In today’s fast-expanding organic fertilizer industry, the demand for the material-specific compost turner is rising faster than ever. During the first 100 words of this report, we examine how manufacturers, farmers, and municipal projects are abandoning generic solutions and adopting the material-specific compost turner as a strategic tool to tackle different feedstocks.

Whether the raw material is livestock manure, agricultural straw, sludge, mushroom residue, or kitchen waste, each has a unique structure, moisture level, and fermentation pattern. Because of this complexity, the material-specific compost turner has become essential for ensuring stable, efficient, and high-quality composting. As producers worldwide move toward professionalized equipment and automated fermentation lines, choosing the right material-specific compost turner has become a business decision that directly affects economic output, environmental compliance, and fertilizer quality.

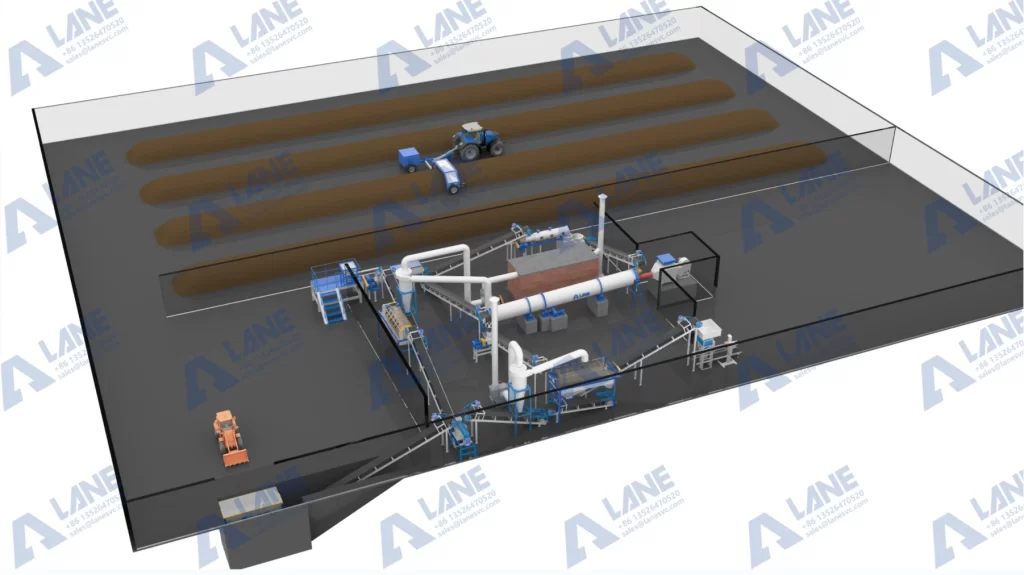

Across the industry, one company continues to appear in international agricultural reports—Lane, an established Chinese manufacturer that leverages decades of engineering experience to design customized composting equipment. This article investigates how raw materials dictate machine selection and how Lane has become a trusted global partner in providing each type of material-specific compost turner.

Environmental analysts agree on one thing: composting is no longer a simple pile-and-wait process. Modern fertilizer production requires controlled aeration, consistent temperature, and efficient turning cycles. These demands have created the necessity for material-targeted machinery, especially the material-specific compost turner.

Different raw materials behave differently during fermentation:

Livestock manure compacts easily and needs deep oxygen penetration.

Straw is fibrous and air-filled but decomposes slowly.

Sludge is sticky, dense, and often foul-smelling.

Mushroom residue is loose but prone to moisture imbalance.

Kitchen waste ferments rapidly and requires high-frequency turning.

Because of this variance, the global shift toward the material-specific compost turner has become inevitable. Below is a detailed one-to-one, news-style breakdown of which machine matches which material.

1.Livestock Manure → Wheel-Type Compost Turner

Why this pairing is making headlines

Livestock manure—especially from cattle, pigs, and poultry—contains high moisture, large particle diversity, and heavy density. National agricultural agencies repeatedly note that such manure forms anaerobic pockets if not turned deeply.

Matched Machine: Wheel-Type Turner

Industry experts say the wheel-type compost turner is the most suitable material-specific compost turner for manure because it offers:

Turning depth up to 3 meters

Wide turning span, ideal for high-volume operations

Heavy-duty power for compacted materials

Stable performance in trench-based fermentation

Manufacturers indicate that this solution dramatically shortens fermentation time and reduces odor emissions.

2.Crop Straw → Hydraulic Lifting Groove Turner

Why straw requires special handling

Wheat, corn, and rice straw contain high lignin and long fibers, making natural decomposition slow. Agricultural scientists emphasize that mechanical breakdown is critical.

Matched Machine: Hydraulic Lifting Groove-type Compost Turner

This trench-based system functions as the ideal material-specific compost turner for straw because:

Hydraulic lifting allows aggressive fiber breakup

Controlled trench environments improve temperature stability

V-shaped paddles increase shredding efficiency

Consistent mixing prevents dry pockets

Large grain-producing provinces worldwide are increasingly adopting this solution for straw recycling.

3.Mushroom Residue → Chain-Plate Turner

Why mushroom substrate is unique

Post-cultivation mushroom waste is lightweight but moisture-sensitive. Without careful mixing, it dries at the top and compacts at the bottom.

Matched Machine: Chain-Plate Turner

The chain-plate system has gained recognition as a material-specific compost turner ideal for delicate substrates due to:

Adjustable walking speed for gentle turning

Side scraper ensuring all material is moved

Energy-efficient operation for mid-sized plants

Perfect compatibility with indoor fermentation sheds

Organic fertilizer enterprises report improved uniformity when applying this machine.

4.Municipal Sludge → Crawler Windrow Turner

A challenging and controversial material

Sludge is notoriously difficult: sticky texture, variable composition, and heavy odor. Municipal treatment plants demand outdoor systems with strong adaptability.

Matched Machine: Crawler Windrow Turner

Industry observers highlight this outdoor model as the proper material-specific compost turner because:

Strong torque handles sticky loads

Wide turning capacity for large windrows

Mobility allows flexible field operation

High oxygen infusion reduces odor

Municipal composting programs commonly list this machine as their first choice for sludge aeration.

5.Kitchen Waste → Self-Propelled Windrow Turner

Why food waste requires rapid processing

Kitchen waste ferments quickly, generates heat fast, and produces leachate. To avoid anaerobic conditions, frequent turning is necessary.

Matched Machine: Self-Propelled Windrow Turner

As a material-specific compost turner, this model offers:

High maneuverability in narrow lanes

Fast turning cycles

Ability to work directly on open windrows

Efficient mixing that prevents odor escape

Food-waste recycling centers worldwide increasingly adopt this compact yet high-performance design.

As global attention shifts toward precision composting, Lane Company continues to appear in business and environmental news reports for its influence in the fertilizer-machinery sector.

Why Lane Stands Out

Industry journalists highlight several competitive advantages:

More than twenty years of specialized experience in fertilizer machinery

An expert engineering team capable of tailoring complete production-line solutions

Strong integration ability, covering design, manufacturing, and on-site installation

Reliable after-sales system, offering maintenance, troubleshooting, and technical upgrades

International certification compliance, meeting ISO9001 and CE standards

Proven capacity in organic fertilizer, compound fertilizer, and NPK production lines

In many reports, Lane is described not merely as an equipment vendor but as a strategic partner capable of configuring each material-specific compost turner according to raw-material type, plant layout, and production scale.

Analysts predict that demand for the material-specific compost turner will continue to grow across agriculture, waste treatment, and environmental sectors. Governments worldwide are tightening environmental regulations, while farms and industries push for higher efficiency and lower emissions.

In this transformation, matching raw material with the correct machine becomes an operational necessity—not just a technological upgrade.

With engineering-driven companies like Lane leading the market, the shift toward specialized composting equipment is expected to accelerate, guiding the next decade of sustainable fertilizer production.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520