As global demand for sustainable agriculture continues to grow, organic fertilizer production is becoming increasingly equipment-driven. Stable output and consistent product quality now depend heavily on efficient pre-processing systems. A High-Efficiency Organic Fertilizer Crusher plays a critical role in converting raw organic waste into uniform, process-ready material that supports smooth fermentation and downstream granulation.

Our professional crushing solutions are designed to handle complex organic materials such as livestock manure, crop straw, sludge, and food waste, helping fertilizer producers improve efficiency while reducing maintenance risks.

Raw organic materials are rarely suitable for direct processing. Large clumps, fibrous residues, and uneven particle sizes can damage equipment and severely limit fermentation performance. A High-Efficiency Organic Fertilizer Crusher solves these problems by breaking down materials into consistent particles, increasing surface area and creating optimal conditions for microbial activity.

This step directly impacts fermentation speed, granulation stability, and final fertilizer quality.

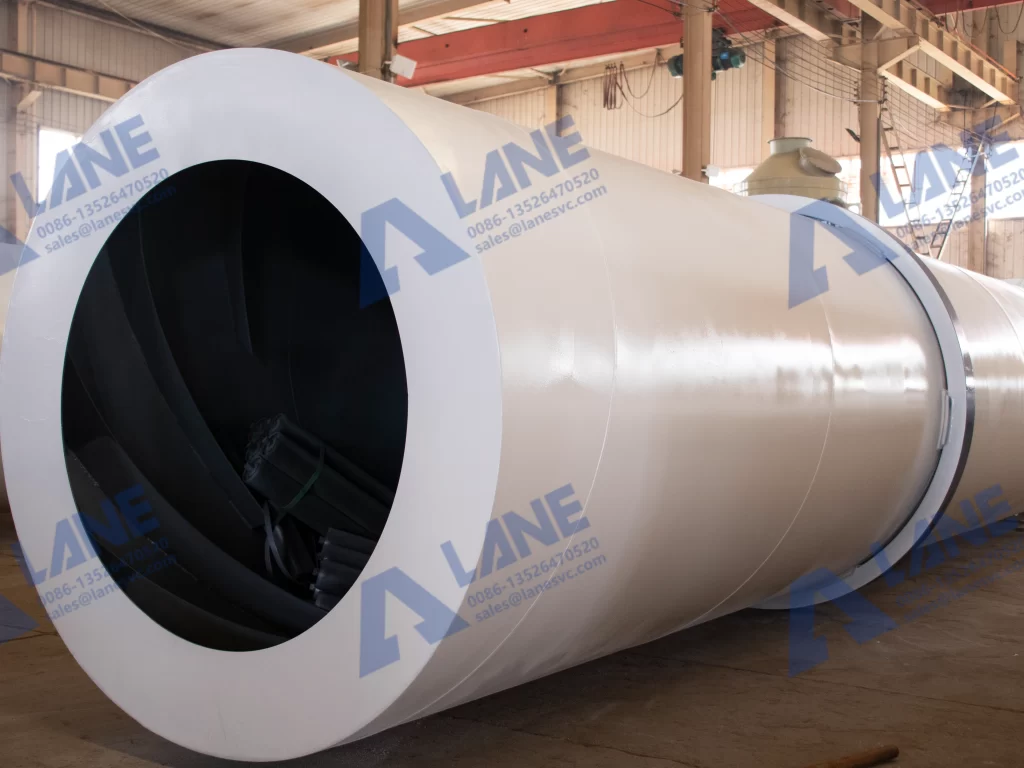

Our High-Efficiency Organic Fertilizer Crusher is engineered with a heavy-duty rotor, wear-resistant hammer blades, and reinforced liners. It efficiently processes:

High-moisture livestock manure (chicken, cow, pig)

Fibrous agricultural waste such as corn stalks and rice straw

Sludge, food waste, and organic industrial residues

Its advanced anti-clogging structure ensures continuous operation even under high moisture conditions, minimizing downtime and maintenance frequency.

Different production scenarios require different crushing solutions:

All configurations can be optimized to meet specific capacity and particle size requirements.

Material enters the crushing chamber and is impacted repeatedly by high-speed rotating hammers. Once particles reach the target size, they pass through the screen or discharge system. For high-humidity materials, optional screenless designs eliminate clogging entirely.

Key components use high-manganese or alloy steel with special heat treatment, extending service life by up to 50% compared with conventional crushers. This makes the High-Efficiency Organic Fertilizer Crusher a reliable core unit in continuous production lines.

Q1: How does the crusher handle wet materials?

Through optimized airflow design, wide discharge gaps, and optional screenless structures, wet materials are processed without blockage.

Q2: How often are wear parts replaced?

Hammer blades typically last 300–800 operating hours depending on material abrasiveness and are easy to replace.

Q3: How do I select the right model?

Capacity, raw material characteristics, and discharge size determine the optimal configuration. Technical consultation is recommended.

In an ecological agriculture park in East China, a High-Efficiency Organic Fertilizer Crusher was integrated into a 5 t/h production line processing chicken manure and straw. The system achieved stable output, reduced maintenance costs, and significantly improved fertilizer uniformity, earning strong customer recognition.

A High-Efficiency Organic Fertilizer Crusher is not just a crushing machine—it is the foundation of a stable, efficient, and profitable organic fertilizer production line. With advanced anti-clogging design, long service life, and strong material adaptability, it ensures smooth operation from fermentation to granulation.

Choosing a reliable crusher means choosing higher efficiency, lower risk, and long-term production stability.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520