In recent years, agriculture has been under growing pressure to become cleaner and more responsible. Farmers, governments, and consumers are all paying closer attention to how food is produced and how soil is treated. In this shift, eco-friendly fertilizer production equipment plays a quiet but powerful role. These machines help turn organic materials into useful fertilizers while keeping emissions, waste, and energy use under control.

Organic fertilizer production is not just about recycling waste. It is about building a system where natural resources are respected and reused. Production equipment sits right at the center of this system. When designed well, it supports both productivity and environmental care, making it easier for producers to meet modern standards without adding complexity to daily operations.

Organic fertilizers improve soil structure, increase water retention, and support healthy microbial life. Unlike chemical fertilizers, they release nutrients slowly and reduce the risk of soil degradation. However, the environmental value of organic fertilizer depends heavily on how it is produced.

Traditional production methods can waste raw materials, consume too much energy, or release unpleasant odors and dust. This is where eco-friendly fertilizer production equipment makes a real difference. Modern machines are designed to manage temperature, moisture, and airflow more precisely, which helps protect the environment while producing a consistent, high-quality product.

Today’s fertilizer equipment is built with efficiency and control in mind. Crushing, mixing, granulating, drying, and cooling are no longer rough, energy-heavy steps. Instead, they are carefully connected processes that work together smoothly.

Using eco-friendly fertilizer production equipment , producers can reduce material loss and improve output quality. For example, sealed systems help limit dust and odor, while optimized dryers lower fuel use. This not only protects the surrounding environment but also creates a safer and cleaner workplace for operators.

Organic fertilizer production often starts with materials like animal manure, crop residues, or food waste. Without proper handling, these materials can become pollutants. Modern production equipment turns this challenge into an opportunity.

By using eco-friendly fertilizer production equipment , waste is transformed into value. Composting systems stabilize raw materials, while screening and granulation ensure uniform fertilizer size. This reduces the need for reprocessing and cuts down on unnecessary disposal, supporting a circular economy approach that many regions now encourage.

Sustainability is not only about the environment; it is also about long-term economic health. Energy-efficient machines consume less power and fuel, helping producers control operating costs over time.

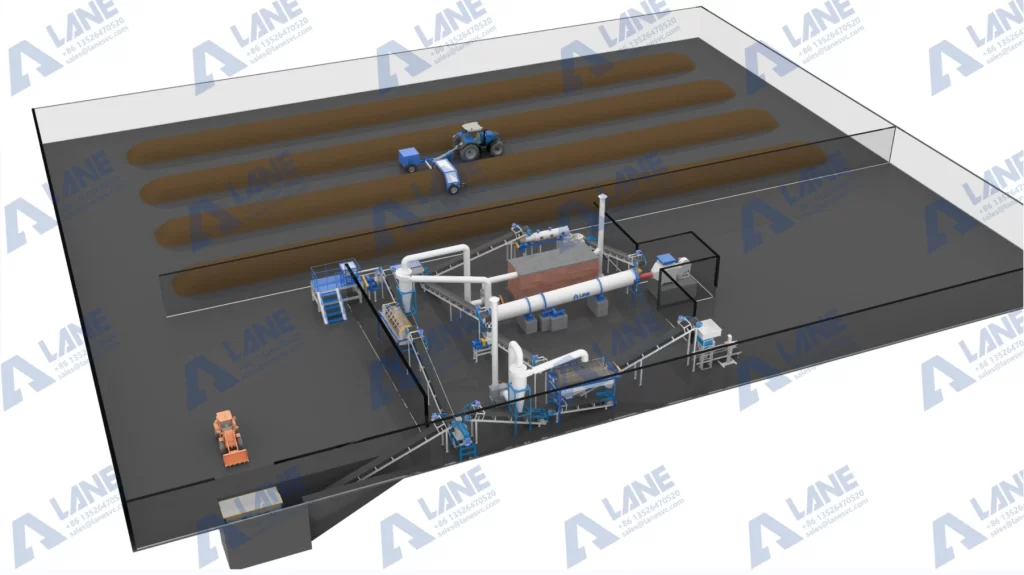

Well-designed eco-friendly fertilizer production equipment often includes heat recovery systems, efficient motors, and automated controls. These features may seem small on their own, but together they create noticeable savings and more predictable production performance, which is especially important for large-scale fertilizer plants.

One important advantage of modern fertilizer machinery is flexibility. Small farms, regional producers, and industrial operations all have different needs. Equipment must adapt to these differences without sacrificing environmental performance.

With eco-friendly fertilizer production equipment , production lines can be scaled up or down depending on demand. Modular designs allow producers to start with basic systems and expand later. This flexibility lowers entry barriers and helps more businesses move toward sustainable fertilizer production.

At LANE, we have spent more than 20 years focused on fertilizer machinery manufacturing in China. During this time, we have seen how environmental awareness has reshaped the industry. We design and build eco-friendly fertilizer production equipment that balances efficiency, durability, and environmental responsibility.

Our professional engineering team works closely with clients to understand their raw materials, capacity goals, and site conditions. We believe that no two projects are the same, so we offer customized equipment and complete production line solutions rather than one-size-fits-all machines.

We do more than supply machines. We support our customers through the entire process, from early planning to installation and daily operation. Our team handles equipment layout, on-site installation, and commissioning to ensure the production line runs smoothly from day one.

With our eco-friendly fertilizer production equipment , we also provide long-term after-sales service. This includes maintenance guidance, troubleshooting, and system upgrades. Our goal is to help producers keep their lines running efficiently and stably for years, not just during the first production season.

Reliability is essential in fertilizer production. Equipment failures can interrupt production and increase waste. That is why we place strong emphasis on quality control and international standards.

Our machines meet ISO9001 quality management requirements and CE certification standards. This means our eco-friendly fertilizer production equipment is designed and manufactured with safety, consistency, and global market needs in mind. These standards help our customers feel confident when investing in long-term production assets.

Organic fertilizer production involves many steps, and each step requires the right equipment. We specialize in machinery for organic fertilizer, compound fertilizer, and liquid fertilizer production. This complete product range allows us to design fully integrated lines that work efficiently as a whole.

By combining our experience with eco-friendly fertilizer production equipment , we help producers create cleaner processes that align with modern environmental goals. Whether the focus is reducing emissions, saving energy, or improving product quality, the right equipment makes those goals achievable.

Sustainable fertilizer production is no longer a niche idea. It is quickly becoming the standard across global agriculture. Equipment choices made today will shape environmental impact for decades to come.

As technology continues to improve, eco-friendly designs will become even more accessible and cost-effective. Producers who invest early in cleaner systems are better positioned to meet regulations, satisfy market expectations, and protect natural resources.

Organic fertilizer production and environmental protection are closely connected. The machines used in production influence not only efficiency but also the health of surrounding ecosystems. By choosing modern, well-designed equipment, producers can support sustainable agriculture without sacrificing performance.

At LANE, we are proud to contribute to this transition by offering reliable, customizable, and environmentally responsible fertilizer production solutions. We believe that practical technology, backed by experience and service, is the key to building a greener fertilizer industry for the future.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520