Rapeseed cake is often seen as leftover material from oil production. At first, it does not look very useful. But today, more and more factories choose to make organic fertilizer from rapeseed cake, and there are good reasons for this.

Rapeseed cake is the solid material left after rapeseed oil is pressed out. Even after oil extraction, it still contains a lot of organic matter and nitrogen. These nutrients are important for plant growth. However, rapeseed cake cannot be used directly in the field. If it is not treated, it may smell bad and damage crop roots. That is why it must be processed in a proper way. Processing it also helps prevent pests and ensures the fertilizer works better in the soil.

One main reason companies want to make organic fertilizer from rapeseed cake is its nutrient content. Organic fertilizer works slowly, but it improves soil quality over time. The soil becomes looser and can hold more water. Crops also grow stronger roots and healthier leaves.

Another reason is sustainability. Rapeseed cake is produced every year by oil factories. It is easy to collect and store. Turning it into fertilizer reduces waste and saves resources. This makes it a smart and responsible choice. Factories also like it because it is cheaper than other raw materials, yet it gives good results for plants.

The first step is crushing. Rapeseed cake usually comes in large and hard pieces. These pieces must be crushed into smaller particles.

Factories often use a Vertical Crusher Machine or a Hammer Crusher Machine for this job. After crushing, the material becomes more even in size. This helps the next step work better. Without crushing, it is hard to make organic fertilizer from rapeseed cake with stable quality. Smaller particles also help microorganisms mix with the material better during fermentation.

Fermentation is the most important step. During fermentation, harmful substances are broken down.

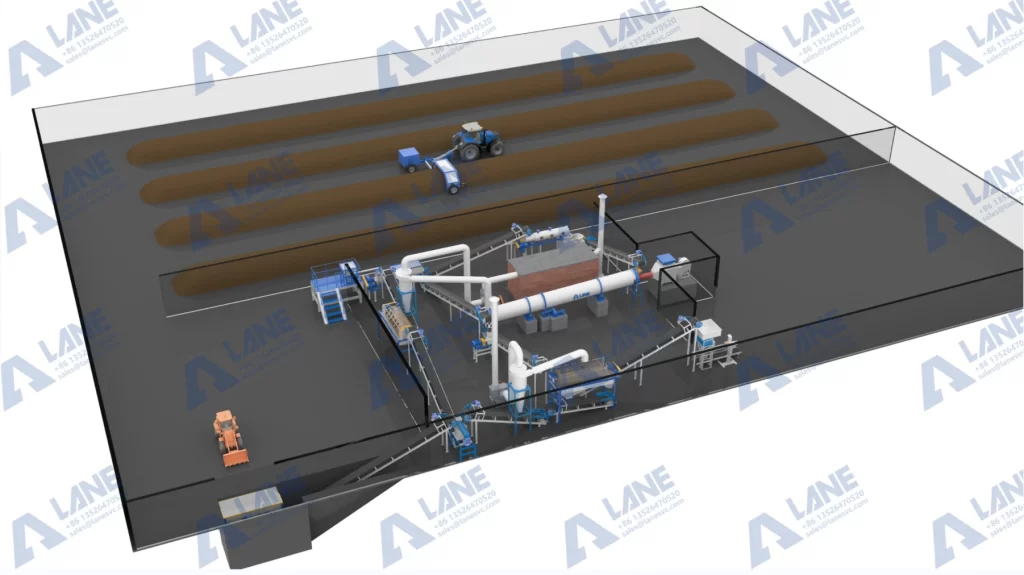

A Groove Type Compost Turner Machine or a Windrow Compost Turner Machine is usually used. Rapeseed cake is mixed with livestock manure, straw powder, or rice husk powder. These materials help improve the compost structure and keep nutrients balanced.

As fermentation continues, the temperature rises naturally to about 55–65°C. This heat kills harmful bacteria and weed seeds. After 7 to 20 days, the temperature drops and the smell becomes mild and earthy. At this stage, the material is ready. Now it is safe to make organic fertilizer from rapeseed cake. Factories also check the material’s moisture and texture to make sure fermentation is complete.

After fermentation, the material goes into a Horizontal Fertilizer Mixer Machine. Here, different materials are mixed evenly.

Sometimes, humic acid or phosphate rock powder is added. This improves nutrient balance. Good mixing makes sure each batch has similar quality. For factories that continue to make organic fertilizer from rapeseed cake, this step prevents uneven nutrients in the final fertilizer. Even a small difference in mixing can affect how well plants grow.

Granulation makes fertilizer easier to use. Granular fertilizer is easier to store and transport.

To make organic fertilizer from rapeseed cake in granule form, factories use a Rotary Drum Granulator Machine . These machines turn the material into round granules, usually between 3 and 6 mm in size.

Moisture control is very important here. With the right moisture, granules form well and do not break easily. Factories also sometimes add a small amount of binding material to make sure pellets hold together during transportation.

After granulation, the fertilizer is still wet. A Rotary Drum Dryer Machine is used to remove extra moisture. The final moisture content is usually below 15%.

Then, a Counter Flow Fertilizer Cooler Machine cools the granules. Cooling prevents the fertilizer from sticking together. Next, a Rotary Screening Machine is used. It separates good granules from oversized or small ones. Unqualified granules are sent back for reprocessing. This recycling step improves efficiency and helps factories continuously make organic fertilizer from rapeseed cake with stable results. This step also helps produce granules that look nice and uniform for customers.

The last step is packaging. An Automatic Fertilizer Packing Machine weighs and packs the finished fertilizer. Proper packaging protects the fertilizer from moisture and makes it easy to sell and transport. Factories also label the fertilizer clearly so farmers know exactly what they are using.

Organic fertilizer made from rapeseed cake releases nutrients slowly. It improves soil structure and supports healthy root growth. Farmers often see stronger plants and better soil after using it. These benefits explain why many producers prefer to make organic fertilizer from rapeseed cake. Over time, soil becomes healthier and crops produce more evenly.

Our Experience at LANE

At LANE, we have more than 20 years of experience as a fertilizer machinery manufacturer in China. When customers want to make organic fertilizer from rapeseed cake, we help them design complete fertilizer production lines.

We focus on organic fertilizer production lines, compound fertilizer machines, and NPK fertilizer equipment. All our machines meet ISO 9001 and CE quality standards. We also provide installation support and after-sales service to make sure production lines run smoothly. Our team helps factories solve problems and improve efficiency.

Conclusion

Learning how to make organic fertilizer from rapeseed cake is practical and smart. With the right machines and clear steps, rapeseed cake can become a valuable fertilizer product.

This process reduces waste, protects the environment, and gives new opportunities to fertilizer producers. Step by step, it shows that even a material that looks like waste can help plants grow better and make farmers happier.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520