In every fertilizer production line, one piece of equipment plays a critical role in ensuring uniform quality — the fertilizer mixer.

Whether for organic, compound, or bulk blending (BB) fertilizer, a reliable fertilizer mixer guarantees that nutrients are evenly distributed, preventing segregation and improving product consistency.

Among the most commonly used types are the double shaft mixer, horizontal mixer, and BB fertilizer mixer.

Each type serves specific purposes depending on the raw materials, production scale, and mixing requirements.

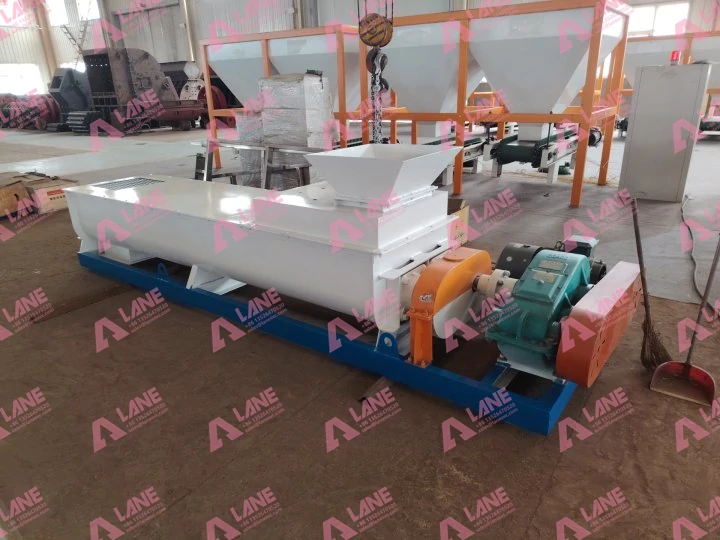

The double shaft mixer (also known as a twin-shaft mixer) is one of the most efficient machines for blending powdery or granulated materials.

It consists of two parallel shafts equipped with paddles that rotate in opposite directions, creating a continuous flow and a high-speed shearing effect.

Working Principle:

As the two shafts rotate, raw materials like compost, manure powder, or chemical granules are lifted and thrown in different directions, ensuring quick and uniform mixing.

Key Features of the Double Shaft Fertilizer Mixer:

Fast and uniform mixing: Ideal for fertilizer production lines requiring high efficiency.

Continuous operation: Can be integrated into automatic production systems.

Handles multiple materials: Suitable for organic, compound, and feed production.

Durable design: Made of wear-resistant steel for long service life.

Applications:

The double shaft fertilizer mixer is commonly used in organic fertilizer production lines, where composted materials need thorough mixing before granulation.

It’s also suitable for blending additives such as bio-agents, trace elements, or humic acid.

Because of its robust structure and fast operation, the double shaft mixer is often chosen for medium- to large-scale fertilizer plants.

The horizontal mixer is another popular type of fertilizer mixer, known for its simplicity, high efficiency, and versatility.

It uses a horizontal rotor with multiple paddles or ribbons that move materials along the barrel in a spiral pattern, ensuring even blending without dead angles.

Working Principle:

Raw materials enter the U-shaped mixing chamber, where paddles rotate at high speed, pushing the material forward and backward.

The countercurrent motion quickly disperses and homogenizes powders or granules.

Advantages of the Horizontal Fertilizer Mixer:

Uniform blending: Especially effective for fine powders and light materials.

Energy efficient: Requires less power compared to vertical mixers.

Easy to clean and maintain: Ideal for fertilizer plants that switch formulas frequently.

Compact structure: Space-saving and easy to install.

Applications:

The horizontal fertilizer mixer is widely used in compound fertilizer production lines and organic fertilizer blending processes.

It ensures that materials like urea, phosphate, and organic matter are evenly combined before granulation.

LANE’s horizontal mixers are designed with automatic discharge systems and stainless-steel interiors, preventing material buildup and cross-contamination — crucial for maintaining consistent fertilizer quality.

The BB fertilizer mixer (bulk blending mixer) is specifically designed for the BB fertilizer production line, where different finished fertilizers are blended together to create customized nutrient formulas.

Unlike other mixers that combine raw powders before granulation, the BB fertilizer mixer handles granular materials after production, mixing them gently to prevent particle damage and nutrient segregation.

Working Principle:

The system typically includes a feeding unit, lifting mechanism, and mixing drum.

Granular fertilizers such as NPK, ammonium sulfate, or potassium chloride are fed into the drum and rotated continuously until evenly mixed.

Features of the BB Fertilizer Mixer:

Gentle mixing: Prevents breakage of fertilizer granules.

Accurate blending ratio: Ensures customized formulations for different soil needs.

High automation: PLC-controlled weighing and batching for precise operation.

Large output: Suitable for industrial-scale fertilizer blending plants.

Applications:

The BB fertilizer mixer is ideal for producing customized compound fertilizers, especially for large agricultural regions that require specific nutrient ratios.

It’s a preferred choice for fertilizer distributors who offer tailor-made nutrient solutions for local crops and soils.

Choosing the Right Fertilizer Mixer

When selecting a fertilizer mixer, consider the following factors:

Material type: Powder, granules, or semi-wet compost

Production capacity: Small farm-scale or industrial plant

Mixing uniformity requirement: High precision vs. general blending

Automation level: Manual, semi-automatic, or PLC-controlled system

Double shaft mixers are best for heavy, moist materials.

Horizontal mixers suit dry powders or compound fertilizers.

BB fertilizer mixers specialize in post-granulation blending.

Combining the right fertilizer mixer with other equipment — such as granulators, dryers, and packaging machines — ensures a complete, efficient production system.

Advantages of Using Fertilizer Mixers in Production Lines

Improved Nutrient Balance: Ensures each granule or batch has a consistent nutrient ratio.

Enhanced Product Quality: Prevents segregation and caking.

Higher Efficiency: Reduces manual labor and time consumption.

Custom Formulation: Enables flexible nutrient combinations for different crops.

Scalable Design: Mixers can be customized for 1–20 T/H production lines.

In modern agriculture, precision and uniformity define product quality.

That’s why the fertilizer mixer has become a fundamental piece of equipment in every organic and compound fertilizer production line.

Conclusion

A fertilizer mixer is more than a machine — it’s the heart of any fertilizer production process.

Whether you’re operating a small organic fertilizer plant or a large compound fertilizer factory, choosing the right double shaft mixer, horizontal mixer, or BB fertilizer mixer ensures better efficiency, consistency, and profitability.

As fertilizer production technology continues to advance, modern mixers are becoming smarter, faster, and more adaptable — empowering farmers and manufacturers to deliver better fertilizers for a greener, more sustainable future.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520