As agriculture moves toward industrialization and sustainability to provide food for 8 billion people, the fertilizer processing lines has become a cornerstone of modern farming. It transforms raw synthetic or organic materials into efficient nutrients for crops. The transformation of the raw nutrient into effective, market-ready fertilizers is a complex task. It depends on the investment in the right fertilizer processing lines.

Henan LANE Heavy Industry Machinery Technology Co., Ltd is a professional manufacturer with over 20 years of experience. We offer tailored solutions for three core types of lines: granular, powder, and liquid. Each type of those fertilizer Processing lines addresses different needs and advantages of agriculture.

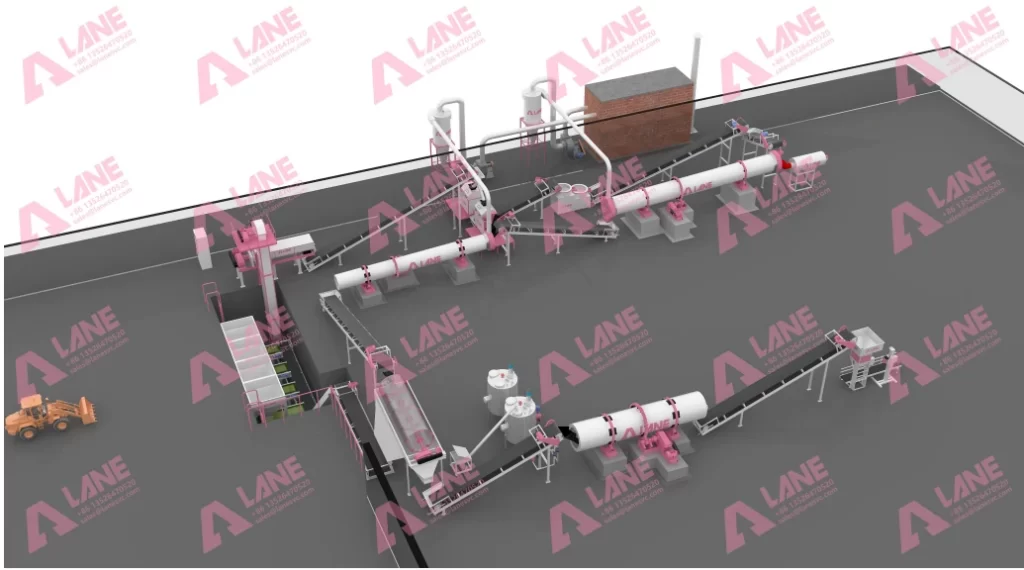

Granular fertilizer is the most common solid form of fertilizer available. They are popular for their ease of handling, storage, and slow-release properties. A complete granular fertilizer processing lines is a system designed to transform powdered raw materials into uniform, dust-free granules.

The core process typically involves:

Batching machine: LANE Dynamic batching machine is equipped with a weighting scale and sensors to accurately dispatch raw material into the production line.

Crushing & Mixing: Raw material is first crushed and mixed together with a LANE article crusher and LANE horizontal mixer.

Granulation: This is the heart of the production line. LANE Heavy Industry offers advanced granulation equipment like rotary drum granulators for high-volume NPK production, a stirring pin granulator for Organic fertilizer production, and a two-in-one new type rotary stirring pin granulator for Compound fertilizers.

Drying & Cooling: After granulation, newly formed granules are dried in the LANE rotary dryer to achieve optimal hardness. Then they are sent to the LANE Rotary Cooler to solidify their structure.

Screening & Coating: After drying and cooling, the granules are sent to the screening machine where the on-size granules are moved to the packing machine and off-size particles are sent to the crusher to reenter the production line.

A final coating polish with the LANE rotary Coating machine improves appearance and prevents caking.

The key advantage of a granular fertilizer processing lines is its product versatility. It can produce complex compound fertilizers with specific nutrient ratios, organic granules from compost, and bio-organic blends. Production lines created by LANE emphasize energy efficiency and high output. It ensures a dense, durable product suitable for mechanical broadcast spreading.

A powder fertilizer processing line offers a straightforward and cost-effective solution for organic amendments, soil conditioners, or direct powder blends. This line type provides efficient grinding, homogenization, and packaging.

The primary stages include:

A powder fertilizer processing line has lower initial capital and energy requirements. It is best for someone who just wants to start a fertilizer business with low capital and scale the business to a granular line. It is ideal for producing bulk organic fertilizer, powdered lime, or single-nutrient fertilizers like powdered phosphate. The end product is perfect for local farming use, soil blending operations, or as an intermediate for further granulation.

Liquid fertilizers, including soluble concentrates and suspensions, are becoming popular day by day. They have high absorption rates and have compatibility with irrigation systems. A liquid fertilizer processing line focuses on dissolution, reaction, and homogeneous blending.

The production process involves:

LANE Heavy Industry specializes in manufacturing corrosion-resistant tanks, reaction kettles, mixing tanks, precision metering pumps, and automated control systems essential for a consistent and high-quality liquid fertilizer processing line.

Selecting between granular, powder, or liquid fertilizer processing lines depends on your target market, investment scale, and raw material availability.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520