Table of Contents

In today’s world, organic fertilizer represents eco-friendly farming practices. It is made from organic raw materials like crop residues, animal manure, and food waste. However, traditional organic fertilizer production was synonymous with windrows, manually turning compost piles, and labor-intensive bagging. While this method is effective, it is time-consuming and struggles to meet the growing demand from large-scale farms and commercial agricultural operations without the support of industrial fertilizer production machines.

Scaling organic fertilizer production can only be achieved by integrating advanced automation and equipment. LANE Heavy Industry, a leader in fertilizer production machinery manufacturing, has developed a complete range of industrial fertilizer production machines designed to support efficient, large-scale organic fertilizer production for modern agricultural businesses.

The shift from manual to an industrial-scale organic production line is not about adding chemical formulations or methods. It is about applying precision engineering, controlled processes, and automation to create compost and final granules that can be applied on industrial farms.

The modern organic fertilizer production line transforms raw materials like compost, manure, peat, biochar, and plant meals into a uniform, stable, market-ready product. This allows producers to guarantee nutrient content, eliminate pathogens and weed seeds through controlled thermophilic processing. With a LANE production line you can create your own specialized organic fertilizer formulations.

LANE Heavy Industry, with 20 years of experience in the fertilizer industry, engineers machines that are durable and can adapt to abrasive organic materials. The industrial fertilizer production machines by LANE are:

Hydraulic Compost Turners: LANE crawler compost turners come in a few variants. We have powerful high-speed compost turners, remote control compost turners, and Mulching Crawler Compost turners. These machines rapidly aerate and blend compost batches, ensuring uniform bioactivity.

Horizontal Mixers: The LANE Horizontal mixer is a powerful mixer which can uniformly mix additives like rock phosphate, potassium sulfate, or beneficial microbes into the compost base. The mixing is consistent, which is impossible by hand.

Organic Fertilizer Granulators: This is the heart of the granulation operation. LANE created a new Stirring Pin granulator that can convert fine powder into uniform granules. Granules are dust-free, easy to spread, and release nutrients slowly. Granulated fertilizer has a higher market price and market share than normal dust fertilizer.

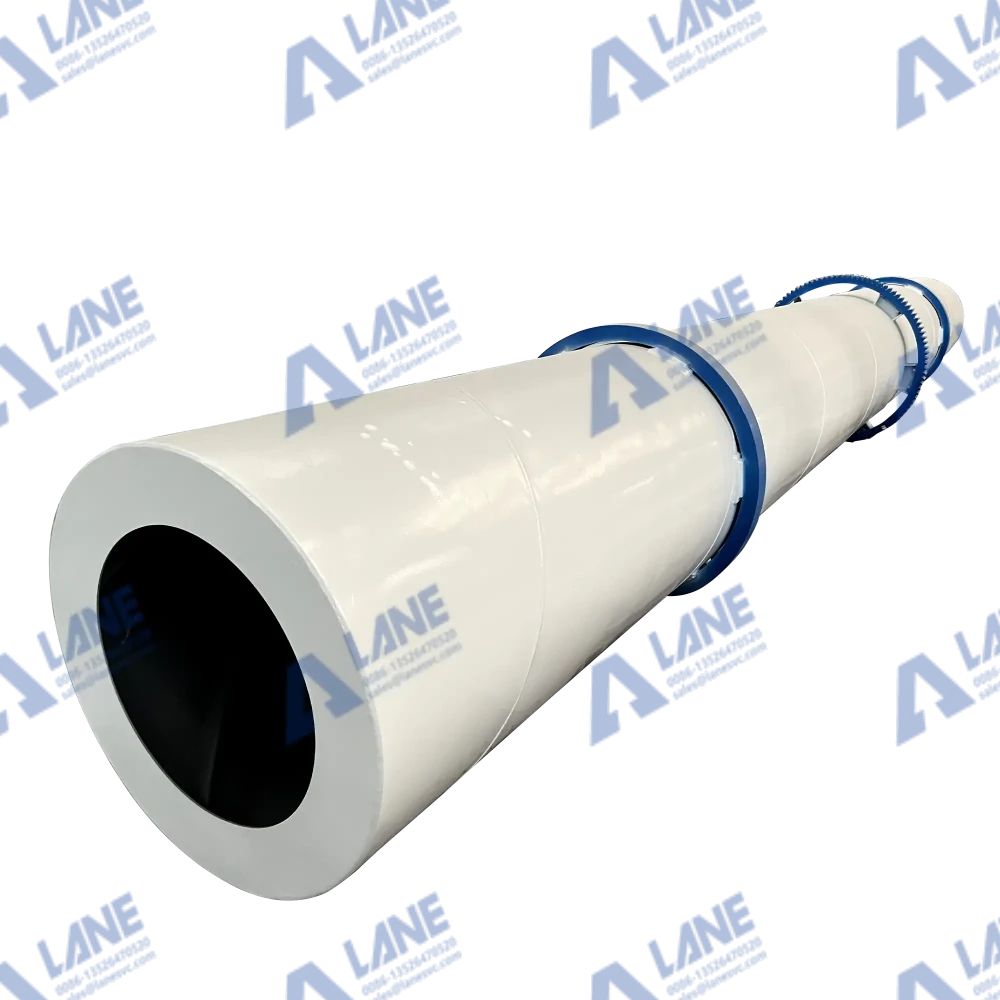

Rotary Drum Dryers & Coolers: This is critical for post-granulation processing. The LANE rotary dryer reduces moisture to a stable level. It helps prevent caking and microbial spoilage. After drying, the granules are sent to the coolers. Subsequent cooling hardens the granules for easy handling and packaging.

Rotary Screening Machines: This machine separates on-size granules from out-of-spec granules and sends them to the crusher to reenter the process. This ensures only perfectly sized product moves to packaging.

Automatic Packing Machine: This is the final step of the organic fertilizer production line. This machine automatically weighs and packs the final products.

When the industrial fertilizer production machines are synchronized, they create a seamless, continuous process flow:

Investing in a LANE Heavy Industry production line unlocks many benefits:

Q: Aren’t industrial machines only for chemical/synthetic fertilizer plants?

A:Not anymore. Manufacturers like LANE Heavy Industry now design industrial fertilizer production machines specifically for the abrasive, variable nature of organic materials. They are built with corrosion-resistant materials and adaptable designs to handle compost, manure, and other bio-based inputs.

Q: Is the final product still considered “organic” when made with this machinery?

A: Absolutely. The machinery is a processing tool, like a tractor tilling a field. It does not add synthetic chemicals. The organic certification depends on the input materials and process compliance (e.g., maintaining proper temperatures), which this equipment helps control and document more precisely.

Q: What is the biggest barrier to entry for this kind of setup?

A: The initial capital investment is significant. However, it must be analyzed as a return-on-investment calculation. The jump in production volume, product value, and operational efficiency typically leads to a compelling payback period, transforming a business from a local supplier to a regional player.

Q: Can these machines handle different formulations?

A: Yes, that is a key advantage. With a precision mixer and recipe management, switching between formulations for different crops or customer needs can be done quickly and accurately, much more so than in manual batch systems.

Q: How important is after-sales support and spare parts?

A: It is critical. Organic materials are highly abrasive and cause wear on equipment. Choosing a supplier like LANE Heavy Industry, known for robust design and readily available spare parts and service, is essential for minimizing downtime and maintaining continuous production.

Demand for organic fertilizer will continue to grow. With it, the scale of production will also need to be increased. By integrating industrial fertilizer production machines from LANE Heavy Industry, producers can scale the benefits of organics without compromising on quality. Our production line enables producers to meet the growing demand for organic fertilizer while improving efficiency, reducing costs, and ensuring product quality.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520