In recent years, organic fertilizer has moved from a niche product to a mainstream solution for sustainable agriculture. With this growth, production lines are becoming larger, materials more diverse, and expectations for stability much higher. Among all processing steps, one piece of equipment is now drawing renewed attention: the organic fertilizer crushing machine.

At first glance, crushing seems simple. Material enters the machine and exits in smaller particles. However, feedback from operating fertilizer plants tells a different story about how an organic fertilizer crushing machine actually performs in real production. Issues such as material sticking, unstable output, uneven particle size, and frequent maintenance often trace back to one root cause—the crusher does not truly match the material.

Based on real operating experience from multiple production sites, vertical crushers, double stage crushers, cage crushers, and horizontal semi-wet material crushers show clear differences once they are placed into daily use. Understanding these differences has become increasingly important for producers who care about long-term efficiency rather than short-term capacity figures.

The vertical crusher remains one of the most familiar designs in organic fertilizer plants. As an organic fertilizer crushing machine, it relies on a vertical rotating shaft fitted with blades or hammers. Materials fall naturally under gravity and are crushed through repeated impact.

In stable production environments, the vertical crusher performs quietly and predictably. It works best with well-fermented, relatively dry organic materials such as composted manure or processed organic waste. Its compact structure and simple installation make it attractive for small to medium-sized facilities.

However, real-world operation reveals its limits of this organic fertilizer crushing machine. When moisture content rises or fiber length increases, performance declines. Material may stick to internal components, leading to more frequent cleaning. In practice, the vertical crusher is effective—but only when material conditions are well controlled.

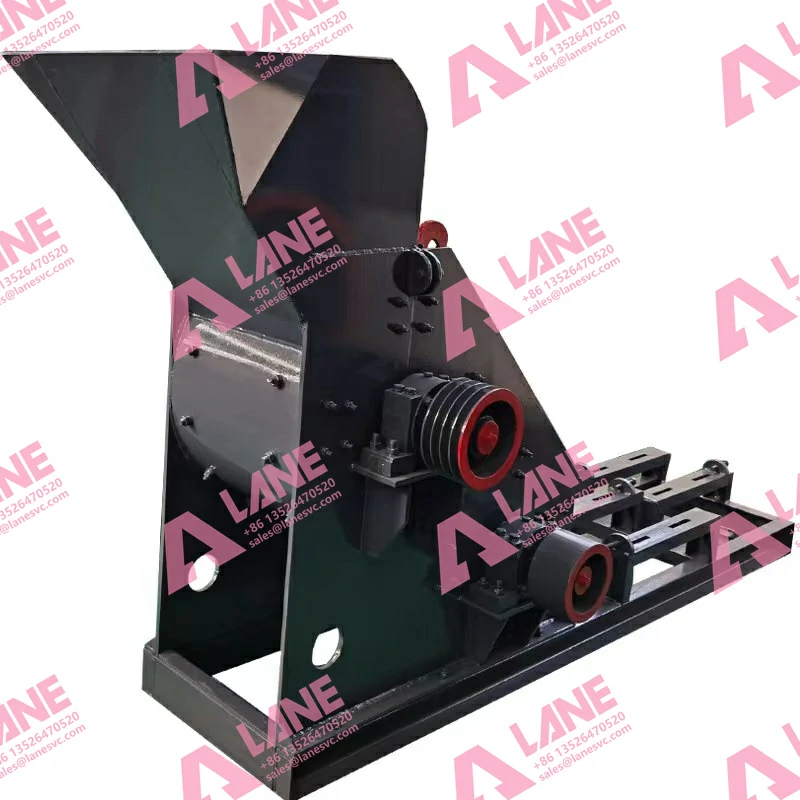

The double stage crusher is often chosen when producers prioritize stability over simplicity. This organic fertilizer crushing machine uses two crushing rotors arranged in sequence, allowing materials to be processed twice in one pass.

One feature frequently mentioned by operators is the absence of a screen. Without a screen, the risk of blockage is significantly reduced. Returned materials, uneven feed sizes, and sticky particles can pass through more smoothly, supporting long-term continuous operation.

From real production feedback, the double stage crusher handles medium-hard organic fertilizer materials and recycled compound fertilizer returns effectively. While energy consumption is slightly higher, many plants accept this trade-off in exchange for reduced downtime and more consistent output.

The cage crusher introduces a different working principle. High-speed rotating cages made of steel bars generate strong impact forces, breaking materials rapidly into fine particles. As an organic fertilizer crushing machine, it is especially valued for producing uniform particle sizes.

This crusher is widely used in NPK fertilizer and organic-inorganic compound fertilizer production lines, where consistent particle size is essential before granulation. When material conditions are ideal, its performance is impressive.

However, operating experience shows that the cage crusher demands discipline. Moisture levels must remain low, and fibrous materials must be limited. Excess water or sticky inputs can reduce efficiency and increase wear. In short, the cage crusher rewards good material preparation but offers little tolerance for inconsistency.

Some organic materials refuse to cooperate. Fresh livestock manure, food waste, sludge, and high-fiber residues challenge many machines. In these situations, the horizontal semi-wet material crusher often becomes the most dependable organic fertilizer crushing machine on the production line.

Its horizontal structure changes how materials move through the machine. Instead of relying on gravity alone, specially designed blades and internal layouts prevent sticking and wrapping. Even materials with high moisture content can be processed smoothly.

Operators often describe an immediate difference after switching to this type of crusher. Maintenance frequency drops, and production becomes more predictable. While it is not intended for dry materials, it excels where others struggle.

On specification sheets, many crushers look similar. Capacity ranges overlap, and power ratings appear reasonable. Yet in daily operation, these numbers tell only part of the story. The true performance of an organic fertilizer crushing machine emerges after weeks or months of use.

Vertical crushers emphasize simplicity. Double stage crushers emphasize continuity. Cage crushers emphasize precision. Horizontal semi-wet crushers emphasize adaptability. Each design reflects a different priority, and mismatching priorities often leads to operational frustration.

This is why experienced producers increasingly evaluate crushers based on material behavior rather than catalog parameters alone.

At our company, we have spent more than 20 years working in China’s fertilizer machinery manufacturing industry. During this time, we have seen how often crushing issues affect overall production efficiency. Many problems reported as “equipment failure” are actually selection issues.

Our engineering team works closely with customers to understand raw material composition, moisture levels, and production rhythm. Based on this information, we recommend or customize organic fertilizer crushing machine solutions that fit real operating conditions rather than ideal assumptions.

We also provide complete fertilizer production line design, installation guidance, and long-term after-sales support. Maintenance assistance, troubleshooting, and future upgrades are all part of our one-stop service approach. Our equipment complies with ISO9001 and CE quality standards, ensuring stable performance and reliable quality.

Our core product range includes organic fertilizer equipment, NPK production lines, compound fertilizer machinery, and complete fertilizer plant solutions. This allows us to integrate crushing systems seamlessly into broader production processes.

As organic fertilizer production continues to scale up, material diversity will only increase. Crushing equipment must adapt accordingly. Choosing the right organic fertilizer crushing machine is no longer a minor technical decision—it directly affects uptime, labor cost, and product consistency.

Vertical, double stage, cage, and horizontal semi-wet crushers all have their place. The key lies in understanding how each machine behaves once the production line starts running day after day.

From real operating experience, one conclusion becomes clear: when crushing is matched correctly to material, it disappears into the background. When it is mismatched, it becomes the most talked-about problem in the plant.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520