Walk through almost any farming area after harvest, and you will see piles of straw, husks, stalks, and manure. For years, these materials were seen as a burden. Today, an agricultural waste conversion system is giving them a new role. Instead of being burned or dumped, farm waste is processed, reused, and sent right back into the fields in a more valuable form.

This shift is not about complicated science. It is about smart machines working together. An agricultural waste conversion system uses a clear, step-by-step process to turn loose, messy waste into neat, easy-to-use pellets. These pellets can be organic fertilizer, soil conditioners, or even energy fuel, helping farms save money and protect the environment at the same time.

The journey starts on the farm. After crops are harvested, materials like straw, corn stalks, rice husks, and animal manure are collected. On their own, these materials are bulky and hard to manage. This is where an agricultural waste conversion system begins to show its value.

The first key machines are hammer crushers. These machines break large pieces of waste into smaller, even sizes. Long straw becomes short fibers. Hard clumps of manure are loosened. This step may sound simple, but it is important. Even-sized material moves smoothly through the next machines and helps the final pellets hold their shape.

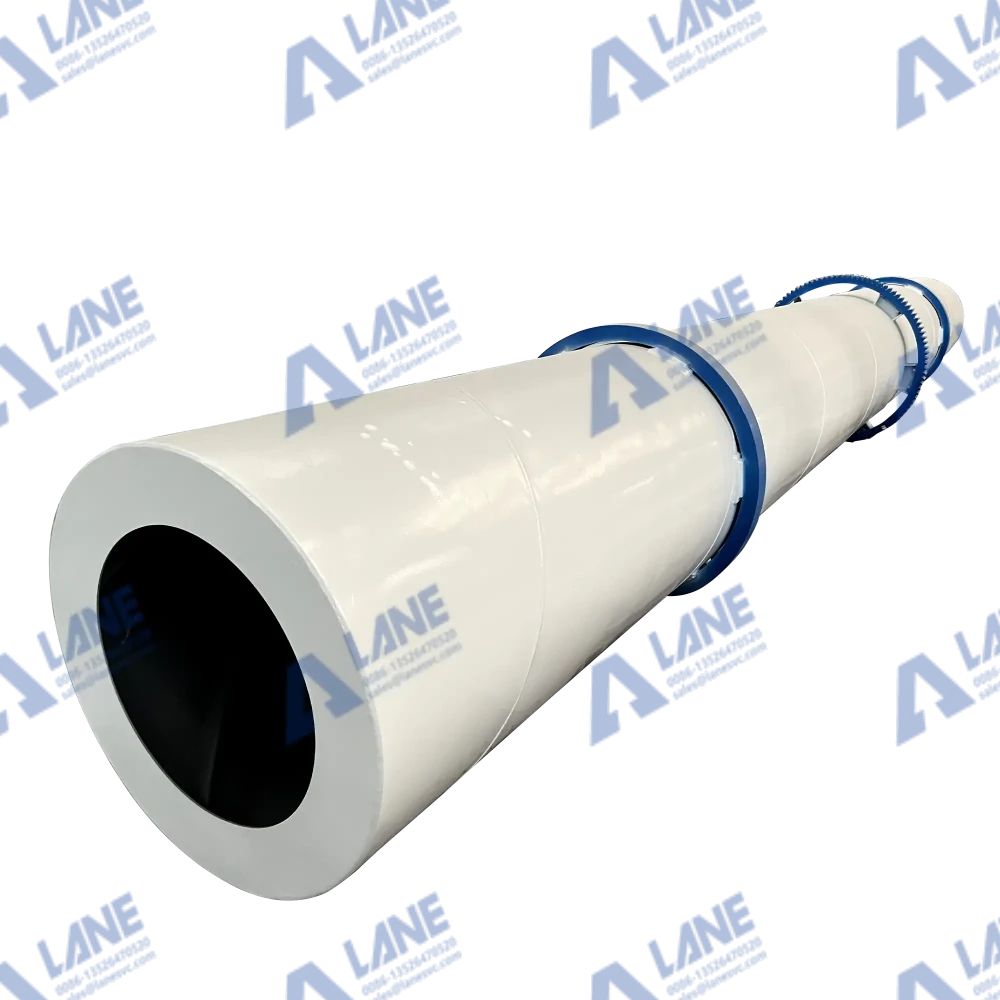

After crushing, moisture control becomes the focus. Many types of agricultural waste are too wet. If moisture is too high, pellets will not form properly. In a complete agricultural waste conversion system, a rotary drum dryer is used to reduce moisture to the right level.

The rotary drum dryer removes water without damaging nutrients. At the same time, a horizontal fertilizer mixer blends different materials together. For example, straw can be mixed with manure to balance nutrients. This blended material is more valuable once it becomes fertilizer.

The heart of the process is the organic fertilizer granulator. Inside an agricultural waste conversion system, this machine applies pressure to the prepared material. As it passes through small holes in a die, the material forms dense, uniform pellets.

Granulators are powerful but easy to understand. Rollers press the material, heat builds naturally from friction, and pellets come out ready to cool. These pellets are easier to store, transport, and spread on fields. Farmers can use them with standard equipment, saving time and labor.

Fresh pellets are warm and slightly soft. A rotary drum cooler lowers their temperature and hardens them. A rotary screening machine then removes broken pieces, sending them back for reprocessing. In a well-designed agricultural waste conversion system, nothing is wasted.

Finally, an automatic fertilizer packing machine weighs and bags the pellets. Whether the pellets are used on the same farm or sold to others, they are clean, stable, and professional-looking. What was once waste is now a product with real value.

Pellets produced by an agricultural waste conversion system feed the soil in a steady way. Organic fertilizer pellets release nutrients slowly. This improves soil structure, supports healthy microbes, and helps crops grow stronger roots.

Farmers also benefit economically. They reduce disposal costs and cut spending on chemical fertilizers. Some farms even create a new income stream by selling excess pellets. This closed-loop approach keeps resources on the farm and reduces environmental impact.

At LANE, we have spent over 20 years working in fertilizer machinery manufacturing. We have seen firsthand how an agricultural waste conversion system can change farm operations for the better. Our experience helps us understand both the machines and the real needs of farmers.

We design and build complete production lines for organic fertilizer, compound fertilizer, and liquid fertilizer. Our professional engineering team works closely with customers. We listen, plan, customize, and then manufacture equipment that fits each project. From layout design to on-site installation, we stay involved at every step of the agricultural waste conversion system.

Quality matters in agriculture. Our machines meet ISO9001 and CE standards, giving customers confidence in safety and performance. But machines alone are not enough. We provide one-stop service, including training, maintenance, troubleshooting, and upgrades. We want every agricultural waste conversion system we deliver to run smoothly for years.

Our goal is simple. We help farms turn waste into something useful. We help reduce pollution and improve soil health. And we help customers build reliable production lines that grow along with their business.

As agriculture faces pressure to become greener and more efficient, solutions like an agricultural waste conversion system will play a bigger role. With the right machines and the right partner, farm waste is no longer a problem. It is a resource waiting to be used.

Turning leftovers into pellets is not just a technical process. It is a practical step toward smarter farming, healthier soil, and a more sustainable future.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520