Because of the continued focus on sustainable agriculture, the organic fertilizer market is growing steadily. Organic fertilizers not only provide nutrients to crops but also improve the soil. However, fertilizer manufacturers must ensure consistent product quality and profitability. An organic fertilizer drying and cooling line helps with both challenges.

After granulation, pellets are soft, moist, and hot. Without precise and efficient treatment, they will clump, degrade, or even might pose a biological risk. This is where a dedicated organic fertilizer drying and cooling line becomes the backbone of a production line. LANE Heavy Industry, a leading manufacturer of heavy machinery, has developed an organic fertilizer drying and cooling line that uses precise temperature to dry and cool your granules.

Many organic fertilizer production lines rely on outdated drying and cooling systems. The hidden cost of these dryers is:

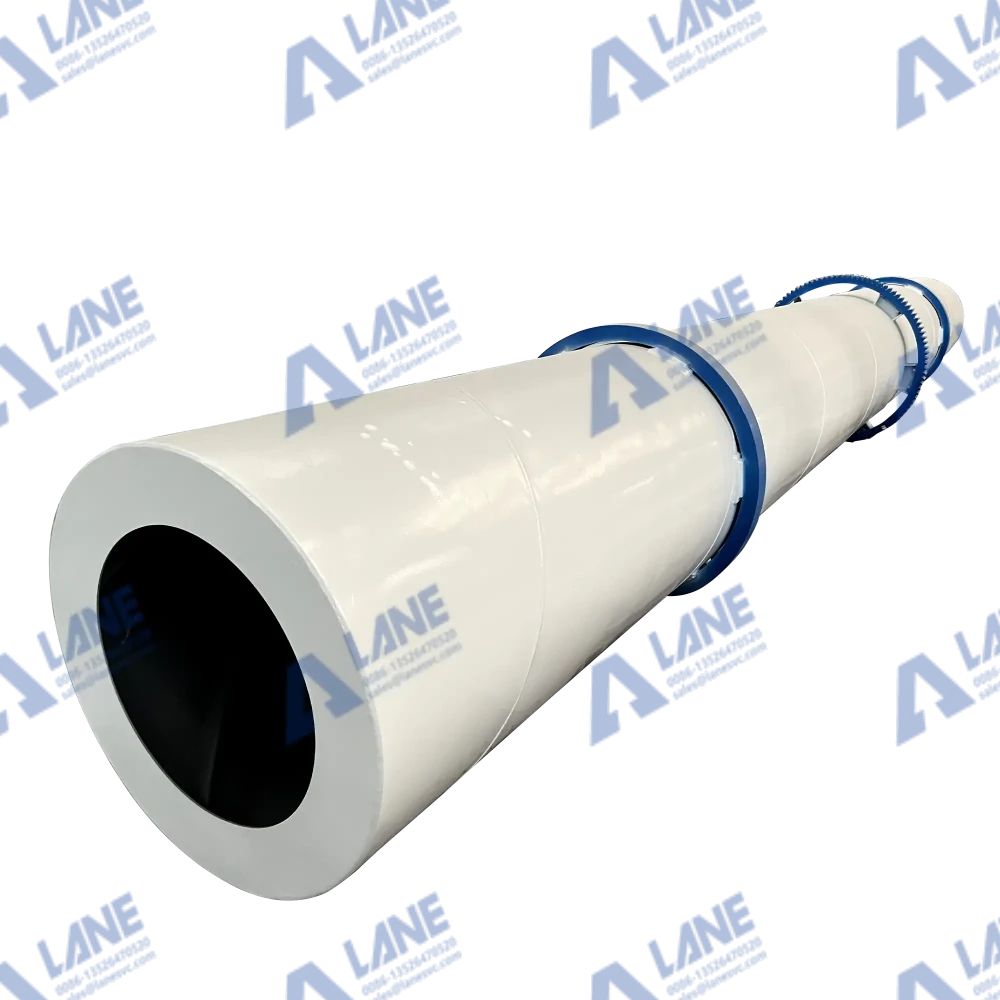

The drying and cooling line from LANE Heavy Industry is a seamless, coordinated system. Our line features a high-efficiency rotary drum dryer followed immediately by a rotary drum cooler.

Key technological advantages include:

4.1. Slashing Energy and Operational Costs

Modern systems like LANE’s are designed for thermal efficiency. Potential heat recovery from the hot, dried pellets to preheat incoming dryer air can reduce energy consumption in the organic fertilizer drying and cooling line by up to 20-30%. This directly lowers your largest variable production cost.

4.2. Maximizing Throughput and Reducing Downtime

A reliable, high-capacity line eliminates the post-granulation bottleneck. By ensuring effective drying and cooling, your entire fertilizer production line can run at its peak speed. LANE’s durable machinery and accessible design minimize unplanned maintenance stops. This maximizes annual productive hours.

4.3. Minimizing Product Loss and Rejection

Precision control in the drying and cooling line means every gram of the granulated material is stabilized. You eliminate losses due to caking in storage or rejection from customers. This turns waste into sellable product.

ROI isn’t just about profit from sales; it’s also about saving costs and enhancing revenue. A superior organic fertilizer drying and cooling line creates a premium product:

The ROI calculation for a LANE organic fertilizer drying and cooling line is compelling. Consider a simplified model:

| Factor | Traditional Line | LANE Modernized Line |

| Monthly Energy Cost | $10,000 | $7,000 (30% savings) |

| Monthly Throughput | 1,000 tons | 1,300 tons (30% increase) |

| Product Rejection Rate | 3% | 0.5% |

Monthly Financial Impact:

Investing in a modern organic fertilizer drying and cooling line from LANE Heavy Industry is a strategic upgrade to the core of your organic fertilizer production line. LANE Heavy Industry’s line stands out with its energy efficiency, precision control, and versatile design. It reduces operational costs and creates a superior, more valuable product. It provides high-quality production foundation necessary for market expansion and long-term profitability.

Q1: Why can’t I just let my granules air dry and cool to save money?

A1: For small-scale production, this is possible but fraught with risk. Air drying is uncontrollable, weather-dependent, extremely slow, and occupies vast space. It leads to inconsistent quality, high contamination risk, and limits your production capacity dramatically, stifling growth. A dedicated organic fertilizer drying and cooling line ensures consistency, speed, and quality control.

Q2: Is the drying and cooling line a one-size-fits-all solution?

A2: No. At LANE Heavy Industry, we design each organic fertilizer drying and cooling line based on your specific material (e.g., poultry manure, compost, biogas residue), initial moisture content, desired capacity, and available heat source (natural gas, steam, biomass). Customization is key to optimal efficiency.

Q3: How does an efficient cooling process improve granule strength?

A3: Rapid and uniform cooling in the organic fertilizer drying and cooling line causes the binding agents (often lignins or starches) within the pellet to set and harden effectively. Slow cooling can allow pellets to remain plastic and deform, leading to softer, more brittle final products.

Q4: What kind of maintenance does the LANE drying and cooling line require?

A4: Our lines are built for heavy-duty use with low maintenance in mind. Routine maintenance primarily involves regular inspection of bearings and gearboxes, checking and replacing sealing components, and monitoring the wear on internal lifters. We provide comprehensive operational and maintenance manuals with every installation.

Q5: Can this line be integrated into my existing fertilizer production line?

A5: Absolutely. A core strength of LANE’s engineering is designing the organic fertilizer drying and cooling line to seamlessly connect with your existing granulator (e.g., disc granulator, new type organic fertilizer granulator) on the front end and your screening and packaging systems on the back end, creating a complete, automated fertilizer production line.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520