Premium organic fertilizers deliver more than just nutrients; it’s an investment in the promise of purity, consistency, and environmental stewardship. With the increased awareness of the value of organic fertilizer, the demand for high-quality organic fertilizer has surged. A certified organic fertilizer production line makes premium fertilizer from organic wastes.

LANE Heavy Industry, a leading manufacturer of agricultural machinery, has developed a modern certified production line that integrates advanced technology, intelligence, and environmental protection. This article takes an in-depth look at the technical details of a modern organic fertilizer production line.

In the organic fertilizer industry, inputs like manure, plant waste, or food scraps contain different nutrients which change from batch to batch. Consistency is the ultimate challenge of organic fertilizer. A certified organic fertilizer production line is not just a collection of equipment. It is a proven system that is designed to eliminate contamination, ensure complete and stabilized decomposition, and produce a uniform product batch after batch. Certification like ISO, OMRI, or local organic regulations provides third-party verification. This certification means that from raw material intake to bag sealing, every aspect is controlled, documented, and repeatable.

A LANE certified organic fertilizer production line is a continuous, integrated line that works like a water stream. LANE Heavy Industry designs each machine to be part of a cohesive ecosystem where every part of the production is calibrated to work with each other to eliminate bottlenecks.

The organic fertilizer journey begins at the raw material sourcing. LANE’s heavy-duty shredders, crushers, and trommel screens are used in this part. Incoming organic raw materials are shredded to a uniform particle size while contaminants like plastics, metals, and stones are removed from the production. This stage ensures the microbial fermentation in the next stage is homogeneous and free from any outside materials.

This is where fermentation occurs. LANE’s compost turners operate within long rows or enclosed tunnels. LANE’s compost turners are customizable. They regularly turn the compost pile, injecting oxygen, regulating temperature, and maintaining optimal moisture.

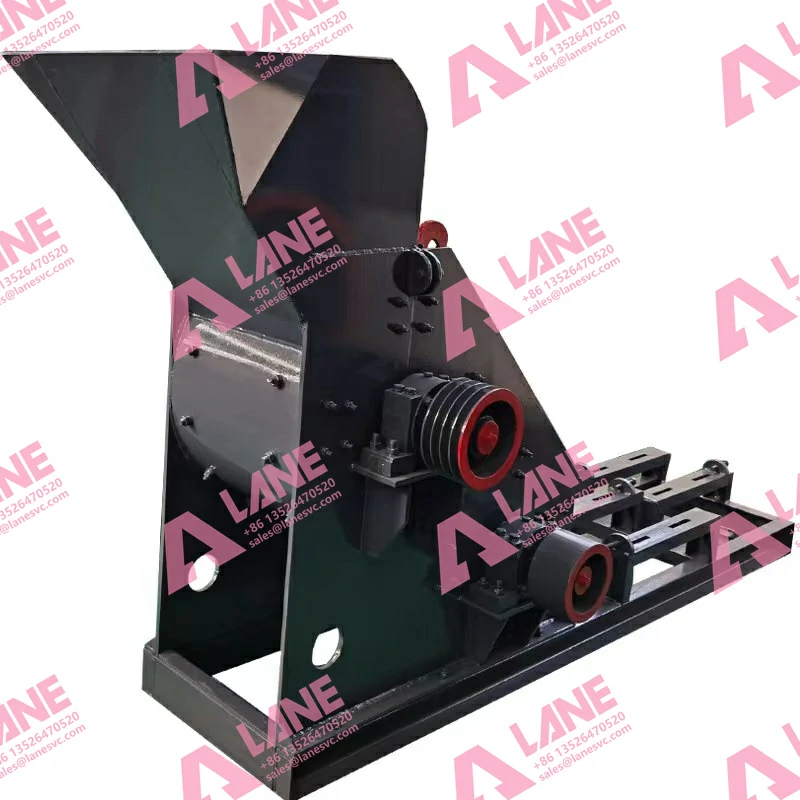

After curing, the matured compost enters the refining phase. LANE’s vertical crusher crushes the compost into fine powder for precise granulation. Oversized fragments are recycled. The powdered compost is then sent to the granulation stage. LANE’s rotary drums or stirring pin granulators create uniform, dust-free granules. After granulation, the granules are sent to the rotary dryer and cooler for moisture reduction and stable granules. The precise control over particle density, size, and hardness in this stage is what gives the final granules a premium price.

The final step in the certified organic fertilizer production line is packaging. LANE integrates fully automated weighing and bagging systems that fill the bags with exact weight precision. After bagging, each bag is labeled with a unique batch code that traces back to the raw material lot and fermentation data, offering transparency to the customers.

LANE Heavy Industry builds production lines depending on the needs of the customer and in compliance with local law. Our certified organic fertilizer production lines are designed with certification protocols in mind:

Hygienic Design: Machines are designed for easy servicing. They have smooth surfaces and can be made with corrosion-resistant materials to prevent cross-contamination.

Integrated Process Control: The production line has a SCADA system implemented. You can monitor and log every parameter across all equipment, generating the reports auditors require. A unified SCADA system monitors and logs every parameter (temperature, moisture, runtime) across all equipment, generating the reports auditors require.

Scalability & Modularity: Production lines can be designed from pilot scale to full industrial output without compromising process control.

LANE Heavy Industry’s modern certified organic fertilizer production line integrates advanced technology, intelligence, and environmental protection. We provide strong technical support for the high-quality development of the organic fertilizer industry. We build infrastructure that builds trust, ensures environmental safety, and delivers performance that farmers can depend on.

Q1: What exactly is being “certified” in a production line?

A: The certification applies to the process and control system. Auditors verify that the entire production line—its equipment, standard operating procedures, and quality control checkpoints—consistently produces a product that meets strict standards for organic integrity, pathogen reduction, heavy metal limits, and stability.

Q2: Can I upgrade my existing facility to a certified production line?

A: Yes, retrofitting is common. The key is integrating equipment, like LANE’s, that offers precise control and data logging, and establishing the required documented procedures (SOPs). It often starts with a core process like controlled fermentation and expands from there.

Q3: Does a certified production line require more labor?

A: Counterintuitively, a well-automated certified production line typically reduces manual labor while increasing technical oversight. Automation handles repetitive tasks (turning, screening, bagging), while personnel focus on monitoring control systems, data analysis, and maintenance—higher-value roles that ensure consistent quality.

Q4: What is the single biggest technical challenge in maintaining certification?

A: Process Consistency. The primary challenge is managing highly variable organic input materials to produce a uniform output. This is solved by engineered preprocessing (like LANE’s shredding and screening) and tightly controlled fermentation, which are the pillars of a robust certified production line.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520