Durian is one of Southeast Asia’s most iconic fruits—and one of the messiest. Every ton of durian harvested generates more than half a ton of shells and fibrous husk material. For years, these shells were treated as a disposal problem: smelly, bulky, difficult to burn, and slow to decompose naturally. But as the global organic fertilizer market grows, many farms, waste-processing centers, and agricultural companies are discovering a surprising new opportunity: durian shell fertilizer production.

Durian shells are rich in lignin, cellulose, and trace minerals, making them a promising raw material for producing organic fertilizer—especially when combined with fermentation and modern fertilizer machinery. By using a biomass crusher, fermentation equipment, a pellet granulator, dryer, cooler, and automatic packaging machine, producers can turn local waste into export-ready organic fertilizer pellets.

This article explores exactly how durian shell fertilizer production works, why it is profitable, and how specialized equipment ensures stability, efficiency, and high product quality.

Why Are Durian Shells Ideal for Organic Fertilizer Production?

At first glance, durian shells seem far from suitable for agriculture. They are hard, fibrous, and slow to break down. Yet these “weaknesses” are exactly what make them valuable in durian shell fertilizer production.

Durian shells contain:

Because of these advantages, companies across Malaysia, Thailand, Indonesia, and the Philippines have begun turning durian waste into stable, clean, nutrient-rich organic fertilizer pellets.

As markets shift toward environmentally friendly fertilizers, durian shell fertilizer production becomes not only feasible but financially compelling.

What Makes Durian Shell Fertilizer Production Different From Other Organic Materials?

Compared to chicken manure, cow manure, or crop straw, durian shells require more intensive pre-processing. Their thickness and hardness demand mechanical intervention. This means the production line must start with a powerful biomass crusher before fermentation can occur.

However, once properly crushed, the shells ferment beautifully. They absorb moisture evenly, retain heat during microbial activity, and break down into a dark, nutrient-rich compost suitable for pelletizing.

This is why durian shell fertilizer production relies heavily on specialized machines tailored to tough biomass materials.

Step-By-Step: How Durian Shells Become Organic Fertilizer Pellets

Below is the complete workflow used in modern durian shell fertilizer production, from raw material to finished pellets.

Durian shells are extremely hard, making a biomass crusher essential. Without crushing, fermentation would be nearly impossible.

A typical biomass or hammer crusher used in durian shell fertilizer production features:

High-speed rotating blades

Heavy-duty steel structure

Adjustable particle size

Ability to handle shell debris, fibers, and husk fragments

Crushing reduces the shell pieces to 3–5 mm particles, increasing surface area and allowing microorganisms to thrive during fermentation.

Crushed shells must be mixed with nitrogen-rich additives such as:

This ensures proper fermentation. The ideal moisture for durian shell fertilizer production is 55–65%, and the carbon–nitrogen ratio should be balanced at 25–30:1.

A horizontal or vertical mixing machine ensures uniform blending before fermentation begins.

Fermentation is the heart of durian shell fertilizer production. Because shells retain heat well, composting is efficient when using the right equipment.

Producers can choose from:

These enclosed tanks allow:

Aerobic fermentation

Temperature control

Odor reduction

Rapid biological decomposition

Durian shell material typically ferments for 7–15 days, depending on the microbial strain and moisture.

Ideal for large-scale operations with long rows of compost.

These machines help turn thick layers of high-carbon material like durian shells.

During fermentation, temperature rises to 55–70°C, killing pathogens and speeding decomposition.

The result: a dark, soft, soil-like material suitable for granulation.

Some producers choose a secondary crushing step to further refine particle size, especially if the initial shell pieces were large.

A screening machine may also be used to remove oversized pieces before granulation.

After fermentation, the material is ready for granulation. This is one of the most critical parts of durian shell fertilizer production because pellets:

Are easier to store

Have higher commercial value

Are suitable for export

Offer controlled nutrient release

Machines used include:

Round, uniform pellets

Adjustable diameter

Ideal for medium-scale factories

High capacity

Strong pellet hardness

Suitable for large industrial operations

High-density cylindrical pellets

Excellent for biomass-based fertilizers

During granulation, moisture rises slightly to help pellet formation, typically reaching 30–35%.

Because fresh pellets contain too much moisture, a rotary drum dryer is used.

Drying reduces moisture to 10–12%, preventing mold and extending shelf life.

The dryer works with:

High-temperature airflow

Rolling motion

Continuous heating

For durian shell fertilizer production, drying ensures the pellets remain durable and crack-resistant.

After drying, pellets remain warm and fragile. A counterflow cooler lowers the temperature to avoid breakage during packaging.

Cooling benefits include:

Improved pellet hardness

Reduced moisture

Prevention of thermal expansion

Cooling is essential for maintaining the premium appearance of pellets in durian shell fertilizer production.

To achieve commercial-grade pellets:

A screening machine removes powder or irregular pellets

A polishing machine produces glossy, attractive surfaces

This step increases market value, especially for export markets in Japan, Korea, and Europe.

Finished pellets are packed using:

Automatic weighing machines

Sealing machines

Bag stitching machines

Standard bags include 25 kg, 40 kg, and 50 kg packaging.

Strong, dry, cooled pellets ensure that durian shell fertilizer production results in a stable, premium product.

What Makes Durian Shell Fertilizer Valuable in the Market?

Pellets produced through durian shell fertilizer production have major advantages:

These benefits make durian shell pellets attractive for:

In regions producing large amounts of durian, fertilizer factories have a continuous supply of raw material at minimal cost.

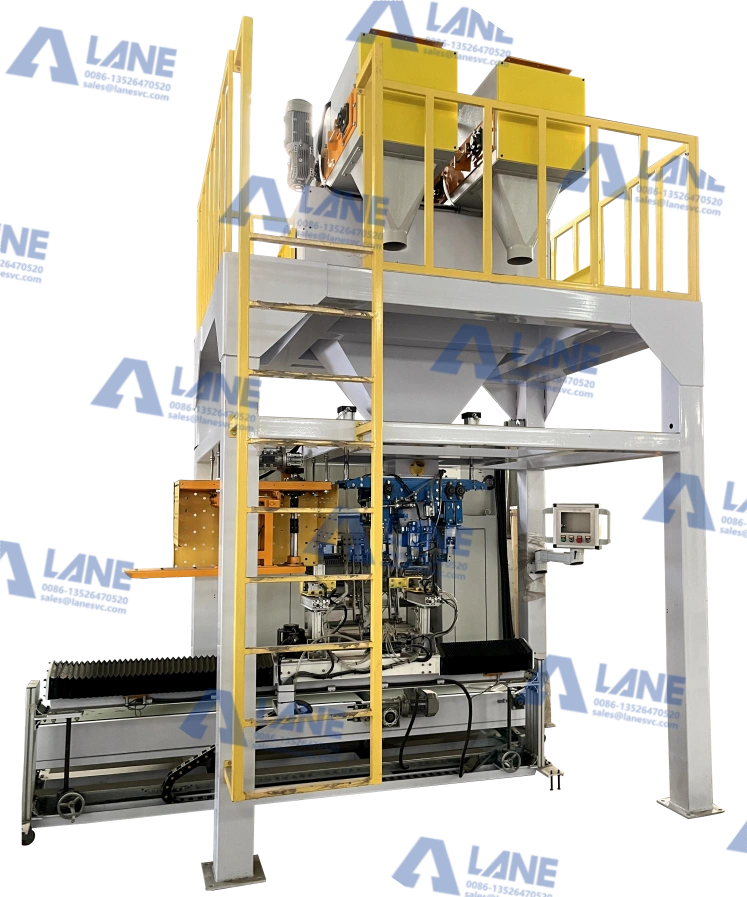

LANE: The Trusted Supplier Behind Durian Shell Fertilizer Production Lines

When establishing or expanding a durian shell fertilizer production facility, choosing reliable equipment manufacturers is essential. This is where LANE stands out.

LANE has:

20+ years of experience manufacturing fertilizer machinery in China

A professional engineering team capable of designing customized complete production lines

Expertise in installation, commissioning, maintenance, troubleshooting, and upgrading

Compliance with ISO 9001 and CE international quality standards

Strong production lines for organic fertilizer, NPK fertilizer, and compound fertilizer machinery

The ability to provide direct factory pricing for global customers

LANE’s comprehensive service—from project design to after-sales support—makes it a top choice for companies engaged in durian shell fertilizer production or any biomass-based fertilizer industry.

Why Is the Market for Durian Shell Fertilizer Growing So Fast?

Several major factors drive this trend:

Organic farming is booming worldwide

Waste-to-resource projects gain government support

Durian production increases each year

Import demand for organic pellets expands in major markets

Fertilizer prices fluctuate, encouraging local production

With these trends, durian shell fertilizer production is becoming a high-margin business for both small farms and large industrial facilities.

Conclusion: Turning Waste Into Opportunity

Durian shells, once seen as a disposal burden, now represent one of Southeast Asia’s most overlooked agricultural resources. With the right equipment—crushers, fermentation tanks, granulators, dryers, coolers, and packaging machines—any producer can transform discarded shells into valuable organic fertilizer pellets.

As global demand grows, durian shell fertilizer production continues to attract investors, farmers, and agricultural companies seeking sustainable, profitable solutions. With strong partners like LANE providing reliable machinery and full technical support, turning durian waste into high-quality fertilizer becomes not only possible but deeply rewarding.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520