The Growing Importance of Hen Manure Compost

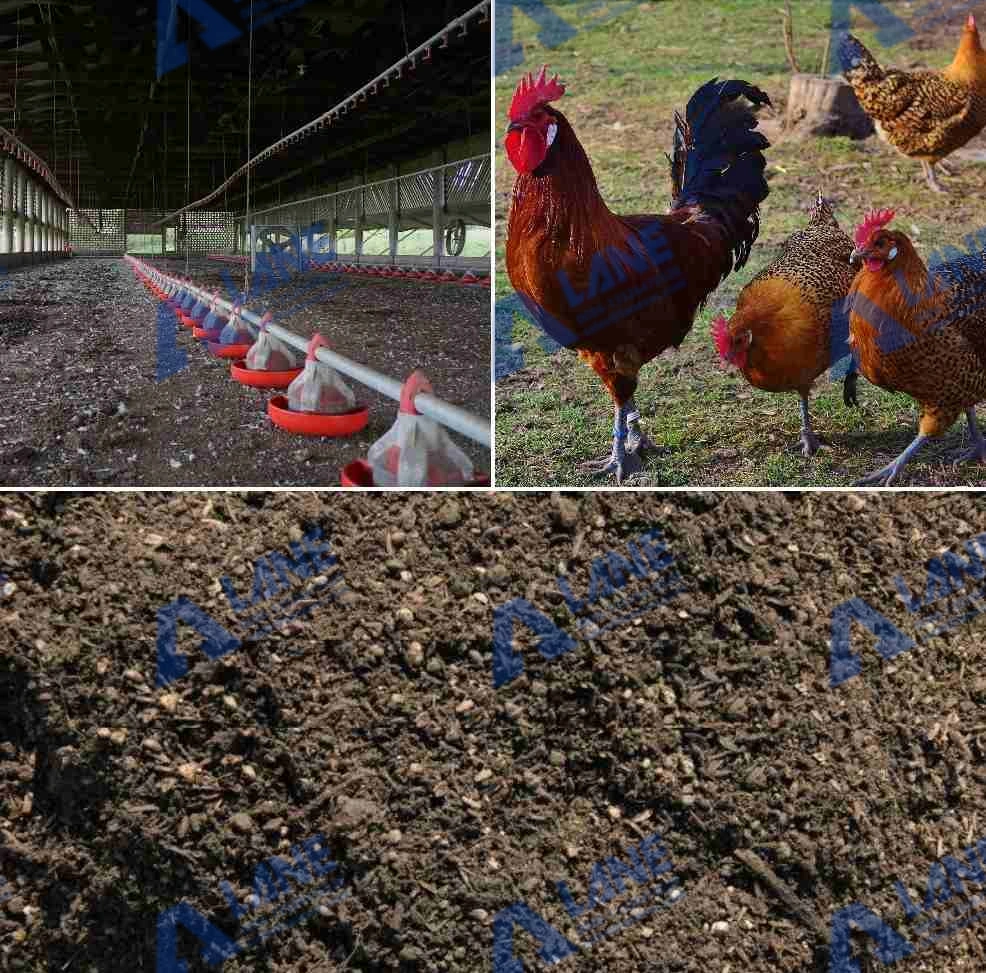

Hen manure compost has become a cornerstone of sustainable agriculture in recent years. As poultry farming expands globally, large amounts of chicken or hen manure are produced daily. If untreated, this waste can cause environmental problems—unpleasant odors, groundwater pollution, and greenhouse gas emissions. However, with proper composting technology, hen manure can be converted into nutrient-rich organic fertilizer, improving soil fertility and crop productivity while reducing environmental impact.

Modern composting systems, such as crawler type compost turners, aerated composting tunnels, and organic fertilizer production lines, allow farms and fertilizer producers to process tons of manure efficiently. Companies like LANE Heavy Industry are helping poultry farms worldwide establish customized composting solutions that turn waste into value.

What Is Hen Manure Compost?

Hen manure compost is the result of aerobic decomposition of poultry waste, where microorganisms break down organic matter under controlled conditions—oxygen, moisture, and temperature—to produce a stable, humus-like material rich in nutrients.

Fresh hen manure contains high levels of nitrogen (N), along with phosphorus (P) and potassium (K)—the essential macronutrients for plant growth. However, raw manure is too strong to apply directly to crops due to its high ammonia content and potential pathogens. Composting stabilizes these nutrients and eliminates harmful bacteria, resulting in safe and effective organic fertilizer.

Nutrient Composition of Hen Manure Compost

| Nutrient | Average Content (%) | Function |

| Nitrogen (N) | 2.0 – 4.0 | Promotes leafy growth and protein synthesis |

| Phosphorus (P₂O₅) | 1.5 – 3.0 | Enhances root development and flowering |

| Potassium (K₂O) | 1.0 – 2.0 | Improves fruiting and disease resistance |

| Organic Matter | 30 – 50 | Improves soil texture and microbial activity |

| Moisture | 25 – 35 | Ensures microbial survival and stability |

This balanced composition makes hen manure compost an excellent organic amendment for both vegetable fields and orchards, as well as for land rehabilitation projects.

The Composting Process of Hen Manure

The process of making hen manure compost involves several key stages, each requiring proper control of environmental parameters.

1.Material Preparation

Collect fresh hen manure from poultry houses and mix it with carbon-rich materials (such as straw, sawdust, or rice husk) to balance the carbon-to-nitrogen (C/N) ratio between 25:1 and 30:1. Adjust moisture content to 55–60% for optimal microbial activity.

2.Pile Formation

Pile the materials into long windrows or compost heaps. The size of the pile depends on the available space and compost turner type—typically 2.5–3 meters wide and 1.2–1.5 meters high.

3.Aerobic Fermentation and Turning

Use a crawler type compost turner or wheeled compost turner to regularly flip the pile, ensuring sufficient oxygen supply and even heat distribution. The temperature should rise to 55–65°C, which helps destroy pathogens, weed seeds, and parasites.

4.Cooling and Maturation

After 15–25 days, the temperature gradually drops as the material stabilizes. This maturation phase allows beneficial microbes to convert complex compounds into humus.

5.Screening and Storage

Once the compost becomes dark brown and earthy in smell, it can be screened to remove large particles and stored for use or further processed into granules.

Equipment Used in Hen Manure Compost Production

| Process Step | Equipment | Function |

| Mixing | Vertical mixer or horizontal mixer | Ensures uniform combination of manure and carbon materials |

| Turning | Crawler or wheeled compost turner | Aerates the pile and speeds up decomposition |

| Crushing | Compost crusher | Breaks down large chunks after fermentation |

| Screening | Rotary drum screener | Separates fine compost from coarse residues |

| Granulation (optional) | Disc or drum granulator | Produces uniform organic fertilizer pellets |

| Drying & Cooling | Rotary dryer and cooler | Reduces moisture for long-term storage |

| Packaging | Automatic packing machine | Prepares compost for sale or distribution |

LANE Heavy Industry provides full organic fertilizer production line solutions, including these machines with customized capacities from 1 to 20 tons per hour, ensuring efficient and safe processing of hen manure compost.

Advantages of Hen Manure Compost

1.Environmentally Friendly Waste Management

Composting hen manure reduces methane and ammonia emissions while preventing nutrient leaching into water sources. It’s an eco-friendly alternative to raw manure disposal.

2.High Nutrient Efficiency

Composted hen manure releases nutrients gradually, improving soil fertility over time and reducing the need for synthetic fertilizers.

3.Enhanced Soil Health

The organic matter improves soil structure, increases microbial diversity, and enhances water-holding capacity—particularly valuable for sandy or degraded soils.

4.Cost-Effective Solution for Poultry Farms

Instead of spending money on waste disposal, farms can turn manure into marketable organic fertilizer, creating an additional revenue stream.

5.Compliance with Environmental Regulations

Many countries now have stricter laws regarding manure management. Composting ensures compliance with pollution control standards.

Case Study: Hen Manure Composting Project in the Philippines

The Philippines, a nation with a rapidly growing poultry sector, faces increasing challenges in managing organic waste from its farms. According to the Department of Agriculture, the country produces over 1 million tons of poultry manure annually, especially from large layer and broiler operations concentrated in regions like Central Luzon, Batangas, and Mindanao. Without proper treatment, this waste can contribute to serious environmental problems such as groundwater contamination and odor emissions.

In 2024, LANE Heavy Industry collaborated with a Philippine agribusiness company based in Bulacan Province to establish a 4–5 tons per hour hen manure composting production line. The project’s goal was to convert chicken manure from multiple poultry houses into marketable organic fertilizer for local vegetable and fruit growers.

Before implementing the composting system, the farm had been stockpiling raw manure in open pits. This not only emitted strong ammonia odors but also attracted flies and led to nutrient loss during the rainy season.

The key challenges included:

Limited space for large-scale composting

High moisture content (above 70%) in fresh manure

Need for quick turnaround due to continuous manure generation

Strict environmental compliance under local LGU regulations

To overcome these issues, the farm decided to build a semi-enclosed composting facility equipped with modern machinery designed for tropical climates.

System Design and Equipment Configuration

LANE’s engineering team proposed a compact yet efficient composting system that fits within a 2,000 m² site while maintaining high throughput.

The key equipment included:

| Equipment | Model | Function |

| Crawler Type Compost Turner | LANE CT-3000 | For daily turning and aeration of compost piles |

| Horizontal Mixer | LANE HM-50 | For pre-mixing chicken manure with rice husk and sawdust |

| Vertical Crusher | LANE CC-800 | To break down large clumps post-fermentation |

| Rotary Drum Screener | LANE RS-1200 | For separating fine compost and oversized materials |

| Stirring pin Granulator | LANE DG-1800 | Optional stage for making granular organic fertilizer |

| Automatic Packaging Machine | LANE PM-50 | For weighing and bagging finished compost |

The system also included an aeration and leachate collection setup to manage odor and prevent runoff contamination, aligning with Philippine environmental standards.

Composting Process and Operation

Raw Material Preparation:

Chicken manure was collected daily and mixed with locally available bulking agents such as rice husk and coconut coir dust, balancing the carbon-to-nitrogen ratio to around 28:1.

Fermentation Stage:

Windrows were formed approximately 2.5 meters wide and 1.2 meters high, and the crawler type compost turner was used every two days to maintain aerobic conditions.

The compost reached 60°C within 48 hours, effectively eliminating pathogens and fly larvae.

Maturation and Screening:

After about 25 days, the compost temperature stabilized below 40°C, indicating maturity. The material was then screened and stored in shaded curing areas.

Packaging and Distribution:

The final product was packed in 25-kg and 50-kg bags, branded as “EcoGrow Organic Fertilizer”, and distributed to nearby vegetable farms in Nueva Ecija and Benguet.

Results and Benefits

After six months of operation, the farm achieved significant improvements in waste management and profitability:

| Indicator | Before Project | After Project |

| Odor and Fly Infestation | Severe | Minimal |

| Waste Disposal Cost | ₱1.2 million/year | Eliminated |

| Fertilizer Output | None | 3,000 tons/year |

| Profit Margin | — | 15–20% net profit |

| Payback Period | — | 1.5 years |

Nutrient analysis of the compost revealed:

Nitrogen (N): 3.1%

Phosphorus (P₂O₅): 2.4%

Potassium (K₂O): 1.6%

Organic Matter: 45%

These nutrient levels made it highly suitable for banana, corn, and vegetable cultivation—key agricultural sectors in the Philippines.

FAQs About Hen Manure Compost

Q1: How long does it take to produce hen manure compost?

Typically, 20–30 days depending on temperature, moisture, and equipment efficiency.

Q2: Can composting eliminate the smell of manure?

Yes. Proper aeration and turning reduce odor significantly within the first week.

Q3: Can I mix hen manure with other materials?

Absolutely. Mixing with crop residues, straw, or sawdust improves compost structure and C/N balance.

Q4: What equipment is necessary for small-scale composting?

A wheeled compost turner or even a small crawler-type model is enough for farms under 500 m².

Q5: Is composted hen manure safe for organic farming?

Yes, if processed correctly and without chemical additives, it fully meets organic certification standards.

Economic Perspective: Turning Waste into Profit

Using hen manure compost can reduce fertilizer costs by 30–40%, while selling the finished product provides new income opportunities.

For example, in Southeast Asia, high-quality compost sells for $100–150 per ton, while raw manure disposal can cost farms thousands annually.

Investing in a LANE composting line enables poultry producers to move from waste management to value-added fertilizer production, increasing profitability and sustainability simultaneously.

A Circular Future with Hen Manure Compost

The development and application of hen manure compost represent a crucial step toward sustainable agriculture. It solves waste management issues, enriches the soil, and supports eco-friendly farming practices.

With advanced composting machinery and years of engineering experience, LANE Heavy Industry helps farms and fertilizer producers design efficient composting systems—turning poultry waste into high-quality organic fertilizer ready for global markets.

From backyard farms to industrial-scale facilities, the message is clear: hen manure compost is not just waste management—it’s soil restoration, economic opportunity, and environmental responsibility rolled into one.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520