust the moisture content to the ideal fermentation level (usually between 50% and 60%). If the moisture content is not appropriate, the composting process may be inefficient, resulting in poor quality compost.

(2) Mixing equipment

The next step in the process is to mix the various raw materials to ensure the ideal carbon-nitrogen ratio (C/N). The proper C/N ratio is essential for the microbial activity required to effectively decompose organic matter. In some cases, microbial inoculants or compost starters can be added to speed up the process.

(3) Fermentation and compost turning system

One of the most critical components of an agricultural waste composting line is the fermentation system. Various types of compost turning machines such as crawler type compost turner, wheeled compost turner or groove type compost turner play a key role here. These machines turn the compost regularly to provide oxygen, regulate temperature and ensure uniform decomposition.

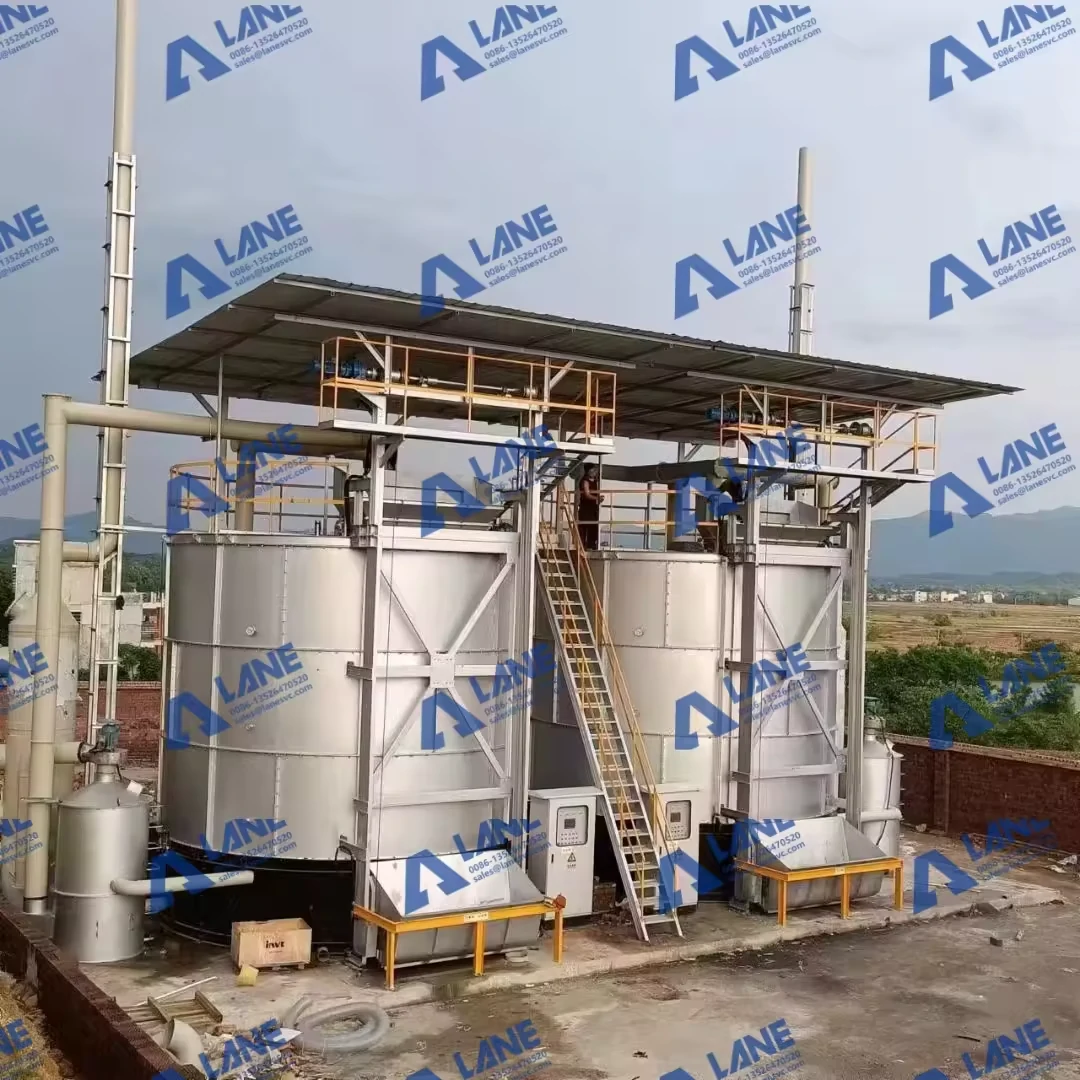

In some systems, vertical fermentation tanks are used to control temperature and airflow to create ideal conditions for composting. These closed or temperature-controlled systems are particularly suitable in areas with strict environmental regulations and help to obtain stable, high-quality compost.

(4) Compost Maturation Zone After active fermentation, the compost enters the maturation stage, where it solidifies and stabilizes. During this stage, the compost becomes more stable, improves its nutrient content, and reduces the risk of phytotoxicity (plant damage caused by immature compost). This step is crucial to ensuring the safety of the compost for agricultural applications.

(5) Rotary Screener

After the compost matures, it passes through a rotary screener to separate the fine, fully decomposed compost from larger, undecomposed particles or foreign matter. This ensures that the final product is of uniform quality and free of contaminants, ready for packaging and use.

(6) Automated Packaging System

The final step in the process is the packaging of the compost. An automatic packaging machine fills, weighs, and seals the compost into bags of various sizes (e.g., 25 kg or 50 kg). For large-scale distribution, the system can be connected to a palletizer and packaging machine to simplify packaging and logistics.

Together, these components form a seamless, efficient system that converts agricultural waste into a high-quality, market-ready product that benefits both the farmer and the environment.

The agricultural waste composting production line is poised for continued innovation as technology evolves. The future of agricultural waste composting production line is focused on greater efficiency, sustainability, and integration with renewable energy sources, making it a more eco-friendly and economically viable solution for organic waste management.

(1) Hyper-Localized Composting Networks

Emerging distributed models are transforming how composting systems operate, making them more accessible for farms of all sizes and even for urban environments.

Micro-Composting Hubs: These containerized, automated units are designed to serve individual farms or urban neighborhoods. With capacities under 1 ton/day, they allow for on-site processing of agricultural waste, reducing transportation costs and providing immediate access to fresh compost.

On-Demand Mobile Units: Mounted on trucks, these mobile composting systems travel between multiple farms or facilities. They are ideal for seasonal agricultural operations, where composting needs fluctuate throughout the year.

Community-Scale Biofactories: These integrated facilities combine composting with other sustainable production systems such as mushroom cultivation, insect farming for animal feed, and bioenergy generation. This approach creates a multi-purpose waste recycling hub that maximizes the value of agricultural residues.

By implementing localized composting networks, farmers can reduce carbon footprints, improve operational flexibility, and accelerate the composting process without relying solely on large centralized plants.

(2) Hybrid Energy-Recovery Systems

The next generation of the agricultural waste composting production line is evolving into energy-positive systems that do more than recycle waste—they also generate renewable energy.

Thermoelectric Conversion: By capturing excess heat from the composting process and converting it into electricity, composting systems can partially power themselves, lowering operational costs.

Volatile Organic Compound (VOC) Harvesting: Modern composting units can capture methane and other gases released during decomposition. These gases can then be converted into bioenergy, reducing greenhouse gas emissions and generating additional value.

Integrated Algae Cultivation: Compost leachate, rich in nutrients, can be used as a feed source for cultivating high-value algae biomass. This algae can be processed into biofuels, animal feed supplements, or agricultural biostimulants.

By merging waste recycling with renewable energy generation, composting lines will become central components of sustainable farm energy systems.

(3) Space-Efficient Vertical Composting

With the rapid growth of urban agriculture and the increasing cost of farmland, space-efficient agricultural waste composting production lines are becoming essential for both city-based and small-scale operations.

Tower Reactor Systems: Multi-story composting units use gravity-fed material flow, allowing facilities to reduce their footprint by up to 80% while maintaining high processing capacity.

Modular Wall Systems: Composting panels integrated into building facades can process organic waste while doubling as vertical gardens, making them perfect for urban farms and community green projects.

Underground Composting Systems: Automated subterranean units process waste below ground level, with surface-level access points for easy waste input and compost retrieval. These systems are ideal for space-constrained areas where above-ground equipment is impractical.

As the agricultural industry faces increasing pressure to adopt sustainable agricultural practices,the agricultural waste composting peoduction line offers a viable solution to manage organic waste while promoting soil health. By converting waste into a valuable resource, these systems provide farmers with high-quality organic fertilizer that improves soil structure, promotes plant growth, and reduces reliance on chemical fertilizers.Incorporating composting systems into modern agricultural practices also contributes to the broader goals of reducing carbon footprint and promoting environmentally friendly agricultural practices. As more farmers adopt agricultural waste composting production lines, they will contribute to building a more circular and sustainable agricultural ecosystem.

To sum up,the modern agricultural waste composting production line represents far more than just a waste management solution – it’s a fundamental component of the transition to regenerative farming practices. By converting waste, which was previously considered a problem to be dealt with, into valuable resources, these systems not only generate economic value but also address significant environmental issues.

As technology advances and awareness grows, we can expect to see agricultural waste composting production lines become standard equipment on farms of all sizes. The combination of environmental benefits, cost savings, and new revenue opportunities makes this an investment that pays dividends across multiple dimensions.

For agricultural operators who want to improve sustainability and increase profitability, implementing an agricultural waste composting line is one of the most practical and effective solutions available today. The future of agriculture lies not only in growing crops, but also in improving soil health, and advanced composting systems are the tools to achieve this goal.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520