Unlocking Market Access: The Power of a Certified Production Line for Organic Fertilizer

Introduction: The New Benchmark in Organic Fertilizer

Organically produced food is getting popular as increasingly health-conscious people are buying organically produced food. Millennials care more about health and environmental pollution than any previous generation, and research shows that the following generations will also follow in their footsteps. To produce fertilizer for organically produced food, you will need a certified production line.

The organic fertilizer market is expanding at a 12% annual compound growth rate, with international trade accounting for over 25% of the $800 billion market scale. However, from the EU’s strict standards to Southeast Asia’s regulatory frameworks, the market requires more than just quality products; it demands a certified production line that guarantees compliance, traceability, and consistency. This is where LANE Heavy Industry’s certified organic fertilizer production line emerges as a game-changer. It turns regulatory hurdles into competitive advantages.

Beyond Equipment: What is a Truly “Certified Production Line”?

A certified production line is not merely a collection of individual machines that have passed a quality check. It is an integrated system designed and documented to produce organic fertilizer that meets the exacting protocols of recognized certification bodies (such as the USDA NOP, EU Eco regulations, or OFC).

It encompasses the following protocols:

- Process Integrity: The organic fertilizer production line must ensure complete traceability from raw material (e.g., manure, plant waste) to finished granules. It must prevent contamination from prohibited materials and maintain the organic “chain of custody.”

- Equipment Suitability: Machinery must be made with industrial-grade, non-reactive materials. The machinery must be easy to clean and must have cross-contamination prevention methods implemented. The factory must also have dust control.

- Documentation & Control: The production line must have systems that facilitate easy data logging of process parameters to provide auditable proof of compliant operation.

The Market Access Imperative: Why Certification is Your Key

A certified production line acts as your passport to the most lucrative fertilizer markets:

- Selling to Certified Organic Farms: Organic farms are legally required to use inputs from certified sources. Your certification is their assurance, making you an approved supplier.

- Entering Export Markets: International trade, especially with regions like the European Union or North America, mandates compliance with their organic standards. A certified line is a mandatory prerequisite in these countries.

- Winning Government & Large-Scale Contracts: Tenders for municipal compost projects or large agricultural cooperatives require certification as a bid qualification. It ensures there is no risk of contamination in the supply chain.

- Commanding a Price Premium: Certified fertilizer is a documented, high-assurance product. Buyers pay more for this reliability. It directly boosts profit margins.

LANE Heavy Industry’s Blueprint for a Certified Line

At LANE Heavy Industry, we engineer certified production lines from the ground up. We integrate compliance into every stage:

- Pre-Processing & Fermentation: Our automated feed mixers and fermentation tanks ensure uniform and controlled aerobic decomposition. This creates a stable, pathogen-free base material. It is the first critical step for certification.

- Precision Crushing & Screening: After fermenting and curing, the fermented materials go through a crushing stage to be refined into a consistent particle size. It’s crucial for granulation efficiency and final product quality.

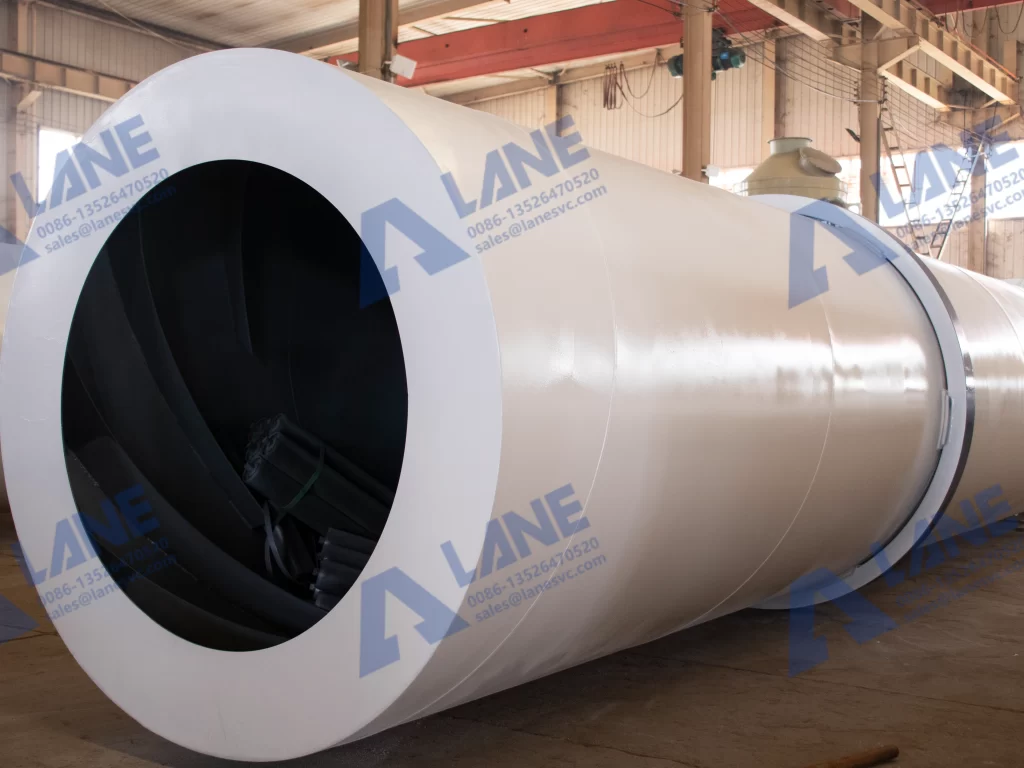

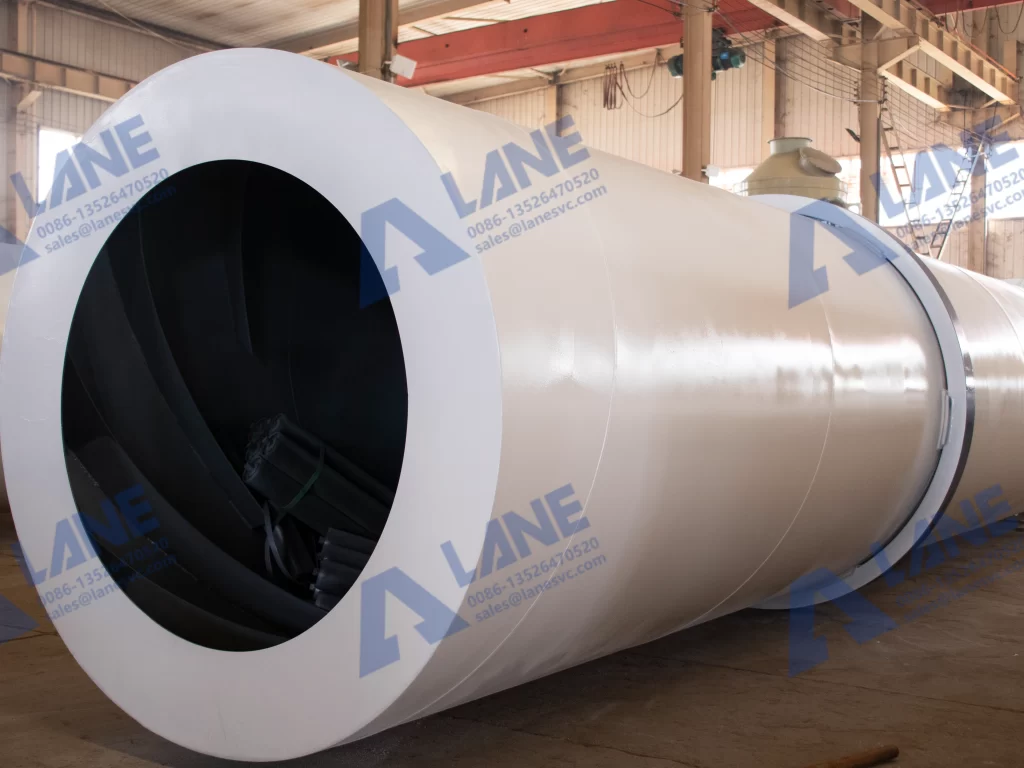

- Granulation & Shaping (The Core):Our organic fertilizer granulators, such as the Stirring Pin Granulator or Rotary Drum Granulator, are designed with easy-clean surfaces and precise moisture/temperature controls to produce uniform, stable pellets.

- Drying, Cooling & Coating: The granules are wet when they come out of the granulator. They are sent to the rotary dryer and cooler, which use indirect heat to preserve microbial life and nutrients. After that, they are sent to the screening machine. It separates on-size granules from fines and oversized granules and sends them back to the crusher to be recycled. On-size granules are sent to the polishing drum. A polishing drum can apply certified organic coatings for dust reduction and enhanced nutrient delivery.

- Automated Packaging & Data Logging: This is the final step of the production line. An automatic packaging line weighs and packs the final product while the computer system logs the details of every batch’s process data. It creates an irrefutable audit trail.

Tangible Benefits: From Operational Consistency to Brand Premium

Buying a certified production line from LANE yields returns which extend far beyond a certificate on the wall:

- Unwavering Product Consistency: Automation and controlled processes eliminate batch-to-batch variation, which builds unwavering customer loyalty.

- Operational Efficiency & Reduced Waste: LANE’s optimized, integrated machinery maximizes yield and minimizes energy and raw material waste.

- Future-Proofing Your Business: Regulations for the fertilizer industry will keep tightening. As regulations tighten, your certified infrastructure ensures ongoing compliance. It protects your market access for years to come.

The Investment Perspective: Cost vs. Strategic Value

A certified production line is not a capital expense; it is a strategic investment with a clear ROI:

- Cost of Entry vs. Cost of Exclusion: The initial investment in the production line is offset by accessing higher-margin markets. The cost of being excluded from these markets is far greater.

- Reduced Compliance Risk: Avoid costly fines, batch rejections, and lost contracts due to non-compliance.

- Long-Term Asset Value: A documented, compliant production facility is a more valuable and saleable asset.

FAQ: Your Questions on Certified Production Lines, Answered

Q1: Does buying a certified line automatically make my fertilizer certified?

A1: No. The line provides the compliant platform. You must still operate it according to protocol and undergo an audit by a certification body for your product and process to receive official certification.

Q2: Can I upgrade my existing production line to become certified?

A2: Potentially, yes. LANE Heavy Industry offers audit and retrofit services. We assess your current setup and recommend specific machinery upgrades (like replacing carbon steel components with stainless steel) and process controls to achieve certification standards.

Q3: How does LANE ensure its lines meet different international standards?

A3: Our engineering team designs to the most stringent global benchmarks (e.g., EU and NOP). We provide comprehensive documentation packs and can advise on process parameters specific to your target market’s requirements.

Q4: Is the operation of a certified line more complex?

A4: Not more complex, but more disciplined. The line itself is often more automated. The key difference is the rigorous documentation of process data, which LANE’s systems are built to facilitate seamlessly.

Conclusion: Building the Future on a Certified Foundation

In the global organic fertilizer market, a certified production line is the key to unlocking global opportunities. It creates trust among buyers. LANE Heavy Industry’s certified line combines regulatory compliance, operational efficiency, and sustainability, empowering businesses to navigate complex market requirements and turn green agriculture into a profitable venture.