In the pet care world, performance and consistency matter more than ever, and that starts long before a product reaches a cat’s litter box. A modern bentonite cat litter production line is where raw mineral turns into a clean, reliable, clumping product that pet owners trust. By carefully selecting the right machine for each processing stage, manufacturers can achieve stable quality, high efficiency, and smooth daily operation without unnecessary complexity.

At LANE, we see this process not as a rigid industrial routine, but as a well-orchestrated journey. Each step builds on the previous one, and every machine plays a clear role in shaping the final result of the bentonite cat litter production line.

The structure of a complete bentonite cat litter production line follows a straightforward logic: prepare the raw clay, form strong granules, stabilize them, and package them cleanly. Instead of overcomplicating the setup, choosing one proven machine for each section helps keep production easy to manage and easy to scale.

Below, we walk through each core section and focus on one machine that fits naturally into that role.

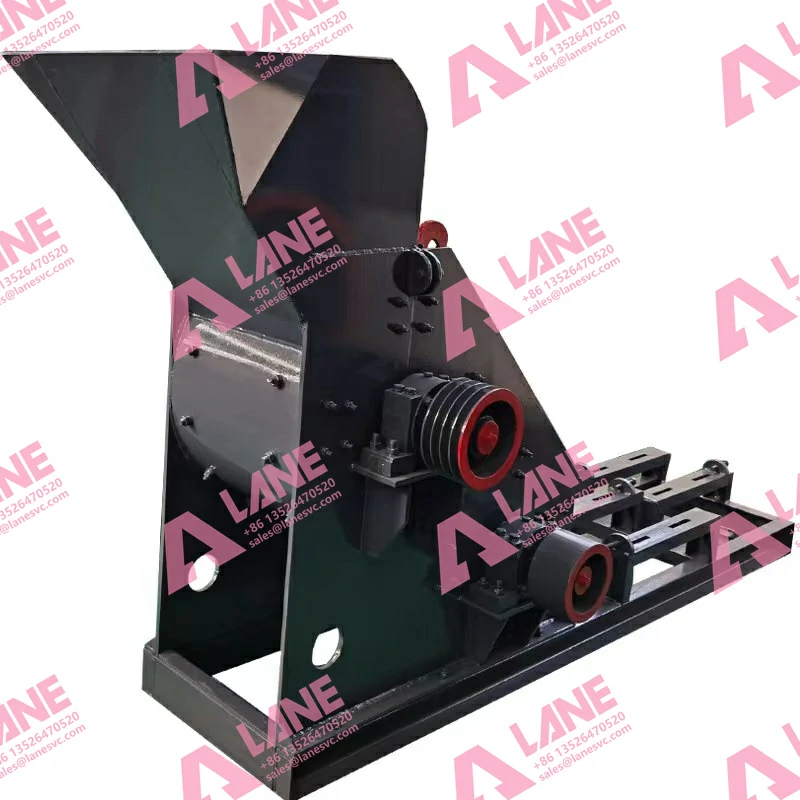

Every successful process begins with consistency. Bentonite often arrives in uneven chunks, which makes uniform production impossible without proper crushing. This is where the hammer crusher proves its value.

A hammer crusher breaks large bentonite blocks into small, manageable particles through high-speed impact. Its internal structure is simple, durable, and easy to maintain, which is especially important in dusty mineral environments. For a bentonite cat litter production line, this machine ensures that all incoming material reaches a uniform size, creating a stable foundation for downstream processing.

By delivering evenly crushed material, the hammer crusher reduces energy waste, prevents blockages, and keeps production running smoothly hour after hour.

Once crushed, bentonite must be conditioned with the right amount of moisture to prepare it for granulation. A horizontal mixer is the ideal choice for this stage.

This mixer uses rotating paddles to blend bentonite powder and water evenly in a short time. The result is a consistent material texture that responds predictably during pellet formation. In a bentonite cat litter production line, even moisture distribution directly affects granule strength and clumping performance.

Because of its enclosed design, the horizontal mixer also minimizes dust and maintains a clean working environment, a small detail that makes a big difference in daily operations.

Granulation remains the central stage of the entire process, and for bentonite cat litter, the disc granulator (also known as a pan granulator) offers an especially efficient and controllable solution. Its open, angled pan design allows conditioned bentonite to roll, gather, and naturally form granules as the disc rotates. This gentle rolling motion encourages uniform bonding, resulting in smooth, rounded particles well-suited for high-quality clumping products.

In a bentonite cat litter production line, the disc granulator stands out for its precise control over particle size. By adjusting parameters such as disc tilt angle, rotational speed, and moisture level, operators can easily fine-tune granule diameter without complex adjustments. This flexibility makes the disc granulator ideal for manufacturers who need stable output while maintaining tight product specifications.

Because of its clear visibility and simple structure, real-time monitoring becomes effortless, allowing operators to quickly correct moisture fluctuations or adjust feed rates. Its energy-efficient design, combined with a relatively small footprint, makes the disc granulator a smart choice for both medium-scale and expanding commercial production.

Durable construction and low wear components help ensure continuous, long-term operation, keeping the granulation process smooth and the overall production line running reliably day after day.

Freshly formed granules still contain excess moisture, which must be removed carefully to ensure durability and shelf stability. A rotary dryer performs this task efficiently and reliably.

As granules move through the rotating cylinder, hot air flows evenly around them, gently reducing moisture without damaging their structure. For a bentonite cat litter production line, this controlled drying process improves granule strength, reduces breakage, and prevents mold during storage.

The rotary dryer’s adaptability to different heat sources also helps manufacturers optimize energy use based on local conditions.

Uniform size is one of the first things customers notice when opening a bag of cat litter. A vibrating screener ensures that only correctly sized granules reach the packaging stage.

This machine separates fine powder and oversized particles through layered screens, sending acceptable granules forward while returning off-size material for reprocessing. In a bentonite cat litter production line, the vibrating screen directly contributes to product appearance, user experience, and brand reputation.

Simple structure and low maintenance requirements make it an efficient and reliable choice for continuous production.

The final stage transforms loose granules into a market-ready product. An automatic packing machine handles weighing, filling, and sealing with high accuracy.

For a bentonite cat litter production line, this machine ensures consistent bag weight, clean sealing, and fast output, helping manufacturers meet commercial demand without sacrificing precision. Automated packaging also reduces labor intensity and supports a professional, retail-ready appearance.

At LANE, we don’t just supply individual machines—we support complete production solutions built around real manufacturing needs. As LANE, we have been specializing in the manufacture of fertilizer machinery in China for more than 20 years. Our experience allows us to design, manufacture, and install complete production lines according to specific customer requirements, including systems similar in structure and logic to a bentonite cat litter production line.

We work with a professional engineering team and offer full-scale services, from equipment installation to comprehensive after-sales support. Whether it involves maintenance, troubleshooting, or future upgrades, we stay connected with our clients to keep production running efficiently. Our quality management follows ISO 9001 and CE international standards, and our expertise spans fertilizer production lines, NPK systems, organic fertilizer machines, and compound fertilizer equipment.

By combining proven technology with practical engineering, we help customers turn concepts into stable, long-term operations.

When each section is matched with the right machine, the entire bentonite cat litter production line becomes easier to operate, easier to maintain, and easier to expand. From crushing and mixing to granulation, drying, screening, and packaging, simplicity and reliability remain the guiding principles.

Choosing equipment that works together—not just individually—creates a production line that delivers consistent quality and dependable performance day after day.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520