An Eco-Friendly Organic Fertilizer Production Line uses agricultural and food waste as raw materials and transforms them into a resource for improving soil fertility. This production line creates a profitable business which helps manage organic waste and gain economic value. By investing in such system, you are not only buying machinery you are also investing in circular economy. This model closes the loop on waste, rehabilitates land, and generates value from previously discarded materials.

This article explores how a modern Eco-Friendly Organic Fertilizer Production Line creates consistent premium liquid fertilizer while promoting sustainable agriculture.

Table of Contents

Decades of over-reliance on chemical fertilizers have depleted soil organic matter, destroyed microbial ecosystems, and reduced soil fertility, leading to lower crop yields and quality over time. On the other hand, agricultural and food processing industries generate millions of tons of organic waste annually. From livestock manure and crop residues to shellfish shells, cocoa pods, and soybean dregs, waste ends up in landfills or is burned, contributing to pollution and greenhouse gas emissions.

A customized, engineered Eco-Friendly Organic Fertilizer Production Line turns this waste into an opportunity. It provides a systematic, controlled method to recycle these raw materials into an economically valuable product. That’s where LANE Heavy Industry’s Eco-Friendly Organic Fertilizer Production Line comes into play. Our innovative Eco-Friendly Organic Fertilizer Production Line turns organic waste into high-quality organic fertilizer and creates a circular economy that benefits both the environment and agricultural businesses.

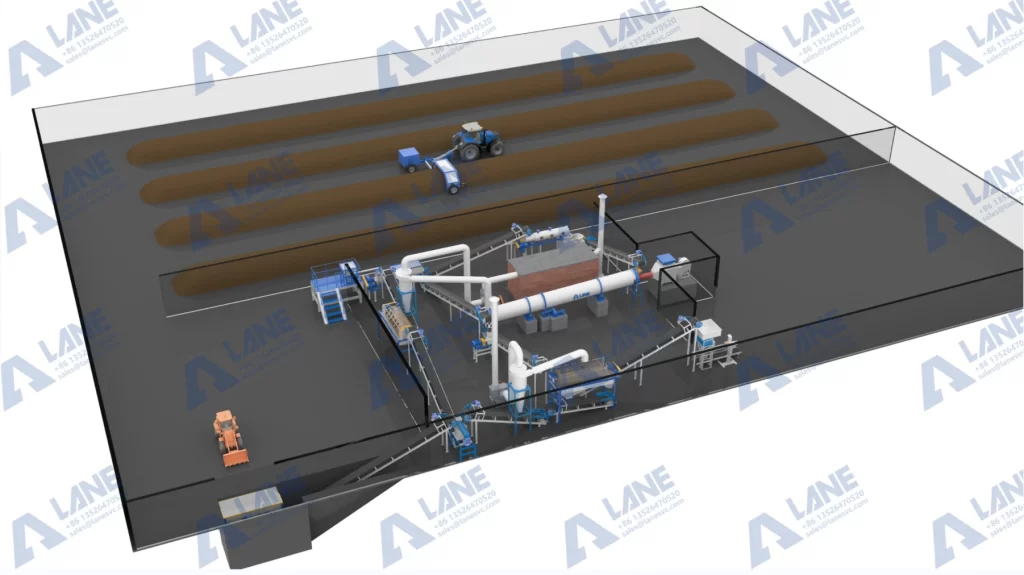

Setting up a successful organic fertilizer operation requires a tailored approach based on the primary raw materials. While the specifics may vary, the core process of a complete Eco-Friendly Organic Fertilizer Production Line follows key stages:

Organic fertilizer is a multi-purpose fertilizer which has benefits that extend far beyond simple nutrient delivery. Scientific research consistently shows that organic amendments improve soil ecology and structure.

Investing in an Eco-Friendly Organic Fertilizer Production Line is a strategic decision considering market trends and operational efficiency.

Beyond soil health, LANE’s Eco-Friendly Organic Fertilizer Production Line delivers significant profit benefits for users, making it a smart investment for agricultural businesses. First, the Eco-Friendly Organic Fertilizer Production Line reduces input costs by utilizing low-cost or free organic waste as raw materials, eliminating the need to purchase expensive chemical fertilizers. Second, the high-quality organic fertilizer produced by the Eco-Friendly Organic Fertilizer Production Line commands a premium price in the market, as consumers increasingly prioritize organic, chemical-free produce. Third, the Eco-Friendly Organic Fertilizer Production Line is highly efficient and automated, reducing labor costs and increasing production capacity.

Q1: What raw materials can I use with this production line?

A: A versatile Eco-Friendly Organic Fertilizer Production Line can process a wide range of materials, including cow/poultry manure, crop straw, food processing waste (like cocoa pods or soybean dregs), and even shellfish shells. LANE can customize the line design based on your most abundant local waste resources.

Q2: Is the fermentation process prone to odors?

A: Properly managed aerobic fermentation using professional compost turners minimizes odors. The turner ensures adequate oxygen flow, which promotes efficient decomposition by aerobic microbes and prevents the anaerobic conditions that cause strong foul smells.

Q3: What is the typical investment payback period?

A: The payback period depends on scale, raw material cost, product price, and operational efficiency. With strong market demand and efficient production, many operations can see a compelling return on investment. Detailed financial analysis is part of the project planning process.

Q4: Can you help with installation in my country?

A: Yes. LANE provides comprehensive turnkey project services, including sending engineers for overseas installation, commissioning, and training your staff to ensure smooth operation.

Q5: How does organic fertilizer compare to chemical fertilizer in terms of yield?

A: While chemical fertilizers provide immediate nutrients, organic fertilizers build long-term soil health, which leads to more sustainable and resilient yields. Research shows that integrated use of organic amendments with reduced chemical fertilizer can match or even increase yields while significantly improving soil quality and resource use efficiency.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520