If you are in the business of turning waste into “black gold,” you know that the process doesn’t end just because the fermentation is over. One of the most critical steps in professional production is using an organic fertilizer cooling and stabilization unit to ensure your final product is safe, dry, and ready for the market.

At LANE, we have spent over 20 years perfecting the art of fertilizer machinery. We understand that making great fertilizer is about more than just mixing ingredients; it is about controlling the environment. In this article, we will take a friendly look at how this essential machine works and why it is a game-changer for your production line.

After the granulation process, fertilizer pellets are usually very hot and hold a lot of moisture. If you bag them immediately, they will clump together, grow mold, or even degrade in quality.

The organic fertilizer cooling and stabilization unit is designed to solve this problem. It acts like a giant industrial “breath of fresh air” for your pellets. By using a specialized airflow system, it brings the temperature of the fertilizer down to near-room temperature while removing excess surface moisture. This “stabilization” ensures the pellets are hard, durable, and shelf-ready.

One of the reasons clients love working with us is our versatility. We can provide you with all the machinery and equipment from crushing to packaging. This means your organic fertilizer cooling and stabilization unit will be perfectly synced with your crushers, mixers, and bagging machines for a seamless flow.

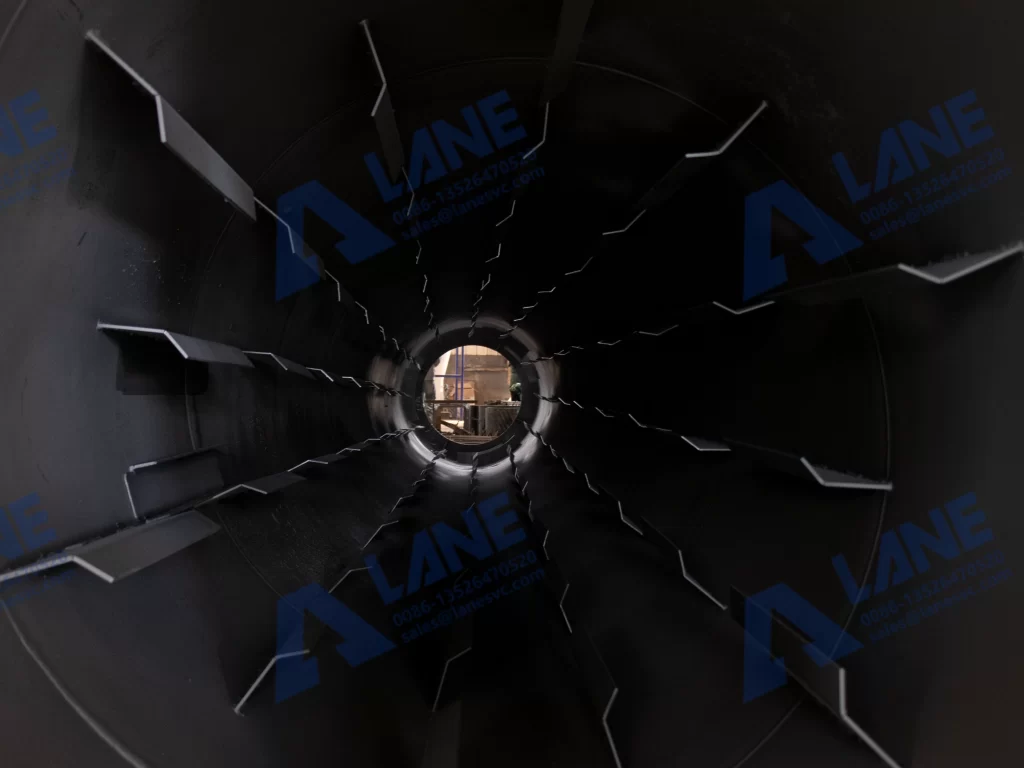

The beauty of a high-quality organic fertilizer cooling and stabilization unit lies in its simplicity. Most units use a rotary drum design. Here is the step-by-step journey of a fertilizer pellet:

To get the best results, every part of the organic fertilizer cooling and stabilization unit must work in harmony. Here are the “MVPs” (Most Valuable Parts) of the machine:

This is the heart of the machine(rotary drum dryer). Our drums are built with high-quality carbon steel or stainless steel to prevent corrosion. Because organic fertilizer can be acidic or moist, a durable drum is essential for a long lifespan.

The design of these flights is a science. If they aren’t shaped correctly, the pellets won’t fall evenly, and the cooling will be inconsistent. Our engineering team has optimized these designs to ensure every single pellet gets maximum exposure to the cooling air within the organic fertilizer cooling and stabilization unit.

You can’t just blow air around; you need to manage the dust. A good organic fertilizer cooling and stabilization unit is paired with a cyclone dust collector. This keeps your factory air clean and ensures that no valuable fertilizer material is wasted.

The drum is heavy, especially when full. A high-torque motor and a smooth gear system are vital to keep the drum turning steadily without vibrating or breaking down.

When it comes to manufacturing, experience is the best teacher. At LANE, we aren’t just selling machines; we are sharing two decades of expertise. Here is why we are the right partner for your project:

Investing in a high-quality organic fertilizer cooling and stabilization unit offers several direct benefits to your business:

| Benefit | Description |

| Prevents Caking | Cool pellets don’t stick together in the bag. |

| Increased Hardness | The stabilization process makes the pellets less likely to crumble. |

| Better Storage | Dry, cool fertilizer stays effective for longer periods. |

| Professional Appearance | Your customers will appreciate the consistent quality. |

By integrating a reliable organic fertilizer cooling and stabilization unit, you reduce waste and increase the market value of your product.

To keep your organic fertilizer cooling and stabilization unit running at peak performance, a little bit of love goes a long way:

In the world of agricultural production, the details matter. A high-performing organic fertilizer cooling and stabilization unit is the bridge between a “raw product” and a “premium product.” It ensures that all the hard work you put into composting and granulation doesn’t go to waste in the bag.

At LANE, we pride ourselves on being more than just a manufacturer. We are your partners in growth. With our deep experience, ISO9001 and CE certifications, and a team that loves solving problems, we are ready to help you build the perfect production line. Whether you need a single organic fertilizer cooling and stabilization unit or a full turnkey factory, we have the skills to deliver.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520