When people talk about modern animal feed factories, the Green feed pellet production line often comes up as a smart and eco-friendly solution. It sounds very technical, but if you break it down, it is really about turning common agricultural materials into neat, nutritious pellets using a series of well-designed machines. I find this topic interesting because it mixes science, machinery, and everyday farming needs in a very practical way.

Before any machine starts running, everything begins with raw materials. In a typical Green feed pellet production line, the most common ingredients are corn, soybean meal, wheat bran, rice husk, and sometimes additives like vitamins or minerals. Corn provides energy, soybean meal offers protein, and wheat bran helps with fiber. These materials are easy to find and widely used, which makes the whole process economical and realistic for many feed producers.

However, these raw materials cannot be used directly. They usually arrive in different shapes, sizes, and moisture levels. Some may contain impurities like stones, dust, or metal pieces. That is why pre-treatment is so important. First, screening equipment removes large impurities. Then magnetic separators are used to catch metal parts, protecting downstream machines. After that, raw materials are stored in silos or bins where they can be evenly fed into the next stage. This careful preparation ensures that the final pellets are safe, uniform, and stable in quality.

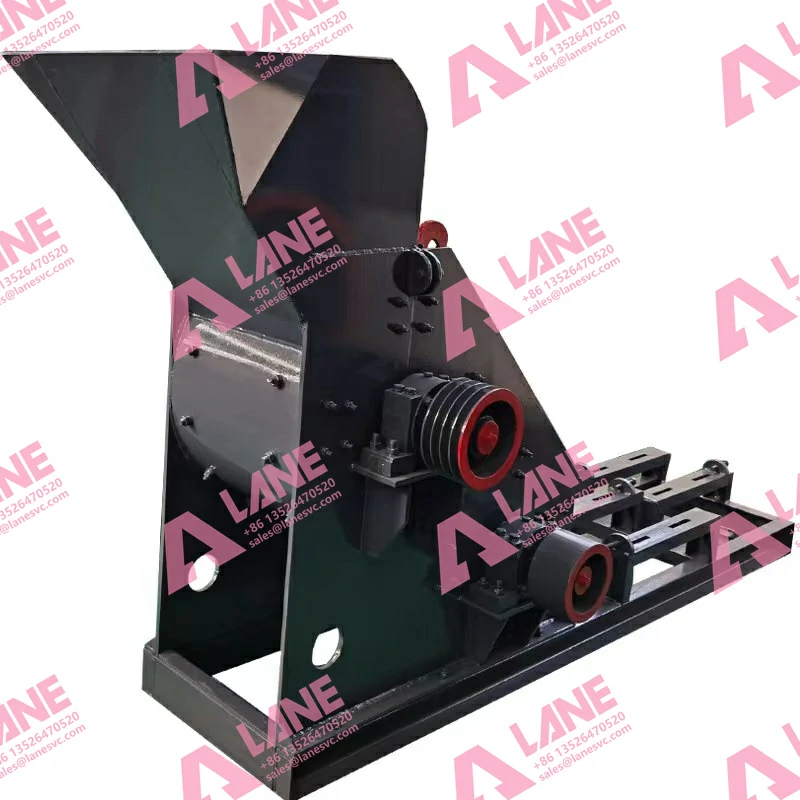

Once the raw materials are clean, they move to the crushing section. In the Green feed pellet production line, a hammer crusher is usually used. The main job of this machine is to reduce large particles into fine powder. This might sound simple, but it plays a huge role in pellet quality.

The double shaft crusher uses high-speed rotating hammers to hit the materials repeatedly until they are small enough to pass through a screen. Different screen sizes can be chosen depending on the animal feed type. For example, poultry feed usually needs finer particles, while cattle feed can be a bit coarser. The technical advantage of modern grinders is their adjustable structure, stable operation, and high efficiency. A well-crushed material mixes better and forms stronger pellets later on.

After crushing, materials enter the mixing stage. In a Green feed pellet production line, mixers ensure that every pellet contains the same nutritional formula. This is especially important when small amounts of additives are involved.

Horizontal ribbon mixers or paddle mixers are commonly used. They work by rotating internal blades that push materials in different directions, creating a uniform blend. Technically speaking, good mixers have short mixing times, low residue, and easy cleaning. From a practical point of view, they save time and reduce waste. Even mixing also helps the pellet mill run smoothly, which improves overall production efficiency.

The heart of the Green feed pellet production line is the pelletizing machine, and one popular choice is the flat die pellet mill. This machine transforms powder into solid pellets by applying pressure and friction.

Inside the flat die pellet mill, rollers press the mixed material through small holes in a flat die. As the material is squeezed out, it forms cylindrical pellets. The heat generated during this process helps starch gelatinize, which improves pellet hardness and digestibility. Technically, flat die pellet mills are known for their simple structure, easy operation, and suitability for small to medium-scale production. They are also easier to maintain, which makes them attractive to many feed producers.

Fresh pellets coming out of the pellet mill are hot and slightly moist. If they are packed immediately, they may break or grow mold. That is why drying and cooling are essential parts of the Green feed pellet production line.

A dryer reduces moisture content by circulating warm air around the pellets. This step improves shelf life and prevents spoilage. After drying, a cooler lowers the pellet temperature to match room conditions. From a technical perspective, modern dryers and coolers are designed to control airflow and temperature precisely. This prevents over-drying, which could cause nutrient loss. These machines help pellets stay firm, clean, and easy to transport.

After cooling, pellets usually pass through a rotary screener. This removes broken pellets and fine powder, which can be recycled back into the system. This small step improves the final appearance and quality of the product.

Packaging machines are the last stop in the Green feed pellet production line. They weigh and pack pellets into bags of different sizes. Automatic packaging systems are accurate and fast, reducing labor costs and human error. In a real factory, this stage gives the first visual impression of product quality, so it is more important than it seems.

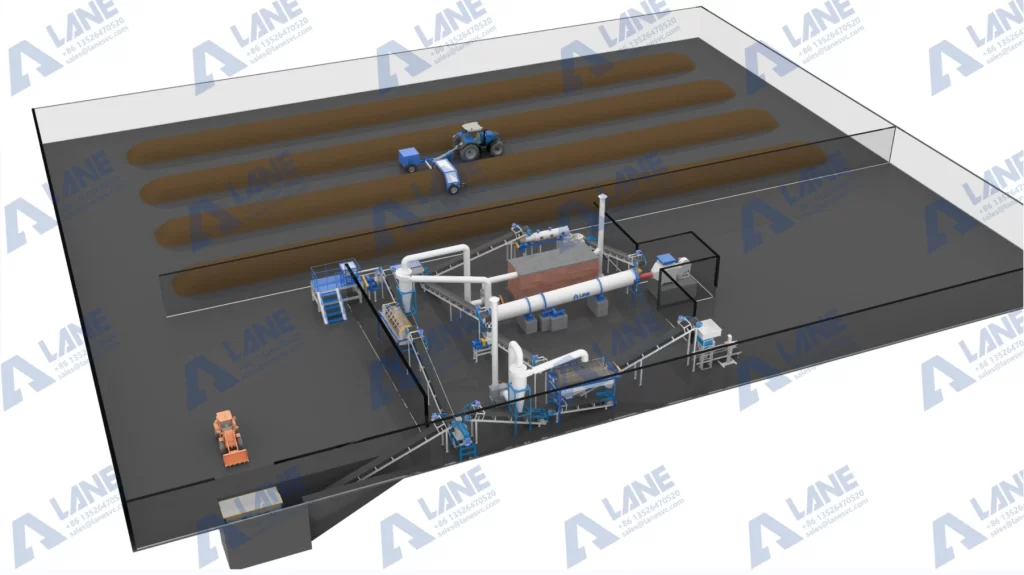

What makes the Green feed pellet production line special is not just each individual machine, but how they work together as a system. From raw material intake to final packaging, every step is connected. Conveyors, bucket elevators, and control systems link the machines smoothly.

Automation is another technical highlight. With a central control panel, operators can monitor temperature, motor load, and production rate. This makes the line safer and easier to manage. Even someone with basic training can understand the process, which is why this technology is spreading so fast in modern agriculture.

As part of this industry, our company has grown alongside the development of the green feed pellet production line. At LANE, we have been working in machinery manufacturing for more than 20 years. We design and build complete production lines, supported by our professional engineering team. We follow ISO 9001 and CE standards, and we focus on reliable equipment and long-term service. For us, helping customers keep their lines running smoothly is just as important as selling machines.

The Green feed pellet production line represents a balance between technology and sustainability. It helps farmers use resources wisely while producing consistent, high-quality feed. As technology improves, these lines will become even more efficient, smarter, and more environmentally friendly. For students like me who enjoy seeing how machines shape daily life, this production line is a great example of practical engineering at work.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520