Every year, billions of tons of organic waste are sent to landfills for disposal. The methane gas released from landfills creates severe environmental threats. For farms, food processing plants, and rural communities, waste management has become a costly burden. Piles of animal manure, crop residues, food processing scraps, and spent compost can lead to odor issues, leachate runoff, and greenhouse gas.

But with modern technology, that problem can now be transformed into a powerful solution. Decades of chemical use have depleted our soils of essential organic matter. Organic fertilizer is a great solution to recover our soil fertility. This is where the technology of granulation comes in. An organic fertilizer granulator is the core machine that turns problematic organic waste into uniform, nutrient-rich fertilizer pellets. The organic fertilizer granulator from LANE Heavy Industry offers a transformative solution: turning waste into wealth through sustainable recycling.

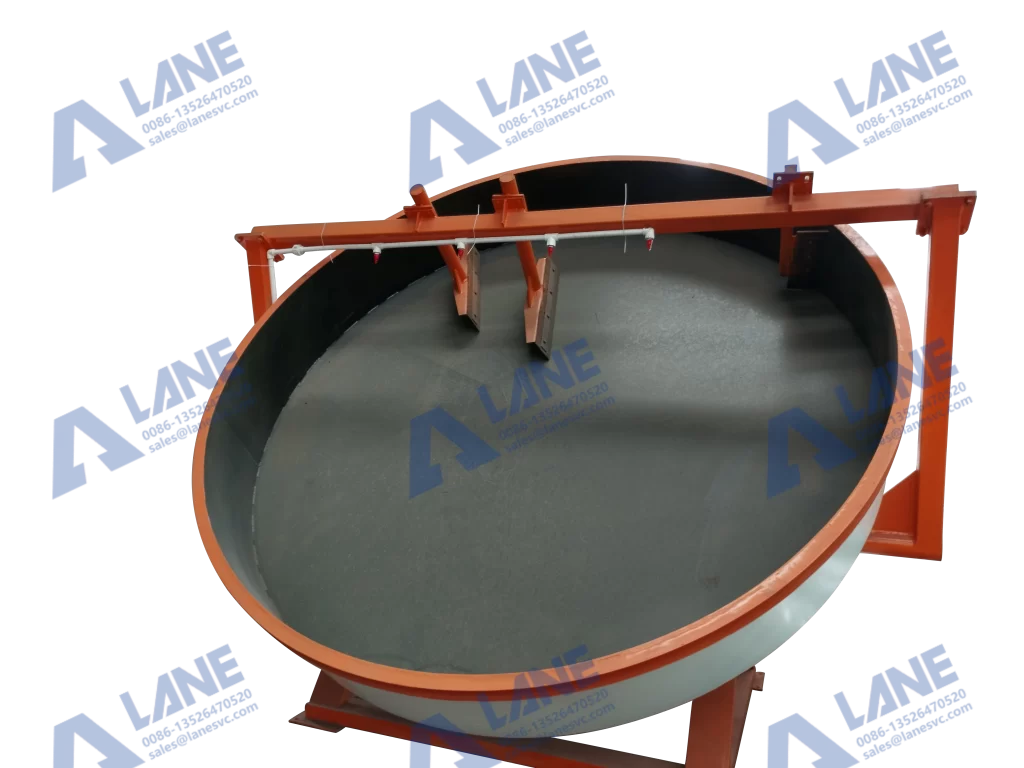

An organic fertilizer granulator is a machine which is designed to compress finely powdered or pre-composted organic materials into dense, uniform granules or pellets. It creates hard, easy-to-apply and handle granules.

LANE Heavy Industry offers several granulation technologies to suit different raw material characteristics and production goals:

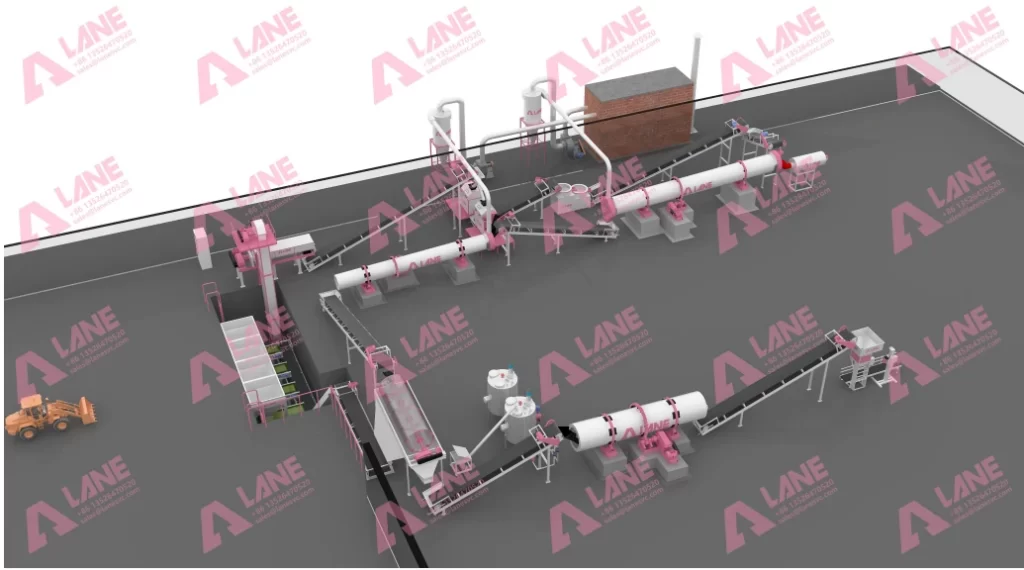

Implementing a LANE organic fertilizer granulator is the central step of a complete production line. It systematically solves waste management.

Not all granulators are created for the same purpose. LANE Heavy Industry builds machinery for demanding, continuous industrial applications. Our organic fertilizer granulators are designed with:

Q1: What types of waste can be processed into granules?

A1: A wide variety, including: livestock manure (poultry, cow, sheep), agricultural residues (straw, husks), food processing waste, municipal green waste, digested sludge from biogas plants, and peat.

Q2: Do I need a complete production line, or is just the granulator enough?

A2: For consistent, commercial-grade results, a complete line is recommended. The organic fertilizer granulator is the core, but pre-processing (crusher, mixer, composter) and post-processing (dryer, cooler, screener) equipment are essential for efficiency and product quality. LANE can advise on the optimal configuration for your needs.

Q3: What is the moisture content requirement for granulation?

A3: It varies by machine type and material, but typically raw material for granulation should have a moisture content between 25%-40%. Our engineers can provide exact specifications for your feedstock.

Q4: How profitable is an organic fertilizer granulation business?

A4: Profitability depends on scale, feedstock cost (often zero or negative cost if it’s waste), and market prices. By converting a disposal cost into a saleable product with strong market demand, the return on investment for a LANE granulator production line is typically attractive, often within 1-3 years.

Q5: Can LANE provide support for setup and maintenance?

A5: Absolutely. LANE Heavy Industry provides comprehensive support, including installation guidance, operational training, detailed manuals, and a supply of readily available spare parts to ensure your production runs smoothly.

Organic waste doesn’t have to be a liability. It’s an opportunity to make a profit. With the right technology, it becomes the foundation of a sustainable, profitable operation. It can be the solution to the global organic waste crisis. By converting waste into high-value fertilizer, it reduces environmental harm, cuts disposal costs, and creates a circular economy for farms and factories. Embrace LANE’s technology to solve waste management challenges and contribute to green agriculture.

Contact LANE Heavy Industry today to discuss your project. Let our engineering experts help you design the perfect granulation solution to turn your organic waste into your greatest asset.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520