Introduction: Turning Waste into Wealth

The demand for organic fertilizer is increasing day by day. In the last few decades, farmers all over the world used too much chemical fertilizer. This made the soil quality and biodiversity of these farmlands decline significantly, increasing dependence on chemical inputs. However, years of chemical fertilizer use lead to salt accumulation in the soil and destroy beneficial microorganisms essential for healthy crops. As a result, farmers and governments are now paying more attention to sustainable agriculture practices and are actively exploring How to Build an Organic Fertilizer Production Line as a long-term solution.

Building an organic fertilizer production line represents a powerful opportunity to transform organic waste such as animal manure, agricultural residues, and food waste into valuable soil amendments. For many investors and producers, understanding How to Build an Organic Fertilizer Production Line is the first step toward sustainable fertilizer manufacturing. This guide demystifies the process by providing a clear, step-by-step blueprint on How to Build an Organic Fertilizer Production Line, from raw material processing to final product packaging. We will also highlight how machines from LANE Heavy Industry can improve efficiency, ensure stable operation, and help you produce consistent, high-quality organic fertilizer.

Step 1: Planning & Feasibility – The Foundation of Your Project

Thorough planning is part of the production process. Before you ask “How to Build an Organic Fertilizer Production Line?” you should plan your foundation.

- Define Your Raw Materials: You have to identify your primary raw material and its sources. Common raw materials for organic fertilizer include poultry/cattle manure, mushroom residue, biogas sludge, or green waste. You have to consider the consistency and carbon-to-nitrogen ratio of your feedstock. This also influences the processing stage.

- Determine Product Type: You have to make a plan about your product type. Will you produce powdered fertilizer (simpler, lower cost) or granulated fertilizer (popular for commercial sale due to easier storage, application, and reduced dust)? Or will you start with powder then scale to a granulation production line?

- Assess Scale and Budget: You have to assess your budget and the scale of the production line. Are you

- aiming for a small-scale on-farm setup (1-2 tons per hour) or a large-scale commercial plant? Your output goal will dictate the investment required for your organic fertilizer production line.

- Regulations and Market: You have to research the local demand and regulations. Analyze your potential market like neighboring farms, garden centers, or agricultural co-ops.

Step 2: Understanding the Core Production Process

The basic answer to “How to Build an Organic Fertilizer Production Line” is to follow a logical sequence to create an end product from raw material. These steps for organic fertilizer are:

- Pre-processing & Fermentation: The first sequence of organic fertilizer production focuses on raw material preparation, a critical stage when learning How to Build an Organic Fertilizer Production Line. The raw materials are sorted and adjusted for moisture content and the C/N ratio before being composted using fermentation tanks or windrow turners. Efficient fermentation is essential for killing pathogens and weed seeds while stabilizing the organic matter.

- Crushing & Screening: After fermentation, the composted materials are broken down into a fine powder to ensure smooth granulation and precise nutrient formulation. This step is often emphasized in guides on How to Build an Organic Fertilizer Production Line, as proper crushing and screening help remove non-compostable impurities such as stones and plastics.

- Mixing & Blending: The powdered compost is then mixed with additional nutrients, micronutrients, or soil amendments to create a standardized and enriched fertilizer formula, a key consideration when planning How to Build an Organic Fertilizer Production Line for consistent product quality.

- Granulation: The mixed powder is then sent to the granulation machine to be formed into uniform granules. This increases the product’s marketability.

- Drying & Cooling: Fresh granules are wet and soft. Drying reduces moisture to a storage-safe level, while cooling solidifies them.

- Screening & Packaging: Final granules are screened to separate out-of-spec product, which is recycled. The on-size granules are then weighed and packaged.

Step 3: Selecting the Right Machinery – The Heart of Your Line

This is where your organic fertilizer production line comes to life. Partnering with LANE Heavy Industry will get you an efficient and durable production line that ensures product uniformity and consistency. LANE equipment includes:

- Fermentation Equipment: A LANE Hydraulic Crawler Type Compost Turner is effective for windrow composting. It uses its hydraulic engine to turn and crush compost material. This introduces oxygen to the pile and accelerates fermentation.

- Crusher: A Semi-wet Material Crusher handles post-fermentation materials effectively. It breaks down sticky compost without clogging.

- Mixing Machine: A Horizontal Mixer ensures a homogenous blend of organic powder and additives. You can also add water to prepare it for the granulation process.

- Granulation Machine: This is the core of the granulation production line. LANE Heavy Industry offers versatile solutions for different raw materials, capacities, and price points. The most suitable for organic fertilizer is the LANE Stirring Pin Granulator. For smaller scale or feed pellets, you can use a Flat Die Pellet Mill. Choosing the right one is central to learning how to build an organic fertilizer production line for your specific product.

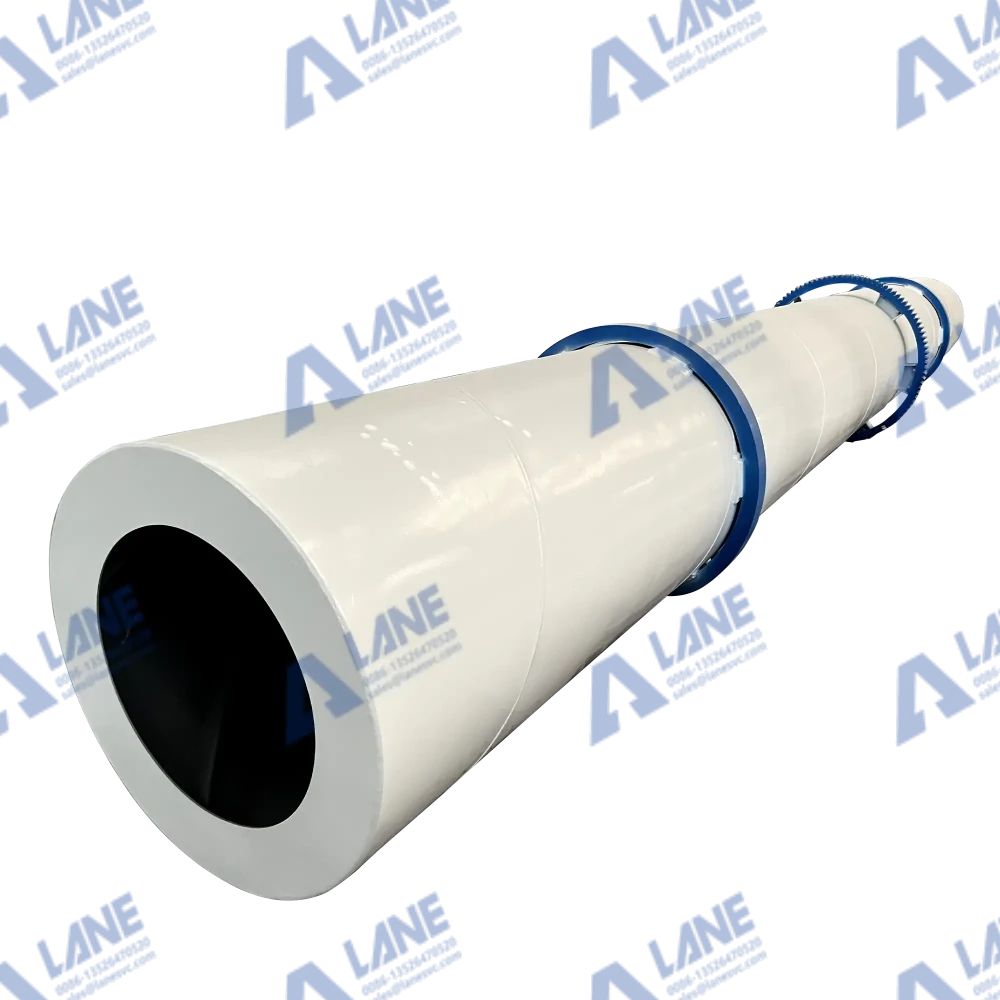

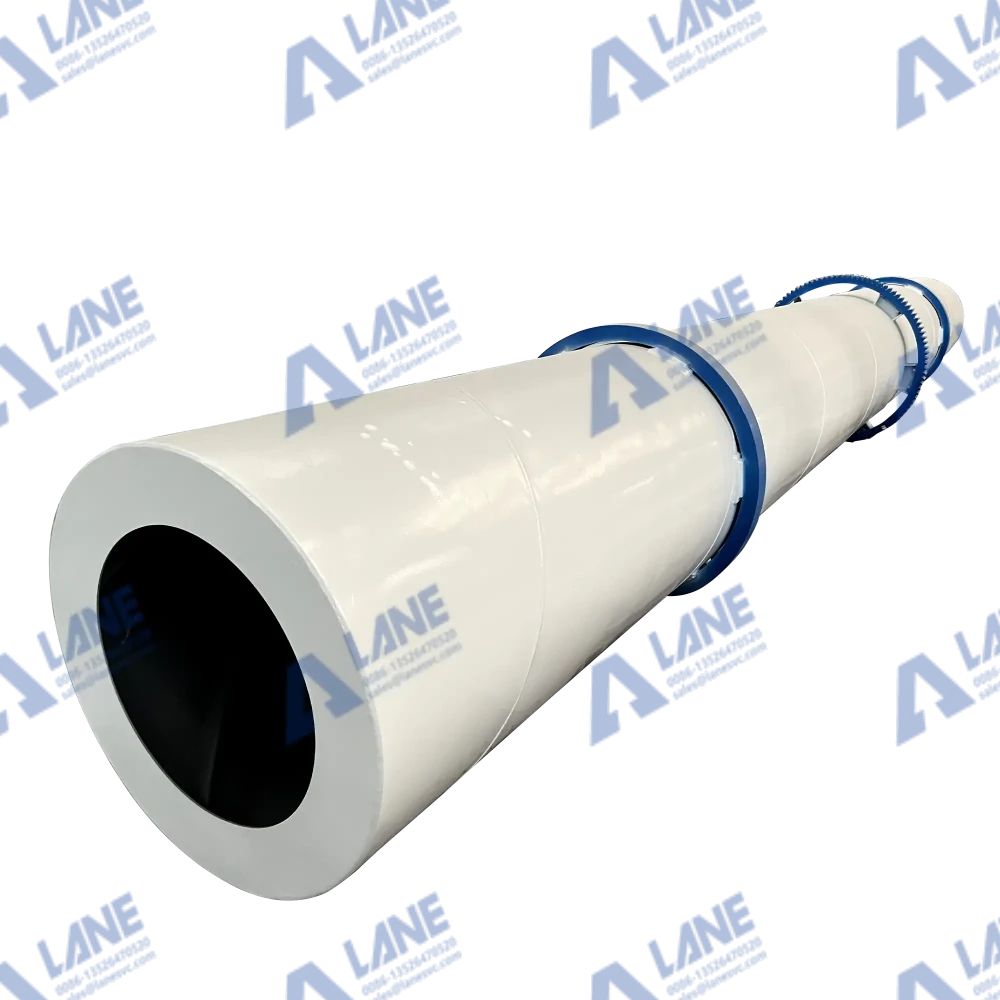

- Drying & Cooling System: A Rotary Drum Dryer paired with a Rotary Cooler efficiently handles large volumes of granules in a continuous flow.

- Screening & Packaging: A Rotary Drum Screener classifies the final product and sends it to the automatic Weighing and Packaging system where it is packaged and ready for the market.

Step 4: Plant Layout & Installation

A logical, efficient layout minimizes labor and energy costs. The machines should be arranged properly to keep space for washing and proper material flow. Ensure you have:

- Different space areas for raw material storage, fermentation platforms, production workshop, and finished product warehouse.

- Proper foundational support for heavy machinery.

- Access to power, water, and possibly gas (for dryers).

LANE provides professional design and installation service. Our engineers make sure your technicians are trained and are ready to handle the production line.

Conclusion: Building a Sustainable Future

Learning how to build an organic fertilizer production line is an investment in a greener, more circular economy. Building a production line is a systematic project that requires careful planning and strict implementation from market research, site selection, equipment selection to process design and certification application. By selecting LANE Heavy Industry as your partner, you establish a foundation for a successful venture.

Frequently Asked Questions (FAQ)

Q1: What is the minimum budget required to build a small-scale organic fertilizer production line?

A: The investment varies greatly by scale and automation level. A basic powdered fertilizer line can start from tens of thousands of dollars, focusing on a crusher, mixer, and screener. A complete granulation line, including fermentation equipment, a granulator, dryer, and cooler from a supplier like LANE Heavy Industry, represents a larger, more productive investment for commercial output.

Q2: How long does it take to build and commission a full production line?

A: From order to operation, typically 2-6 months. This includes machinery fabrication, delivery, workshop preparation (if needed), installation, and trial runs. The timeline depends on the line’s complexity and the readiness of your site.

Q3: Can I use a single granulator machine for all types of organic waste?

A: While versatile machines exist, the choice of granulator (e.g., disc granulator, new organic granulator) depends on the material’s characteristics (fibrousness, moisture, stickiness). LANE Heavy Industry can advise on the best granulation solution based on your specific raw material analysis to ensure your organic fertilizer production line runs smoothly.

Q4: Is the process environmentally friendly?

A: Absolutely. The core of the process is aerobic fermentation (composting), which is a natural biological activity. A well-designed organic fertilizer production line controls odor, prevents leachate runoff, and transforms potential pollutants (manure, waste) into a beneficial product, making it a model of environmental technology.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520