In the age of sustainability, circular agriculture with on-site composting has emerged as a transformative solution for farmers seeking to close the loop in their farming operations.This method not only helps reduce waste but also improves soil health, reduces the carbon footprint of agriculture, and brings about more sustainable agricultural practices.

As people increasingly attach importance to environmental responsibility and resource efficiency, circular agriculture is becoming a key element of modern agriculture. It is an integrated approach that combines waste management, nutrient cycling, and soil improvement, enabling farms to become more self-sufficient while contributing to a healthier planet.

What Is Circular Agriculture with On-Site Composting?

Circular agriculture refers to an agricultural system that mimics natural processes, where nutrients are continuously recycled within the ecosystem. In traditional agriculture, waste is often discarded or treated as by-products, thereby causing harm to the environment. However, circular agriculture with on-site composting seeks to reverse this trend by using waste (especially organic waste like crop residues, livestock manure, and food scraps) as a resource for creating valuable compost that can be reused to nourish the soil.

By adopting the circular agriculture with on-site composting method, farms can recycle organic waste, convert it into nutrient-rich compost, and use it to enhance soil fertility. This approach reduces reliance on synthetic fertilizers, minimizes waste, and contributes to the circular economy of agriculture.

Benefits of Circular Agriculture with On-Site Composting

Waste Reduction and Nutrient Recycling

One of the main advantages of circular agriculture with on-site composting is that it minimizes the need for external waste disposal. Farms do not have to send organic waste to landfills or incinerators; instead, they can recycle it on-site and turn it into valuable compost, converting waste into resources. This reduces the environmental impact of waste disposal and helps to retain valuable nutrients within the agricultural system.

Improved Soil Health

Organic material composting not only recycles nutrients but also helps improve soil structure and microbial activity. On-site composting can produce compost rich in humus, which enhances soil aeration, water retention, and nutrient content. Over time, this will make the soil healthier and more resilient, thereby increasing crop yields and reducing the need for chemical fertilizers.

Lower Input Costs

Through circular agriculture with on-site composting, farmers can reduce their reliance on expensive synthetic fertilizers. Compost made from organic waste can be directly applied to the fields, thereby lowering the cost of purchasing and transporting fertilizers. Moreover, since the composting process takes place locally, there is no need to bear the transportation costs of external fertilizers.

Environmental Sustainability

Circular agriculture is fundamentally environmentally friendly because it can promote biodiversity, reduce waste, and minimize carbon emissions. By creating a nutrient loop through on-site composting, the farm helps protect the soil, reduces greenhouse gas emissions, and minimizes the negative impacts of waste disposal.

Energy and Resource Efficiency

On-site composting helps enhance resource efficiency by utilizing locally available organic waste. This reduces the demand for energy-intensive fertilizer production and transportation, making agricultural practices more energy-efficient and resource-conscious.

The Process of Circular Agriculture with On-Site Composting

Circular agriculture with on-site composting is a relatively simple but highly efficient process. It involves collecting organic waste, managing the composting conditions, and applying the finished product to the soil. Here is an overview of the typical process:

(1) Collection of Organic Waste

Organic waste materials such as crop residues, animal manure, food scraps, and garden waste are collected from the farm. These materials are rich in nutrients and can be turned into compost through controlled decomposition.

LANE Equipment:

Waste collection bins and belt conveyors – Efficient systems for gathering and transporting organic waste to composting areas.

(2) Preprocessing and Size Reduction

The collected waste may need to be shredded or ground to smaller particles to enhance the breakdown process. The smaller the particle size, the faster the decomposition, as it increases the surface area for microbial activity.

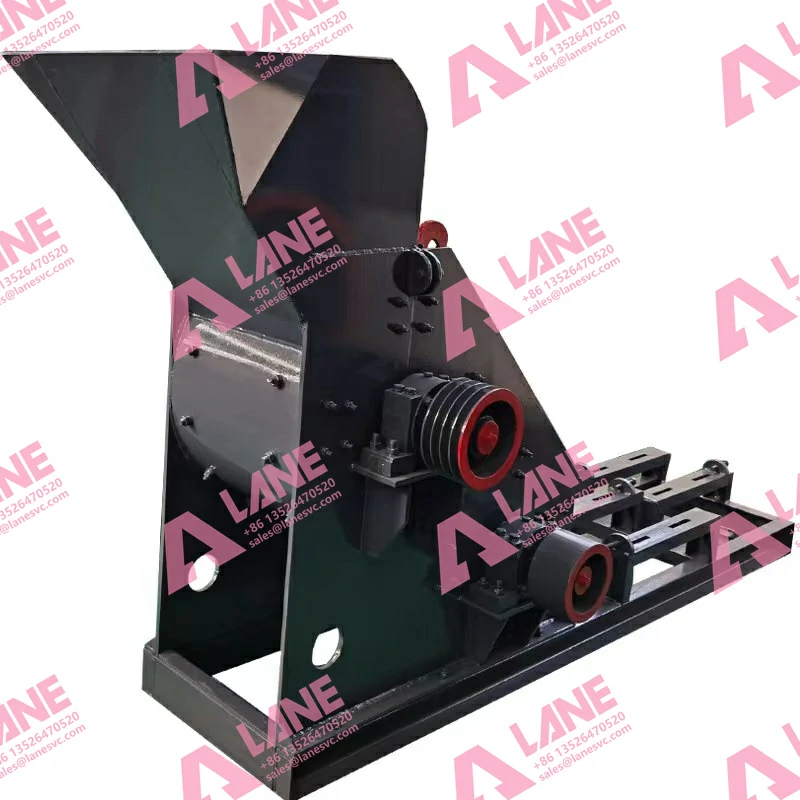

LANE Equipment:

Shredder or hammer crusher – This equipment reduces waste into smaller, more manageable pieces, speeding up the composting process.

(3) Aerobic Decomposition

The organic materials are mixed and turned to introduce oxygen into the pile. This aerobic decomposition process is facilitated by the use of compost turners, which break up the pile, ensuring that oxygen reaches all parts of the material. Proper aeration prevents anaerobic decomposition, which can lead to the production of harmful gases like methane.

LANE Equipment:

Crawler type compost turner or wheeled compost turner– LANE’s heavy-duty crawler compost turner provides superior mixing and aeration for large-scale composting operations.

(4) Monitoring and Maintenance

During the composting process, regular monitoring of temperature, moisture, and pH levels is essential to ensure optimal conditions for microbial activity. The compost pile needs to be turned regularly to maintain consistent temperature and oxygen levels, which speed up the decomposition process.

LANE Equipment:

Temperature and moisture sensors – Real-time monitoring equipment to ensure that composting conditions are ideal for nutrient breakdown.

(5) Final Product: Nutrient-Rich Compost

After several weeks to months, depending on the material, the compost is ready for use. The final product is a rich, dark, crumbly material full of essential nutrients that can be applied back to the soil to improve its health and fertility.

LANE Equipment:

Storage and Packaging Machines – For easy storage of the final compost product, ready for distribution or application.

Real-World Application: Circular Agriculture with On-Site Composting in Action

To fully understand the impact of circular agriculture with on-site composting, it’s essential to look at how this approach has transformed real-world farms and businesses. Let’s explore several cases to understand how on-site composting systems have completely revolutionized waste management, reduced costs, and promoted more sustainable agricultural practices.

Case 1: A Large Dairy Farm in New Zealand

A large dairy farm in New Zealand faced significant challenges in managing the large amounts of manure produced daily. Traditionally, manure was either left to accumulate in piles or sent off-site for disposal, causing environmental concerns and increasing waste management costs.

By adopting circular agriculture with on-site composting, the farm implemented a LANE composting system, including a crawler-type compost turner and composting bins. This change allowed the farm to process its manure into valuable compost on-site, reducing the need for external disposal services.

The Results:

Waste Reduction: The farm was able to cut waste disposal costs by 50%, thanks to on-site composting.

Nutrient-Rich Compost: The compost produced from manure was used to fertilize crops on the farm, reducing the need for synthetic fertilizers and improving soil health.

Environmental Benefits: The farm saw a decrease in odors and greenhouse gas emissions, aligning with local environmental regulations and sustainability goals.

This example demonstrates the power of on-site composting in turning waste into a resource, reducing costs, and improving the farm’s overall sustainability.

Case 2: A Vegetable Farm in India

A vegetable farm in India, located in a region with high levels of agricultural waste, decided to implement circular agriculture with on-site composting to handle the significant volume of crop residues and plant-based organic waste. The farm’s goal was to reduce its dependency on chemical fertilizers while simultaneously addressing the challenge of organic waste disposal.

With LANE’s composting system, the farm was able to process leftover vegetable matter, plant stems, and leaves into high-quality compost. The process used LANE’s crawler-type compost turner and a set of rotary drum dryers to ensure the compost was evenly aerated and dried.

The Results:

Soil Improvement: The use of compost enriched the soil, leading to a 15% increase in vegetable yield over the next growing season.

Reduced Fertilizer Costs: The farm saved 25% on fertilizer costs, thanks to the nutrient-rich compost they produced on-site.

Waste Reduction: The farm completely eliminated the need for external waste disposal services, ensuring that all organic waste was recycled and reused.

By adopting on-site composting, this farm not only tackled its waste problem but also improved crop yields, cut costs, and created a more sustainable, circular farming system.

These case studies demonstrate how circular agriculture with on-site composting has not only helped individual farms but entire communities adopt sustainable practices that reduce waste, enhance soil fertility, and contribute to long-term agricultural resilience. hrough LANE’s comprehensive solution (including advanced composting technology), farmers and municipal authorities are benefiting from this closed-loop system, showcasing the potential of composting in promoting the sustainable development of modern agriculture.

LANE’s Customizable On-Site Composting Solutions

At LANE, we specialize in providing customized solutions for circular agriculture with on-site composting. In LANE, we focus on providing customized circular agriculture solutions and offer on-site composting services. Our system is designed to maximize efficiency, reduce waste, and produce high-quality compost for improving soil health and increasing crop yields.

1.Customized systems for each farm

We understand that each farm has its unique requirements. Our on-site composting system is highly customizable, and you can tailor the equipment according to your specific organic waste management needs. Whether you are composting manure, crop residues, or kitchen waste, we can design a suitable system for you.

2.Energy-efficient and durable equipment

Our composting equipment, such as crawler type compost turners, is built to last and operate efficiently, reducing energy consumption and labor costs.

3.Expert support and training

LANE not only provides top-notch equipment but also offers expert support, including system installation, training, and maintenance. We ensure that your composting system operates at maximum efficiency, maximizes productivity, and minimizes downtime.

For modern farms that aim to enhance sustainability, reduce waste and create healthier soil, adopting circular agriculture with on-site composting is a crucial solution. By converting organic waste into high-quality compost, farms can reduce their reliance on synthetic fertilizers, enhance soil fertility, and increase crop yields. With LANE’s customized solutions, you can implement an efficient and sustainable composting process based on your farm’s needs, thereby helping you reduce costs, enhance environmental sustainability, and achieve long-term agricultural success.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520