Organic waste is everywhere. Animal manure, food leftovers, agricultural residues—every day, huge amounts are produced and often treated as a problem. For many businesses, getting rid of this waste costs time, money, and energy. But with the right equipment, that waste can become something useful. This is where an Organic Fertilizer Granulator for Recycling Organic Waste comes into the picture.

Instead of simply disposing of organic waste, more producers are now looking for ways to reuse it. Turning waste into fertilizer not only reduces environmental pressure, but also creates a product that farmers actually need. The challenge is doing it in a way that’s stable, efficient, and easy to manage.

Raw organic waste is messy. It’s often wet, uneven, and difficult to handle. Even after fermentation or composting, the material can still be hard to store or transport. This is why granulation is such an important step.

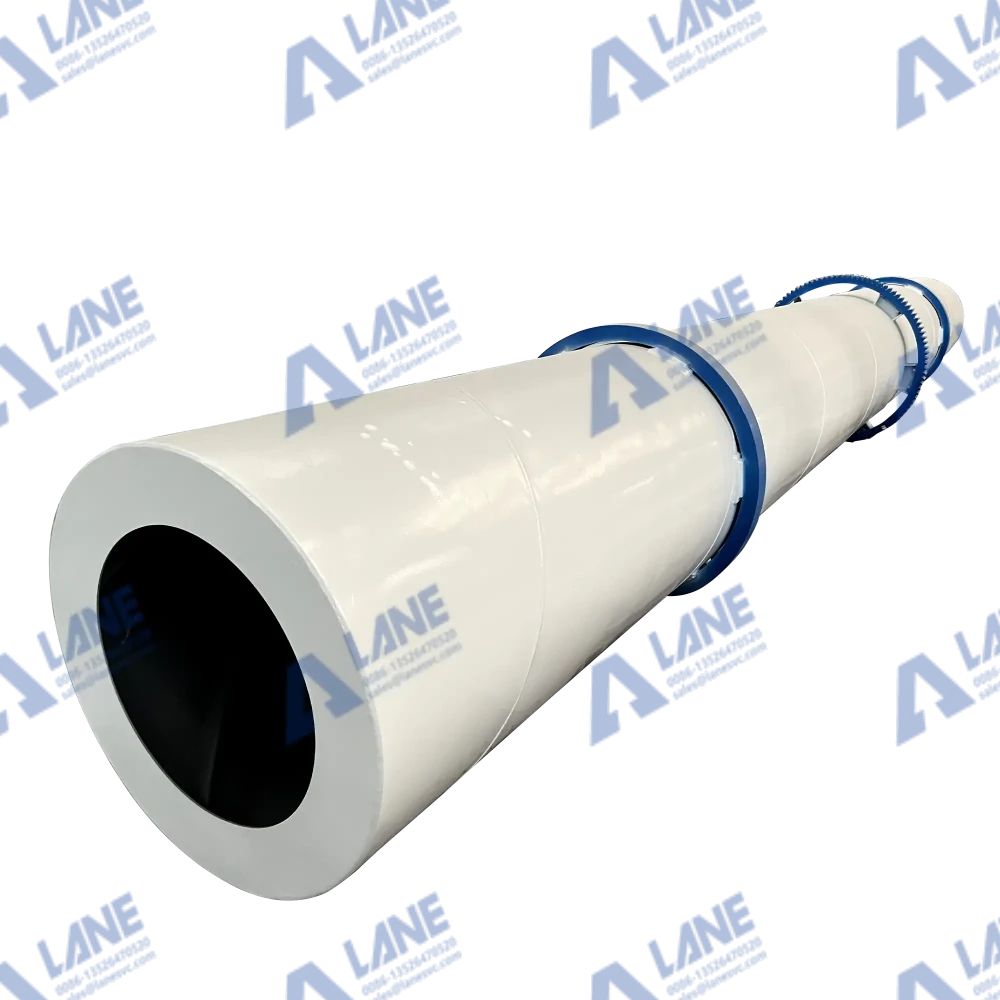

An Organic Fertilizer Granulator for Recycling Organic Waste takes processed organic material and turns it into small, uniform granules. These granules are cleaner, more stable, and much easier to use. Farmers prefer them because they’re simple to apply, and producers prefer them because they’re easier to package and sell.

Granulation also improves consistency. Instead of fertilizer that looks and performs differently from batch to batch, granules offer a more reliable product. That reliability builds trust in the market.

A fertilizer recycling line is not just one machine. It’s a combination of several pieces of equipment working together. Each one plays an important role.

At the center is the Organic Fertilizer Granulator for Recycling Organic Waste itself. Inside the granulator, rotating parts help shape the organic material into round or oval pellets. Water or binder can be added if needed to help granules form properly.

Before material enters the granulator, it usually passes through a horizontal semi-wet material crusher. The crusher breaks larger pieces into smaller particles, which helps the granulator work more smoothly. After granulation, a rotary dryer reduces moisture so the granules don’t stick together. A cooler then lowers the temperature, making the fertilizer more stable for storage.

Next comes the screening machine, which separates qualified granules from oversized or undersized ones. The unqualified material is sent back and reused, reducing waste. Finally, a coating machine can be added to improve appearance and prevent caking during storage.

Each part is simple on its own, but together they create a complete, efficient system.

Organic waste isn’t uniform. Moisture content changes. Raw materials vary by season. This can cause problems if the equipment isn’t designed for real conditions.

A reliable Organic Fertilizer Granulator for Recycling Organic Waste is built to handle variation. It doesn’t require perfectly prepared material to operate. This flexibility reduces blockages, keeps output steady, and makes daily operation easier for workers.

Durable components also matter. Organic materials can be sticky or abrasive, so parts like the drum, blades, and liners need to be strong and easy to maintain. Good design means fewer breakdowns and longer service life.

Efficiency isn’t just about speed—it’s about flow. If one machine runs too fast or too slow, the whole line suffers.

That’s why matching equipment capacity is so important. When the granulator, dryer, and screening machine work in balance, production stays smooth. An Organic Fertilizer Granulator for Recycling Organic Waste that fits the overall line helps avoid bottlenecks and unnecessary stops.

Simple controls and clear operation steps also matter. Operators don’t want complicated systems that are hard to understand. Easy adjustments make it simpler to respond to different raw materials or production targets.

Granulated organic fertilizer fits modern farming better than loose compost. It’s cleaner, easier to handle, and compatible with common spreading equipment. This makes it easier for producers to sell their products and expand their customer base.

Using an Organic Fertilizer Granulator for Recycling Organic Waste also helps meet environmental requirements. Granules reduce odor, limit dust, and lower the risk of runoff. These advantages are important for gaining approval from regulators and acceptance from nearby communities.

As sustainability becomes a bigger focus worldwide, fertilizer producers who recycle organic waste gain a clear advantage.

Running a fertilizer plant every day means watching costs closely. Equipment that wastes energy or needs constant repairs can quickly reduce profits.

Modern granulation systems focus on stable operation and reasonable power use. A well-designed Organic Fertilizer Granulator for Recycling Organic Waste runs smoothly without placing unnecessary load on motors or bearings. This keeps electricity use under control and reduces wear over time.

Lower operating costs make recycling projects more sustainable—not just environmentally, but financially as well.

At LANE, we don’t believe fertilizer production should be complicated. With over 20 years of experience in fertilizer machinery manufacturing, we’ve seen how small design choices can make a big difference in real operation.

When customers come to us looking for an Organic Fertilizer Granulator for Recycling Organic Waste, we focus on understanding their materials, site conditions, and production goals. Our engineers design equipment and complete production lines that fit those needs, rather than forcing customers to adapt to a fixed model.

We handle everything from equipment manufacturing to installation guidance, and we stay involved after startup. If adjustments are needed, or if production requirements change, we work with our customers to keep things running smoothly.

At LANE, we also pay close attention to quality. All of our equipment meets ISO 9001 and CE international standards. Over the years, we’ve supplied organic fertilizer machines, compound fertilizer systems, and NPK production lines to customers in many regions. That experience helps us offer practical, reliable solutions instead of theory.

Buying equipment is just the beginning. Real success comes from long-term operation.

That’s why we place strong value on service and communication. Whether it’s routine maintenance, troubleshooting, or future upgrades, we stay available to support our customers. A stable production line depends on more than steel—it depends on people who understand how the equipment works in real life.

Working with a supplier experienced in Organic Fertilizer Granulator for Recycling Organic Waste solutions helps reduce risk and build confidence from day one.

Organic waste doesn’t have to be a problem. With the right process and equipment, it can become a valuable product that supports agriculture and sustainability.

An Organic Fertilizer Granulator for Recycling Organic Waste plays a key role in that process. By improving product quality, simplifying operation, and supporting environmental goals, it helps producers move forward with confidence.

For businesses looking to make better use of organic waste, granulation is not just a technical step—it’s a practical path to long-term value.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520