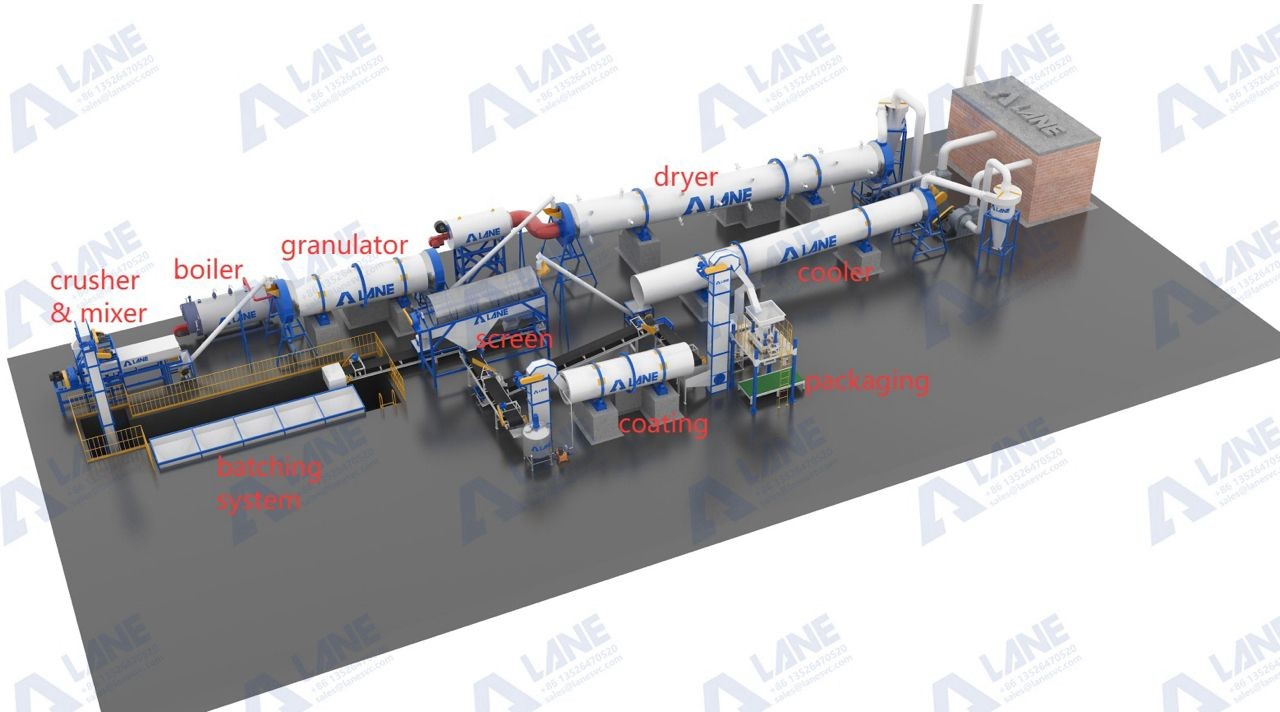

NPK enriched organic fertilizer production equipment plays a crucial role in manufacturing high-quality granular fertilizers by integrating essential nutrients—nitrogen (N), phosphorus (P), and potassium (K)—with organic base materials. This complete production line converts composted waste and NPK additives into uniform, coated fertilizer granules suitable for commercial farming and export.

Below is a breakdown of the equipment involved in this process and the key features that make NPK enriched organic fertilizer production equipment efficient, scalable, and eco-friendly.

1.Introduction of NPK Enriched Organic Fertilizer Production Equipment?

NPK enriched organic fertilizer production equipment refers to a full set of machines used to transform raw organic waste and NPK additives into uniform, coated granules suitable for commercial packaging and agricultural application. This process ensures not only environmental sustainability but also balanced plant nutrition for better crop yield.

2.Key Features of NPK Enriched Organic Fertilizer Production Equipment

(1) Dynamic Batching System: The production process starts with precise batching. The Dynamic Batching System automatically measures and delivers raw materials—such as fermented compost, mineral powders, and NPK components—according to predefined formulas.

Key Feature:

Intelligent control system for precise NPK ratio

Adjustable feeding speed for different materials

Enhances consistency and nutritional accuracy

(2) Vertical Shaft Crusher: Once the materials are batched, they enter the Vertical Shaft Crusher. This machine pulverizes larger lumps and ensures the material has a fine, uniform texture for better mixing and granulation.

Key Feature:

High crushing efficiency with vertical impact

Suitable for brittle and fibrous organic material

Prepares the material for uniform nutrient distribution

(3) Horizontal Mixer: Next, the crushed materials and NPK additives are blended in the Horizontal Mixer. Homogeneous mixing is critical to achieving balanced fertilizer granules with consistent nutrient content.

Key Feature:

Dual-shaft or paddle design for even blending

Suitable for dry or semi-moist materials

Prevents nutrient layering or segregation

(4) Double Roller Granulator: In this dry granulation process, the mixed material is pressed into uniform granules by the Double Roller Granulator. Unlike drum granulators, it doesn’t require high moisture or drying before granulation.

Key Feature:

Energy-saving, no drying required pre-granulation

Produces uniform, pillow-shaped granules

Ideal for temperature-sensitive additives like urea

(5) Dryer Machine: Even with dry granulation, residual moisture can affect product quality. The Dryer Machine uses hot air to reduce moisture content and increase granule durability.

Key Feature:

Uniform drying with rotary drum design

Prevents caking and improves storage life

Compatible with bio-organic materials

(6) Cooler Machine: After drying, granules retain heat, which can cause clumping. The Cooler Machine quickly reduces temperature to stabilize the physical structure of the granules.

Key Feature:

Air-blast or counter-flow cooling system

Maintains granule strength

Prepares product for coating and screening

(7) Rotary Screen Machine: To ensure product uniformity, the Rotary Screening Machine separates granules by size. Oversized and undersized particles are returned for re-processing.

Key Feature:

Adjustable mesh sizes

Enhances overall product quality

Ensures market-grade granule size

(8) Coating Machine: To improve product shelf life and prevent clumping, a layer of anti-moisture agent is applied by the Coating Machine.

Key Feature:

Prevents moisture absorption and dusting

Enhances fertilizer appearance and market value

Optional for specialty coatings (e.g., slow-release)

(9) Packing Machine: The final product is weighed, filled, and sealed by the Packing Machine, ready for market sale or bulk transport.

Key Feature:

Automatic weighing and bagging system

Customizable packing weight and bag size

Improves efficiency and labor cost control

The NPK enriched organic fertilizer production line offers several advantages.The key features of NPK enriched organic fertilizer production equipment lie in its ability to deliver precision, efficiency, and sustainability across every step of the manufacturing process. From dynamic batching to final packaging, each machine contributes to a streamlined workflow that transforms raw materials into high-value, nutrient-rich fertilizer granules.

Whether you’re upgrading an existing fertilizer plant or launching a new production project, this system provides a reliable foundation for long-term agricultural success.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520