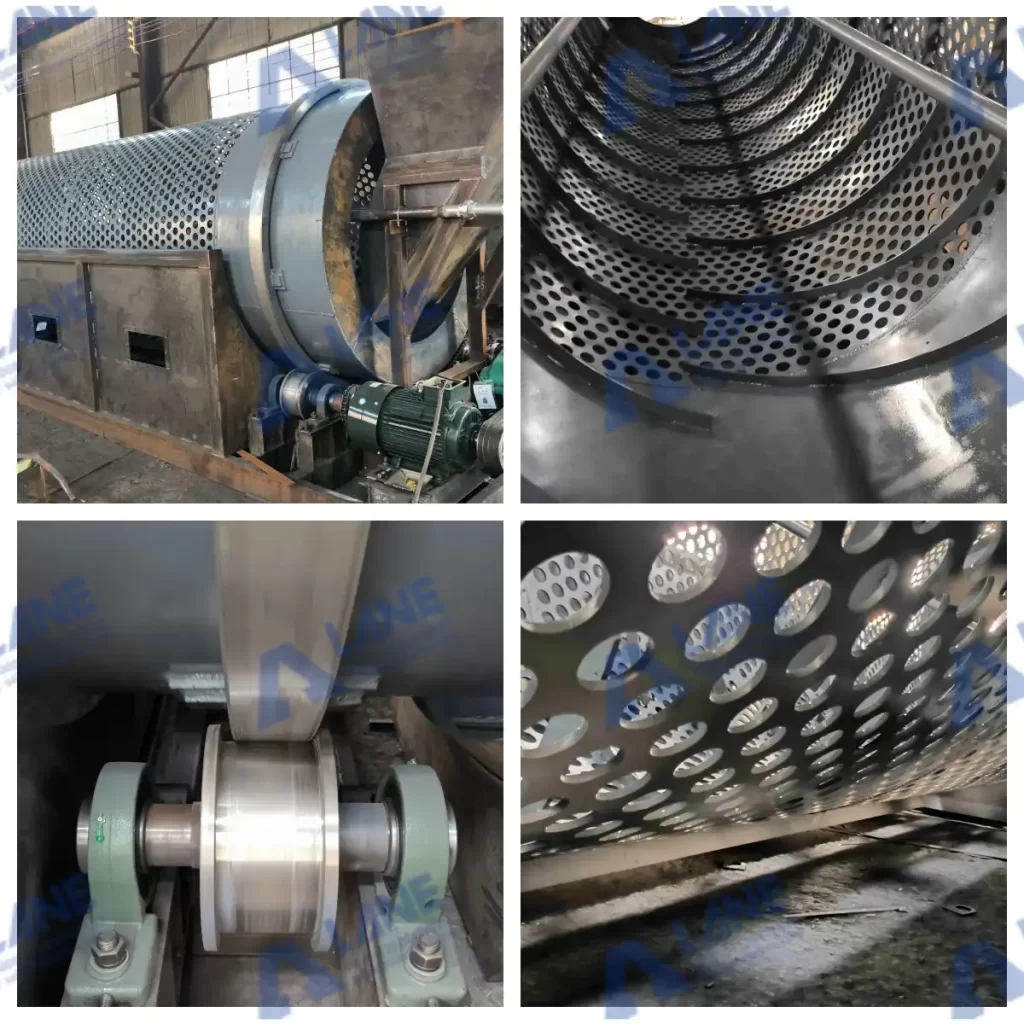

The drum cleaning machine is a robust, rotary drum washer engineered to thoroughly clean fertilizer drums used in granulation, composting, or mixing processes. Its rotating drum design, paired with high-pressure spraying and optional brush systems, ensures efficient removal of dried fertilizer residues, muck, and stubborn build-up from inside and outside surfaces. This keeps your equipment sanitary, reduces contamination risks, and ensures product purity.

Drum cleaning machine |

||

|---|---|---|

| Speciation | Range/Value | Notes |

| Drum Diameter | 800mm-2000mm | Custom sizes available |

| Drum Length | 2000mm-5000mm | Adjustable to production needs |

| Material | Carbon steel/Stainless steel | Corrosion and wear-resistant |

| Cleaning Mechanism | High-pressure nozzles | Ensures thorough residue removal |

The drum cleaning machine operates on a rotary washing mechanism. Fertilizer drums are fed into the rotating cylinder, where high-pressure nozzles spray water or cleaning solution across the entire surface. The constant rotation ensures that both the inner and outer walls of the drum are evenly exposed to the cleaning jets.

For more demanding applications, optional internal brushes provide mechanical scrubbing to remove stubborn residues such as caked fertilizer or organic deposits. The wastewater is collected at the base, filtered, and optionally recirculated to reduce water consumption.

By combining hydraulic flushing, rotary motion, and mechanical brushing, the drum cleaning machine achieves fast, thorough cleaning with minimal manual intervention, keeping production drums ready for reuse and maintaining high hygiene standards in fertilizer production.

The drum cleaning machine is designed to meet the strict requirements of modern fertilizer production, ensuring drums remain clean, safe, and efficient for continuous use. By reducing residue build-up and contamination risks, it helps manufacturers maintain product quality while lowering maintenance costs.

Thorough Cleaning

Multidirectional high-pressure jets and optional internal brushes ensure complete residue removal—including caked fertilizer—from both interior and exterior drum surfaces.

Hygiene & Contamination Control

Maintaining clean drums prevents cross-contamination and upholds product integrity—critical in organic fertilizer production.

Efficient Operation

Capable of cleaning dozens to hundreds of drums per hour, enabling continuous production flow with minimal downtime.

Durable Construction

Built with robust materials, wear-resistant linings, and sealed housings to withstand abrasive residue and extend service lifespan.

Water Conservation

Optional recirculation systems with filtering minimize water use and promote sustainable operation.

Adaptable Design

Supports multiple drum sizes, power voltages, and cleaning modules, helping it fit seamlessly across various production setups.

In summary, the drum cleaning machine ensures cleaner operations, reduces downtime, and supports long-term efficiency in fertilizer production lines.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

World-class and Energy-saving Operation, Factory Price & Fast Delivery.